Lithium-ion battery for forced internal short-circuit test and preparation method thereof

A lithium electronic battery and a technology for testing, which are applied in the field of lithium electronic battery for compulsory internal short test and its preparation, can solve the problems of difficult to find the location, volatile electrolyte leakage and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The specific embodiments of the present invention will be described below mainly in conjunction with the accompanying drawings.

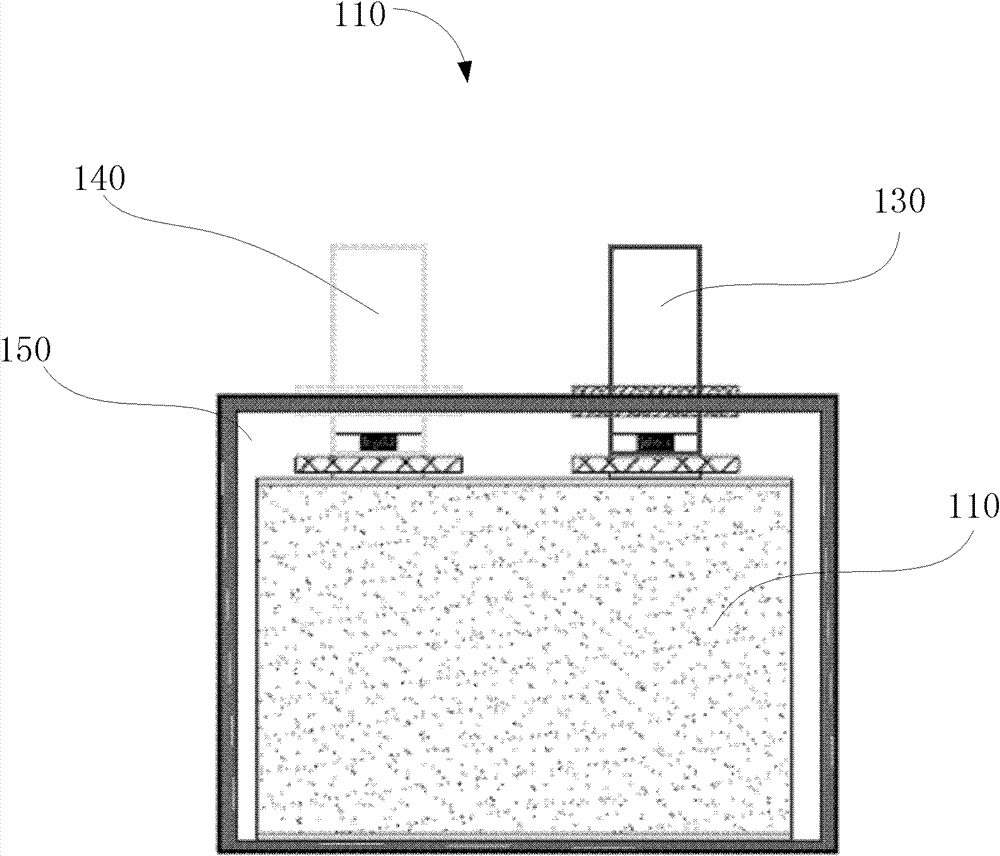

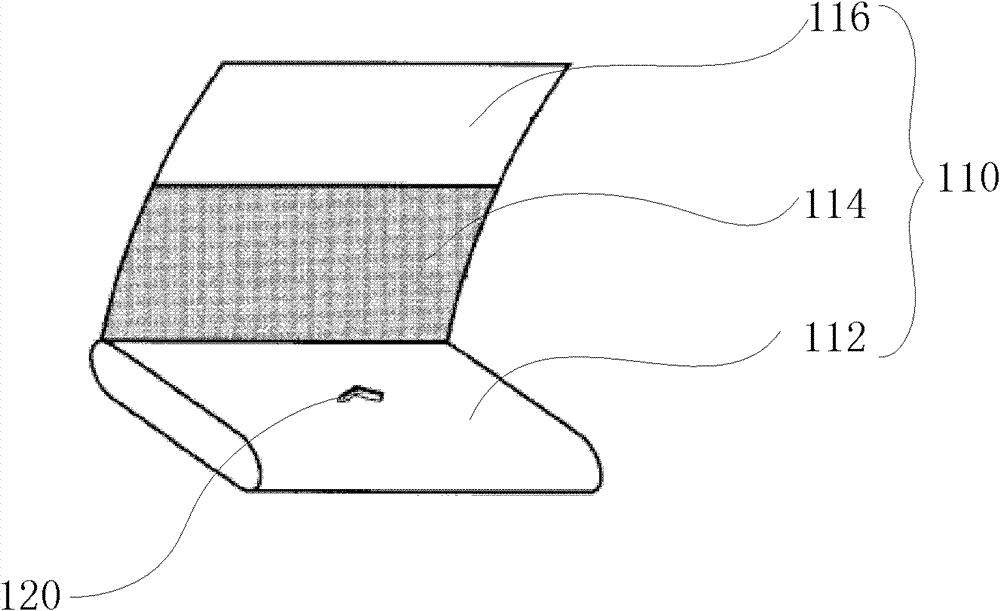

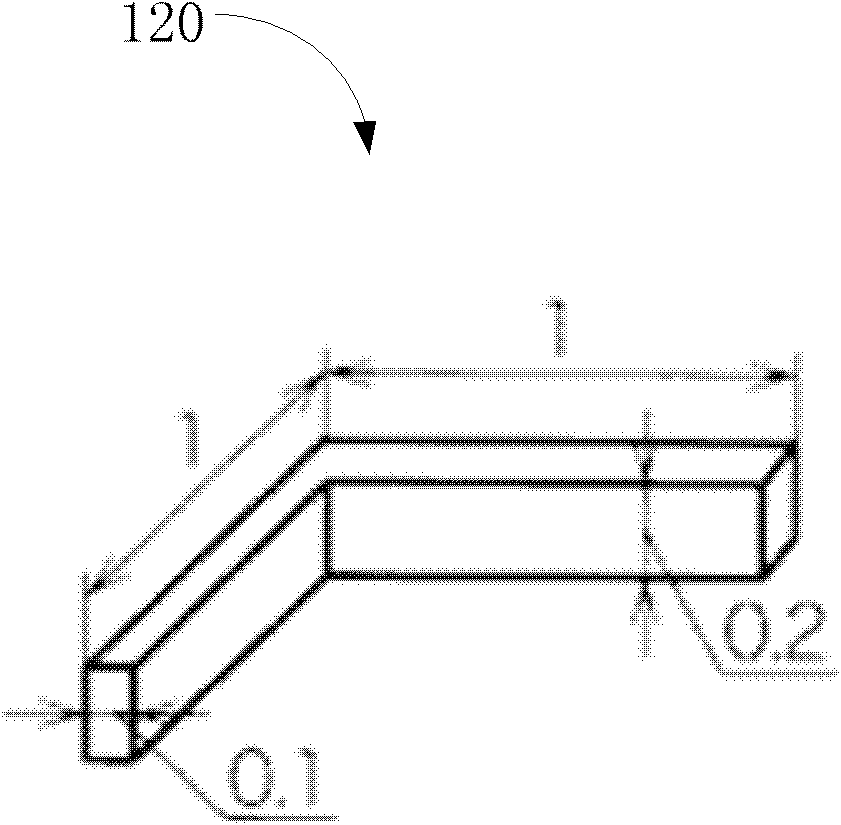

[0036] see figure 1 and figure 2 The lithium-ion battery 100 for the forced internal short-circuit test of the first embodiment includes a lithium-ion battery core 110 , a short-circuit metal piece 120 , a positive electrode tab 130 , a negative electrode tab 140 and a sealing packaging film 150 .

[0037] The lithium electronic battery core 110 is a square lithium electronic battery core, which has been removed from the outer package and fully charged. The lithium electronic battery core 110 includes a separator 112 , a positive electrode 114 , a negative electrode (not shown) and an aluminum foil 116 . The separator 112 is spaced between the positive electrode 114 and the negative electrode to prevent the lithium-ion battery core 110 from short circuiting. The positive electrode is formed by coating the aluminum foil 116 with a conducti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com