A dust-proof trolley for construction engineering

A construction engineering and anti-dust technology, which is applied to trolleys, single-axis trolleys, motor vehicles, etc., can solve the problems that the trolleys do not have the function of dust suppression, and achieve the effects of improving the construction environment, reducing replacement costs, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

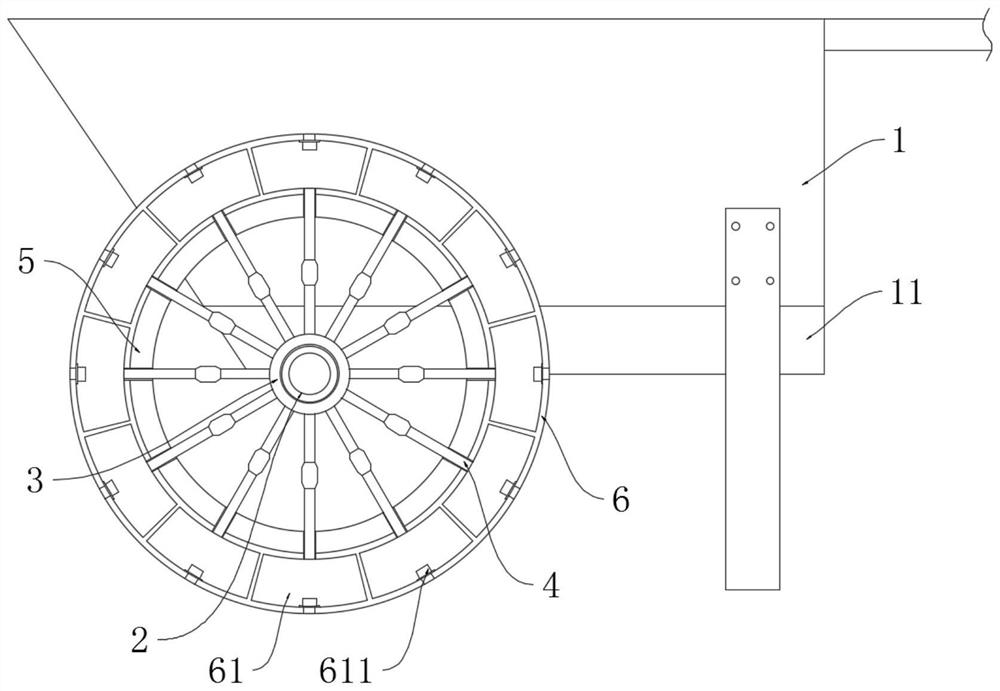

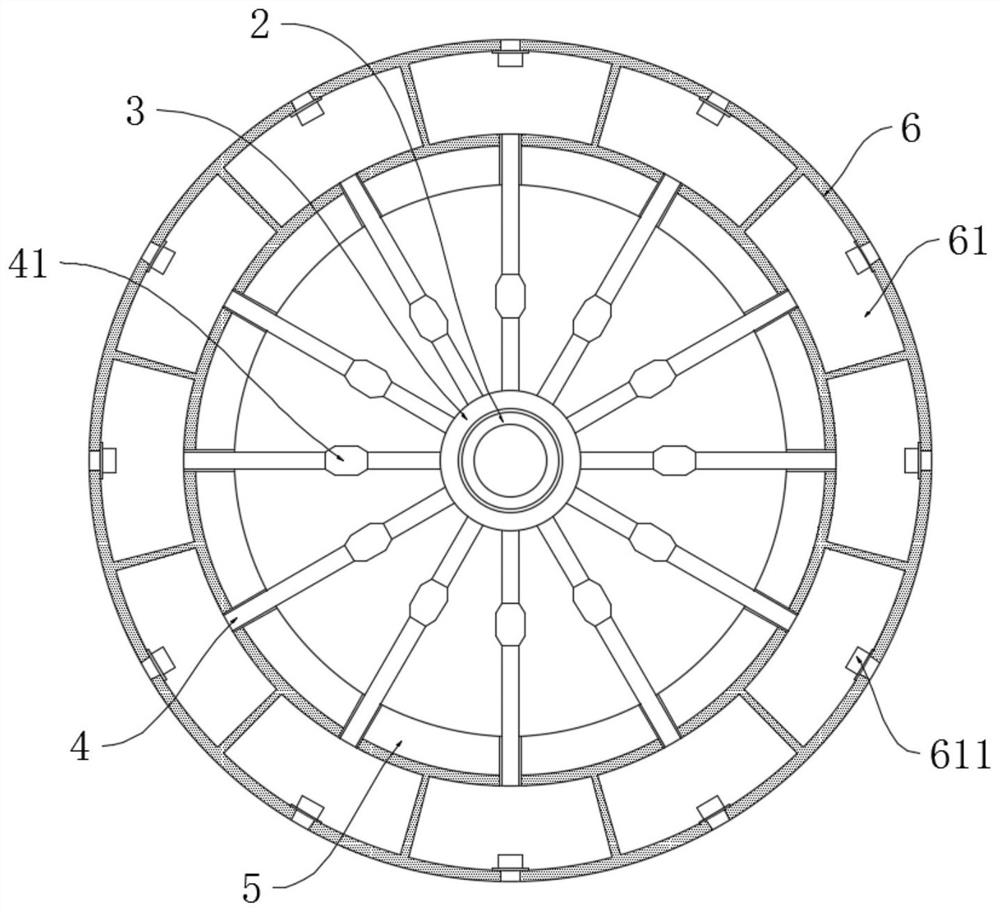

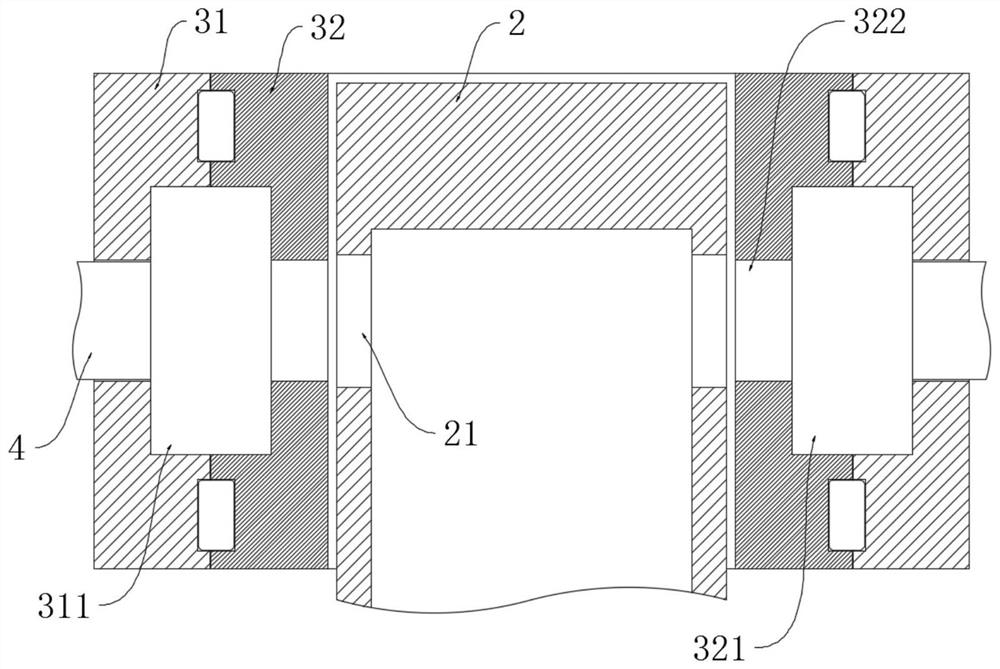

[0025] refer to Figure 1-4 , a dust-proof trolley for construction engineering, comprising a car body 1, a dust box 11 is installed on the lower bottom surface of the car body 1, a hollow shaft 2 is fixedly installed on the lower bottom surface of the dust box 11, and the two ends of the hollow shaft 2 are symmetrical Two ash guide bearings 3 are installed, and a plurality of support tubes 4 are installed in an annular equidistant manner on the outside of the ash guide bearing 3. A steel ring 5 is installed on the end of the plurality of support tubes 4 away from the ash guide bearing 3. The outer side of the steel ring 5 Air bag tire 6 is installed;

[0026] A plurality of airbag cavities 61 are provided in the airbag tire 6, and a one-way valve 611 is inserted on the wall of each airbag cavity 61 far away from the support tube 4, and a one-way valve 611 is inserted at the end of each support tube 4 away from the ash guide bearing 3. Pass through the steel ring 5 and insert...

Embodiment 2

[0033] refer to Figure 5 , a dust-proof trolley for construction engineering, which is basically consistent with Embodiment 1, the difference is that:

[0034] On the outer wall of the steel ring 5, a plurality of support partitions 51 are installed in a circular equidistant manner, and elastic airbags 7 are jointly installed between two adjacent support partitions 51, and each elastic airbag 7 is far away from the inner side of the support tube 4. A one-way pressure air bag mouth 71 is inserted on the wall of the bag;

[0035] A plurality of elastic airbags 7 are installed between the plurality of supporting partitions 51 of the steel ring 5 in a modular manner, so that the elastic airbags 7 can be disassembled more conveniently, and can be quickly replaced when damaged without affecting the work of the remaining elastic airbags 7 .

[0036] In this embodiment, the elastic airbag 7 sucks the dust into the elastic airbag 7 through the one-way pressure airbag mouth 71. When o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com