tank container

A tank container and tank body technology, which is applied in the direction of tank trucks, packaging, transportation and packaging, etc., can solve the problem of low space utilization rate, and achieve the effect of improving space utilization rate, increasing height, and increasing its own volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] It should be noted that the embodiments in the present application and the features of the embodiments may be combined with each other in the case of no conflict. The present invention will be described in detail below with reference to the accompanying drawings and in conjunction with the embodiments.

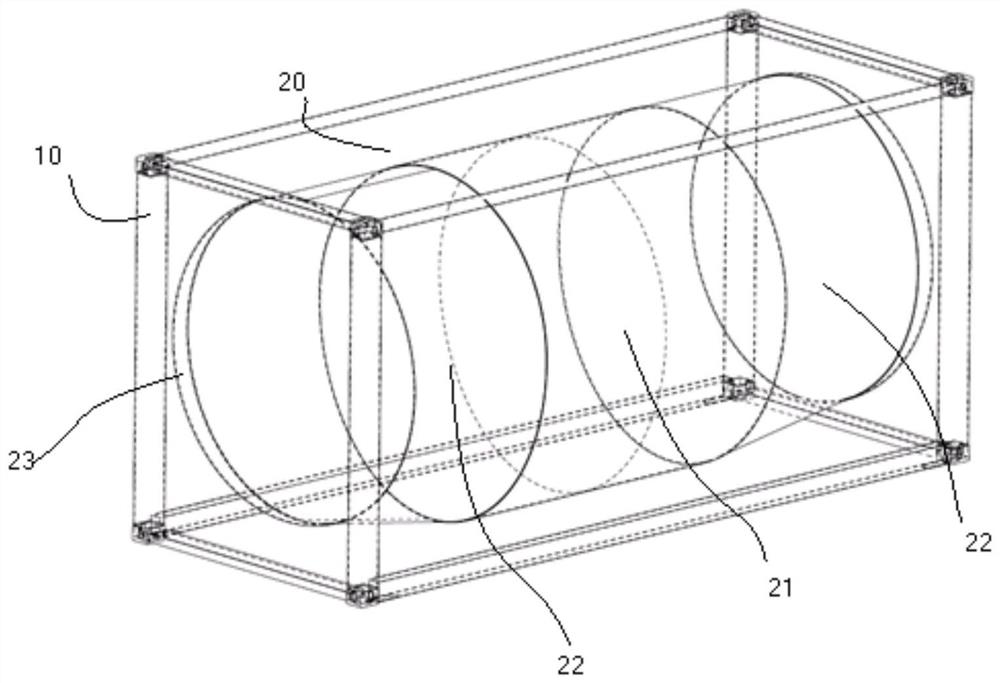

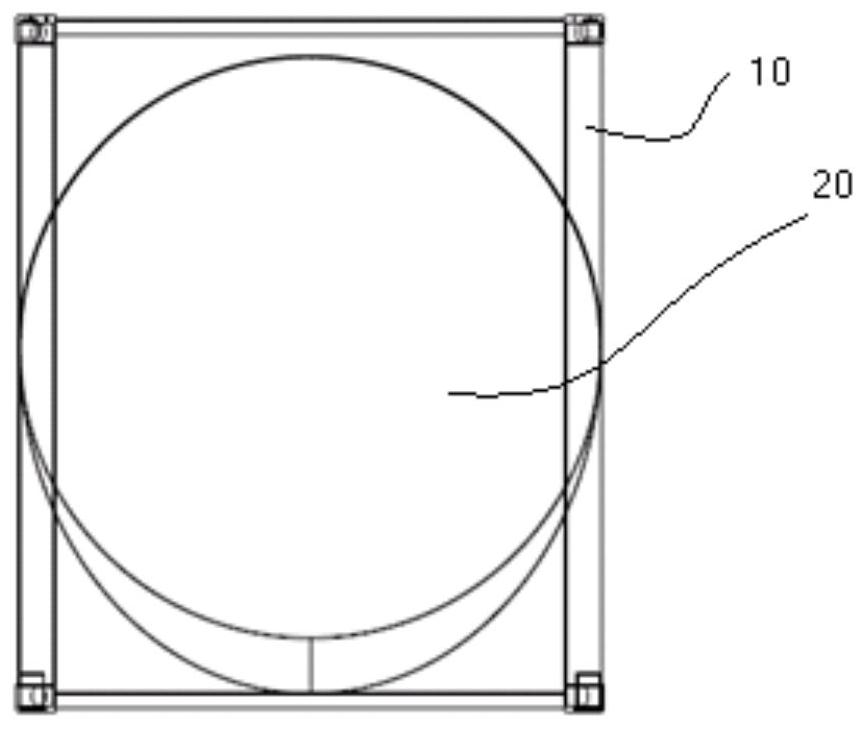

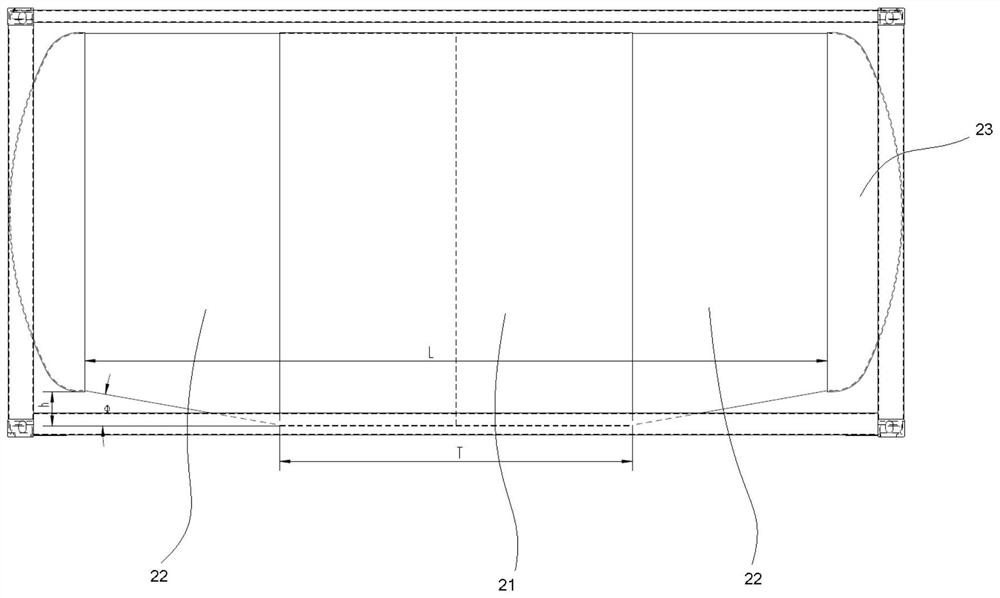

[0023] As described in the background art, the current tank container generally adopts a circular tank body, and the frame height dimension of the container product is larger than the width dimension. When the circular section makes full use of the width dimension, the height space cannot be fully utilized, and the inside of the tank is not fully utilized. There are inclined baffles and fluidized beds, which divide the tank into upper and lower cavities. The lower space is not used for loading goods, but only for the airflow passing through the space while forming an inclined surface for diversion. The upper space is the cargo space. There are three main problems with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com