Centrifugal spinning frame

A spinning frame, centrifugal technology, applied in the spinning machine, continuous winding spinning machine, textile and papermaking, etc., can solve the problem of increasing the suction force, the function of the yarn sensor, and the optimization of the position of the suction tube Difficulties and other issues, to achieve the best effect of the position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Hereinafter, embodiments of the present invention will be described in detail with reference to the accompanying drawings.

[0024]

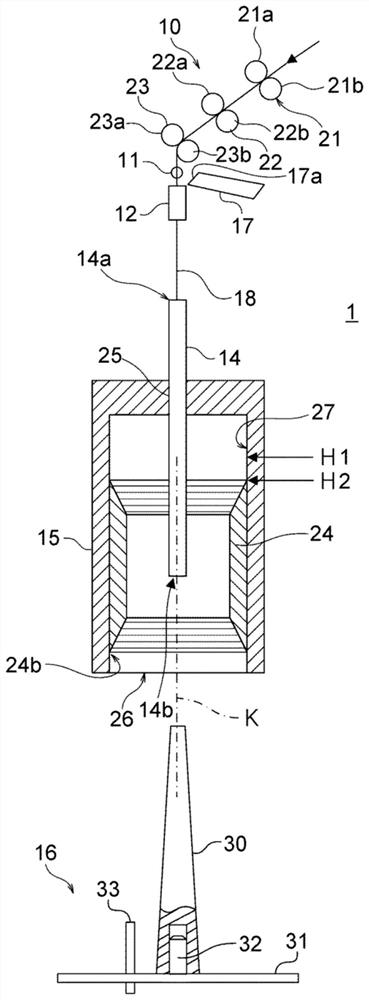

[0025] figure 1 It is a schematic diagram which shows the structural example of the centrifugal spinning frame which concerns on embodiment of this invention.

[0026] Furthermore, in figure 1 In the figure, the structure of each part of the centrifugal spinning frame is shown in a simplified manner, and the actual shape and size may be different.

[0027] like figure 1 As shown, the centrifugal spinning frame 1 includes a draft device 10 , a yarn sensor 11 , a pneumatic nozzle 17 , a yarn suction bobbin 12 , a yarn guide bobbin 14 , a tank 15 , and a bobbin support portion 16 . Further, these constituent elements constitute one spindle as one unit of spinning. The centrifugal spinning frame 1 includes a plurality of spindles, but the configuration of one of the spindles will be described here.

[0028] (Drafting device)

[0029] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com