Material pressing device for probe pipe orifice forming

A technology of pressing device and nozzle, which is applied in the direction of positioning device, manufacturing tools, metal processing machinery parts, etc., can solve the problems of difficult to ensure the position of the product to be processed, low production capacity, etc., and achieve the effect of ensuring consistency and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024]Hereinafter, the embodiments of the present invention will be described in detail with examples, so as to fully understand and implement the implementation process of how the present invention applies technical means to solve technical problems and achieve technical effects.

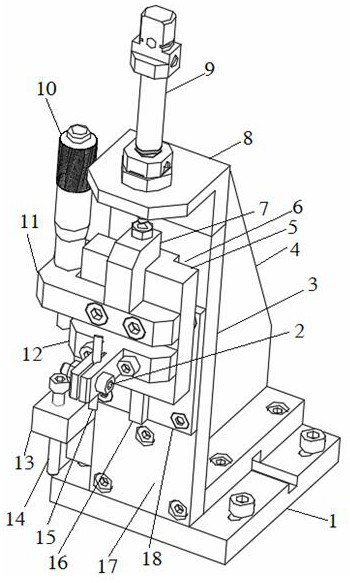

[0025]Such asfigure 1 As shown, a pressing device for forming a probe nozzle of the present invention is mainly composed of the following components:

[0026]A bracket 3,

[0027]A slider 5, which is slidably arranged on one side of the bracket 3;

[0028]A driving mechanism 9, which is arranged at the upper end of the bracket 3 and connected with the slider 5;

[0029]A thimble 15 is arranged on the slider 5.

[0030]The pressing device for forming the probe nozzle of the present invention first loads the probe into the fixture before working, and then moves the thimble 15 down through the driving mechanism 9, and the thimble 15 pushes the probe below it into the fixture. After transporting the probe to the preset positi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com