Three-dimensional transparent film packaging machine

A packaging machine and transparent film technology, applied in packaging, transportation and packaging, packaging/bundling items, etc., can solve problems such as noise and unsatisfactory mute effect, vibration and inertial shaking, and not beautiful corners, etc., to achieve no noise and mute effect Good, improve the packaging progress, the effect of stable and fixed equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

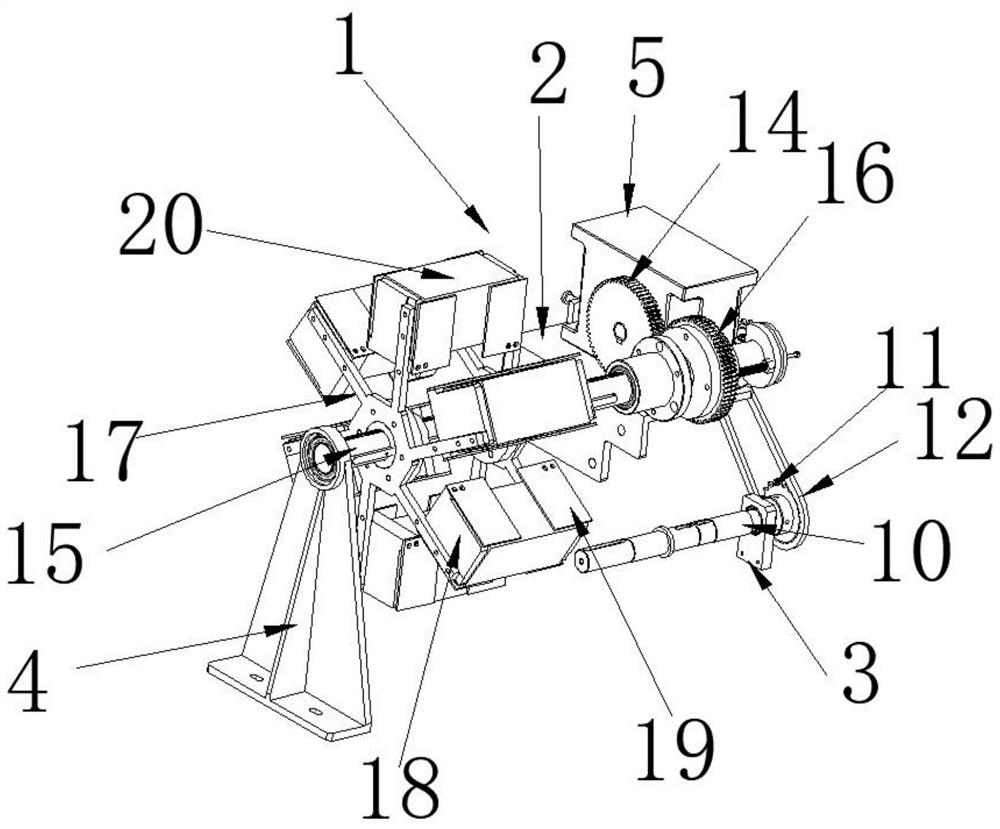

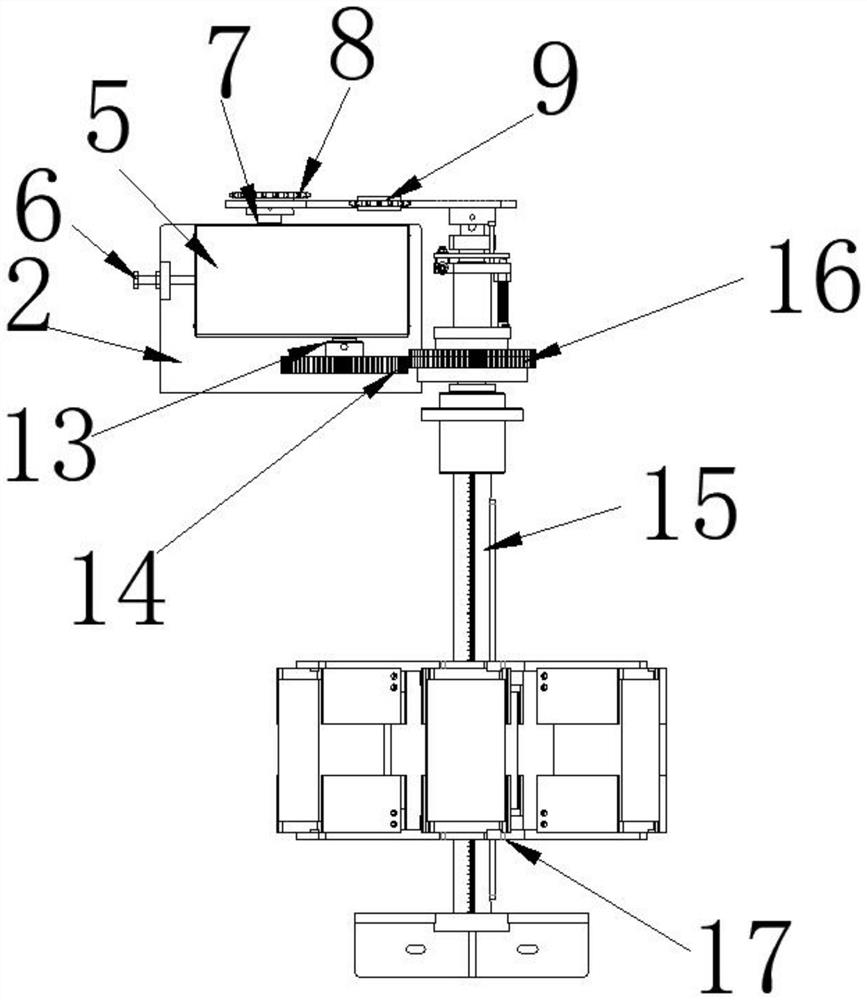

[0020] Such as Figure 1-2 As shown, the three-dimensional transparent film packaging machine according to the embodiment of the present invention includes a packaging machine body 1, and the packaging machine body 1 includes a support seat 2, a support seat 2 and a support seat 3 4, and the support seat 2 3 The top is provided with a mounting box 5, one side of the mounting box 5 is provided with a rotating shaft 7, and the rotating shaft 7 is sleeved with a rotating gear 8 and a rotating gear 2 positioned at one side of the rotating gear 8. 9. The inside of the support seat 2 3 is interspersed with a rotating shaft 2 10, and the rotating shaft 2 10 is sleeved with a rotating gear 3 11, and the rotating gear 3 11 and the rotating gear 1 8 are connected by a transmission chain 12, and the second rotating gear 9 is meshed with the transmission chain 12, and the installation box 5 is provided with a rotating shaft three 13 on the side away from the rotating shaft one 7, and the ...

Embodiment 2

[0023] Such as figure 1 , 2 As shown, one side of the installation box 5 is provided with a fixed rod 6 connected to the top end of the support seat 1 2 .

[0024] Such as figure 1 , 2 As shown, the first sextant mold claw 18 and the second sextant mold claw 19 are rectangular structures, and one of the sextant mold claw one 18 is composed of the second sextant mold claw 19 A product box 20 is arranged in the frame.

[0025] Such as figure 1 , 2 As shown, the frame formed by the first sextant mold claw 18 and the second sextant mold claw 19 is a cuboid structure.

[0026] Such as figure 1 , 2 As shown, the rotating gear four 14 and the rotating gear five 16 are gears with equal addendum circles and the same modulus, and the transmission ratio between the first rotating gear 8 and the fourth rotating gear 14 is 6:1.

[0027] Working principle: When in use, connect the rotating shaft 2 10 with the motor, and then make the rotating shaft 2 10 drive the rotating gear 3 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com