Photovoltaic module, photovoltaic adhesive film and preparation method thereof

A photovoltaic module and adhesive film technology, which is applied in photovoltaic power generation, electrical components, semiconductor devices, etc., can solve the problems that the adhesive film is prone to slipping, affects the production speed and yield of photovoltaic modules, and achieves the effect of increasing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

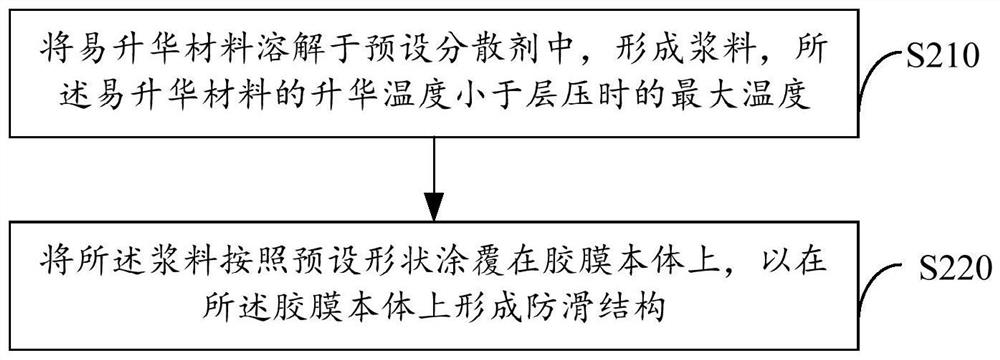

[0044] The present invention also provides a method for preparing the above-described photovoltaic film, see figure 2 , Including the following steps:

[0045] Step S210: Dissolving the Easy Sub-Material Material in the preset dispersant, forming a slurry, the sublimation temperature of the elastnics material is less than the maximum temperature of the lamination;

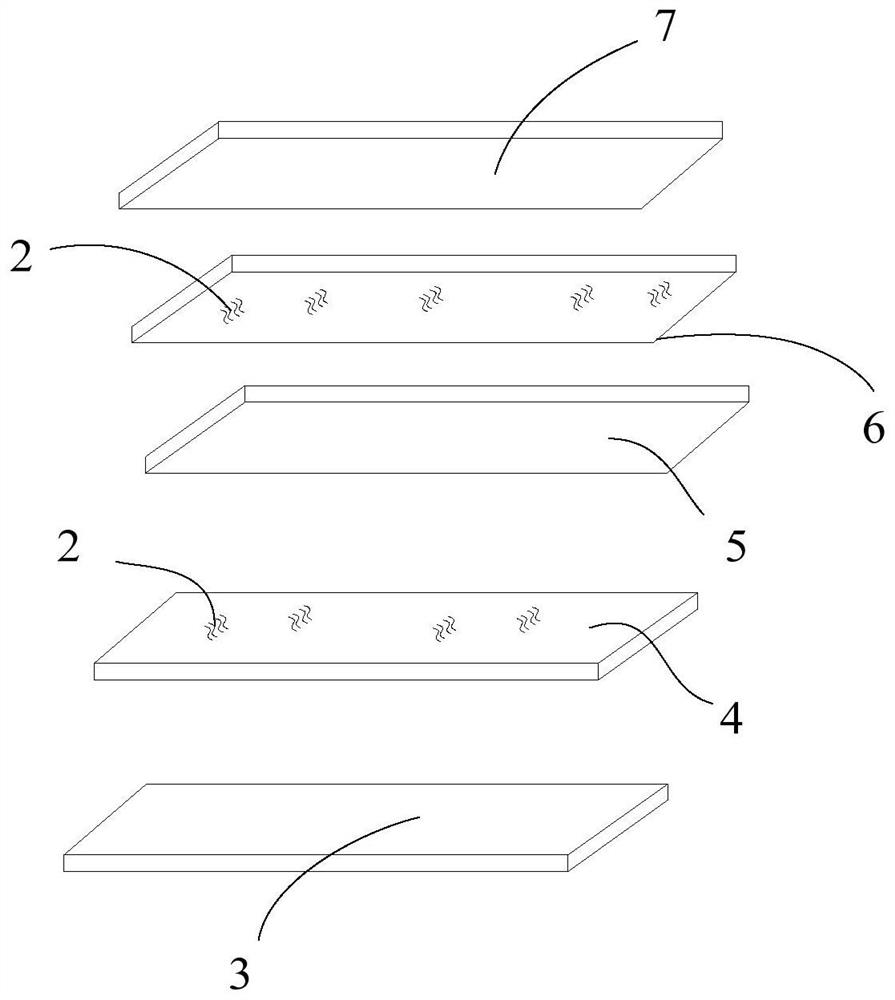

[0046] Specifically, the Yi Limited material is one or more of the nap, trichloride or anthracene, by providing a surface of the cell sheet 5 of naphthalene, aluminum chloride and the silica material, conductive silver paste (Al, Ag), The material such as a tin copper strap (Sn, Pb) is difficult to react, and after lamination of laminated flow, naphthalene or trichloride, it can effectively avoid the effect of residual substance to effectively affect the performance of the photovoltaic assembly. Correspondingly, the preset dispersant comprises a N-methylpyrrolidone solvent (NMP solvent) of polyvinylidene fluoride (PVDF)...

Embodiment 1

[0056] (1) Preparation of anti-skid slurry:

[0057] 10 g naphthalene (naphthalene 25 ° C at room temperature, the sublimation phenomenon) N-methylpyrrolidone solvent (NMP solvent), thoroughly stirred, mixed, mixed uniform, forming a slurry;

[0058] (2) Preparation of anti-skid pattern photovoltaic film:

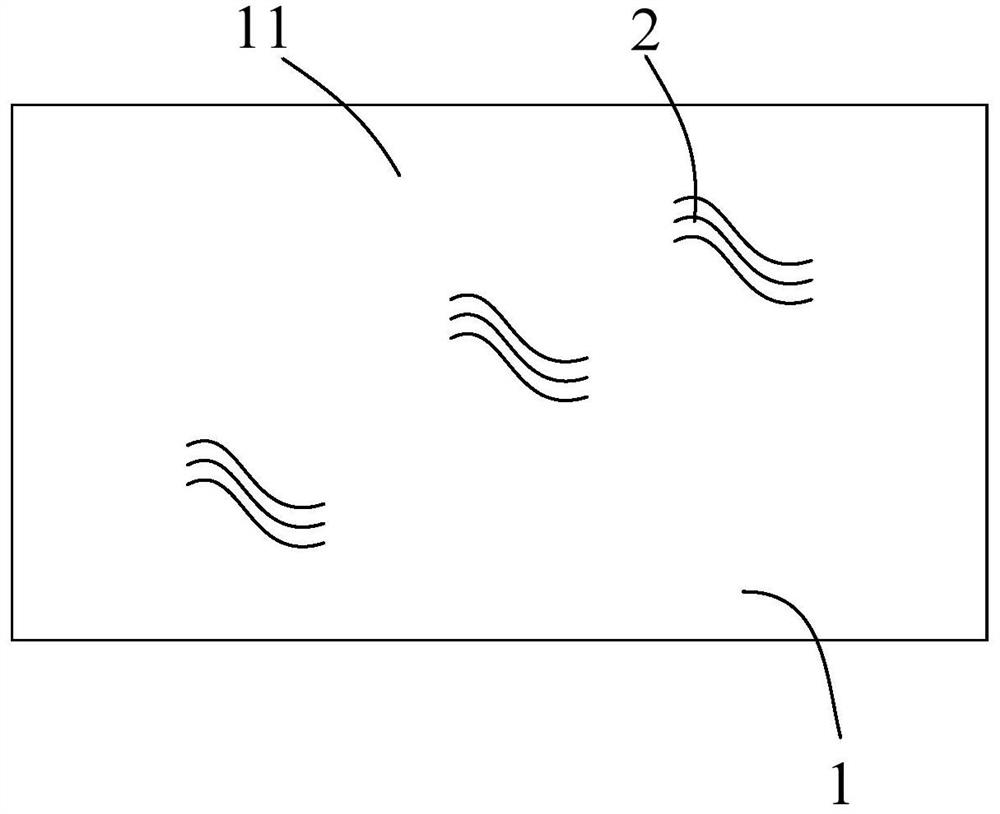

[0059] The pulp film is attached to the hollow film in the preset shape, and the slurry is added at the hollow film of the hollow film. After the slurry is cured, the hollow film is removed. A non-slip structure 2 is formed on the film body 1, wherein the preset shape is a wave shape.

Embodiment 2

[0061] (1) Preparation of anti-skid slurry:

[0062] 10 g of trichloride (sublimation temperature 178 ° C) was dissolved in 20 ml of polyvinylidene fluoride (PVDF) N-methylpyrrolidone solvent (NMP solvent), thoroughly stirred, mixed uniform, mixed, forming a slurry;

[0063] (2) Preparation of anti-skid pattern photovoltaic film:

[0064] In the film body 1 (PoE), it is attached to the hollow film in the preset shape, in which the hollow position is disposed at intervals of adjacent two semiconductor sheets, and the pulp is added to the hollow film. When the slurry is cured, the hollow film is removed to form a non-slip structure 2 on the glue film body 1, wherein the preset shape is a wave shape.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com