A magnetic strip and magnetic block combination feeding device used in a magnetic soft screen door production line

A technology of feeding device and soft screen door, applied in thin material handling, object supply, loading/unloading, etc., can solve the problems of low production efficiency, time-consuming and labor-intensive, etc., and achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The embodiments described below by referring to the figures are exemplary only for explaining the present invention and should not be construed as limiting the present invention.

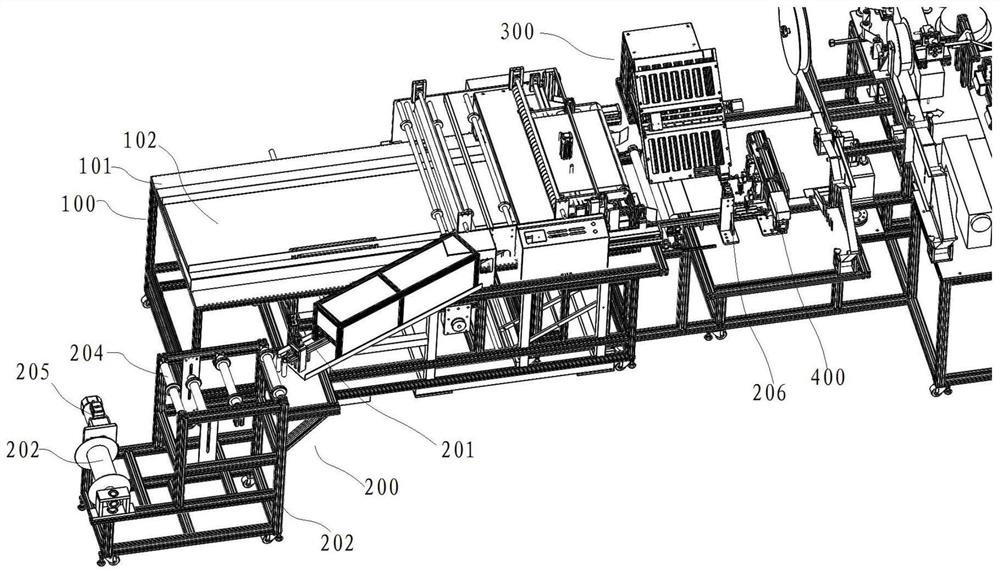

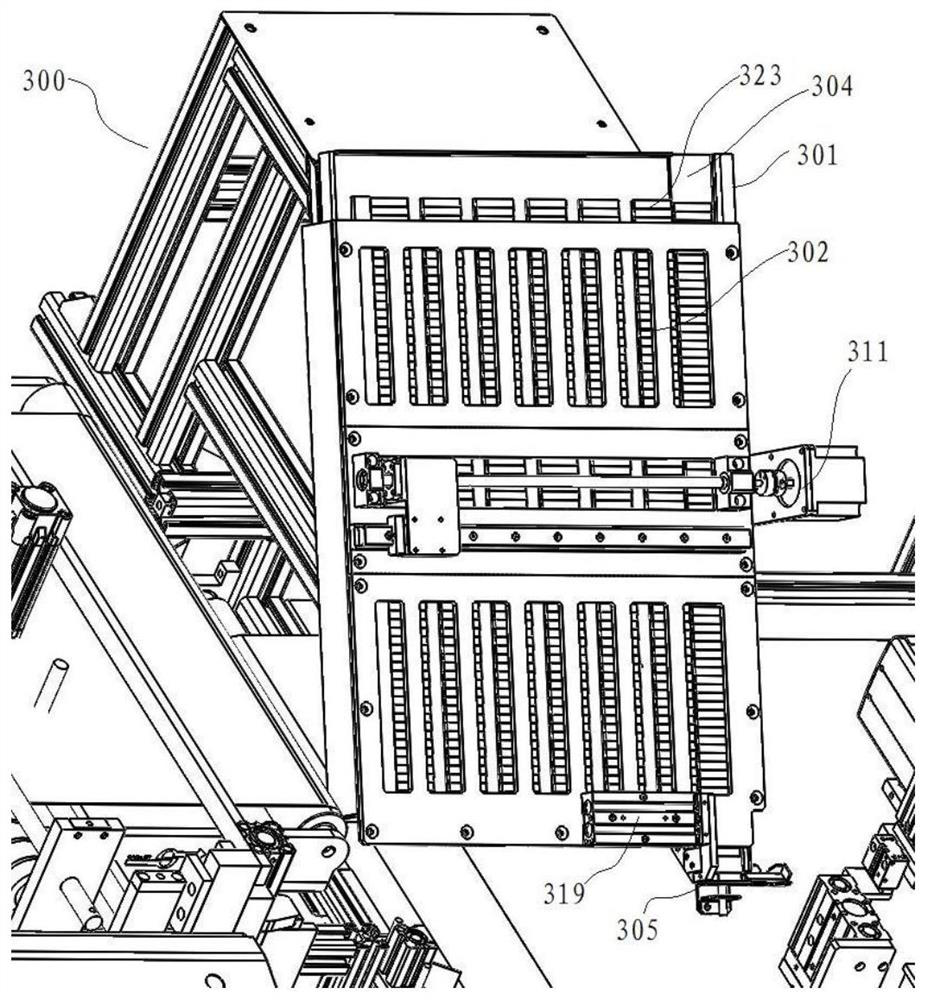

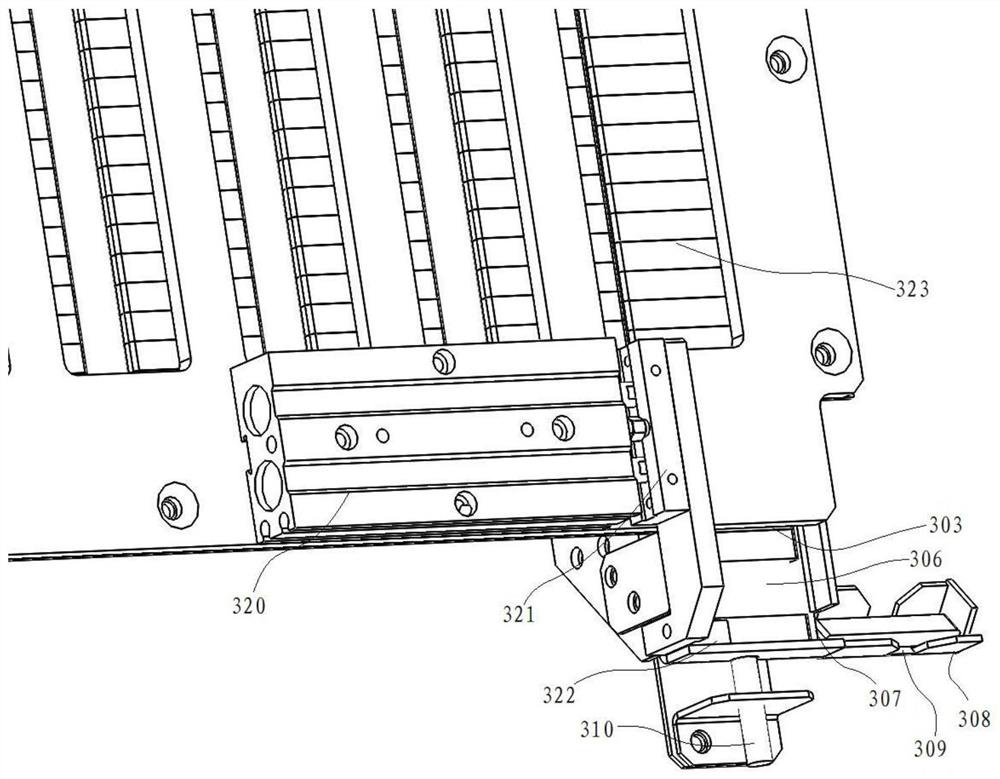

[0042] Such as Figure 1-5 As shown, the embodiment of the present invention provides a magnetic strip and magnetic block combination feeding device used on a magnetic soft screen door production line, including a mesh yarn sheet conveying unit 100, a magnetic strip feeding unit 200, and a magnetic block feeding unit. Unit 300 and combined unit 400, wherein:

[0043] The mesh yarn delivery unit 100 includes a mesh yarn delivery rack 101, and the mesh yarn sheet 102 is continuously transported in a horizontal posture on the mesh yarn delivery rack 101; then it reaches the end of the mesh yarn delivery rack 101 When the end is cut into a single piece of equal length, the conveying structure and cutting structure of the mesh yarn sheet 102 can refer to the fabric unwinding and cutting structure...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com