Right-angle bus bar for power distribution and production method and equipment thereof

A technology for producing equipment and bus bars, applied in other manufacturing equipment/tools, manufacturing tools, etc., can solve the problems of low production efficiency and welding accuracy, uneven cutting length of bus bars, damaged bus bars, etc., so as to improve the qualified rate of products , Easy to pack, not easy to mess up

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

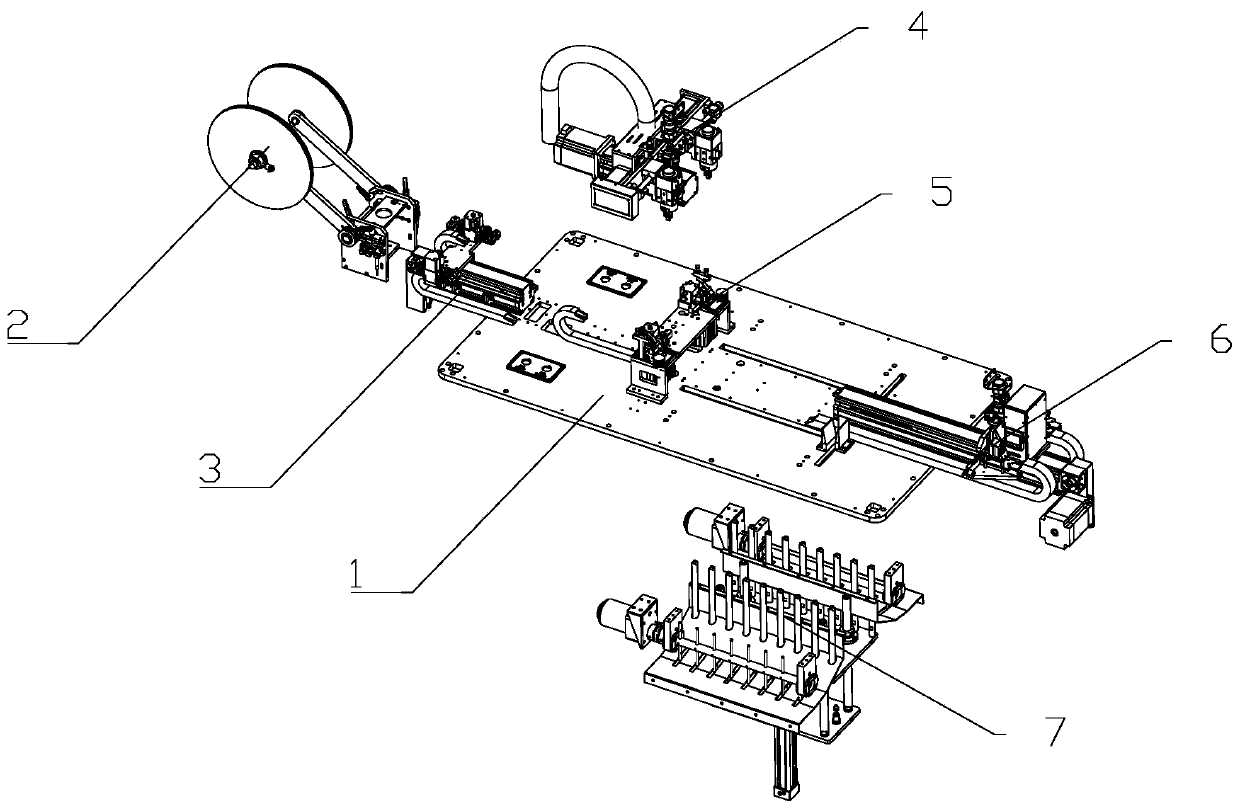

[0028] Such as figure 1 As shown, a right-angle bus bar production equipment for power distribution, including a frame 1 and a strip assembly 2 installed on the frame 1, a feeding mechanism 3, a retrieving mechanism 4, a material cutting mechanism 5, a welding mechanism 6 and The blanking mechanism 7; along the workpiece feeding direction. The strip assembly 2, the feeding mechanism 3, the cutting mechanism 5, the blanking mechanism 7 and the welding mechanism 6 are successively connected, and the blanking mechanism 7 is located under the frame; The production equipment for a right-angled bus bar for power distribution described above has two processing routes arranged side by side and carried out synchronously.

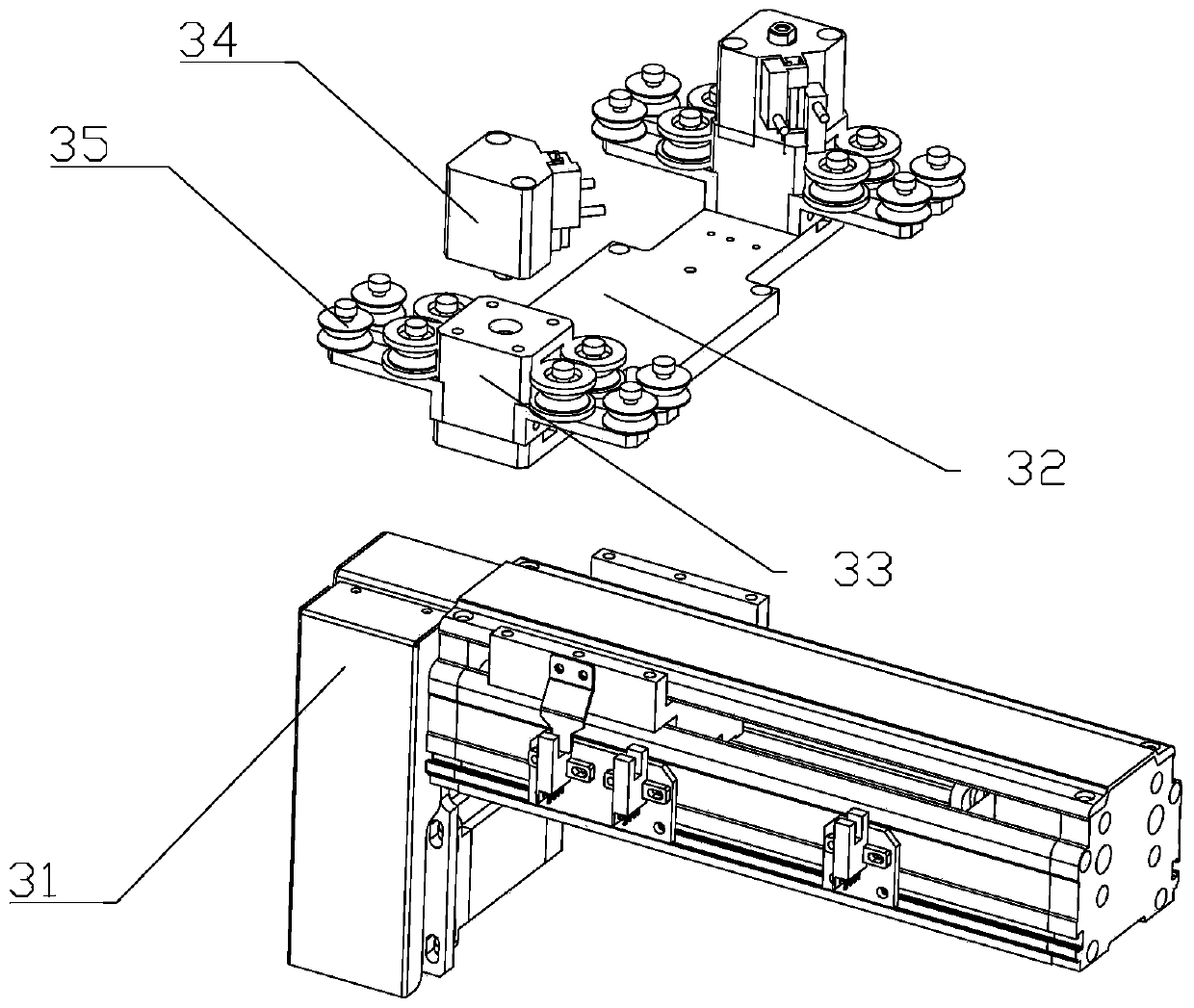

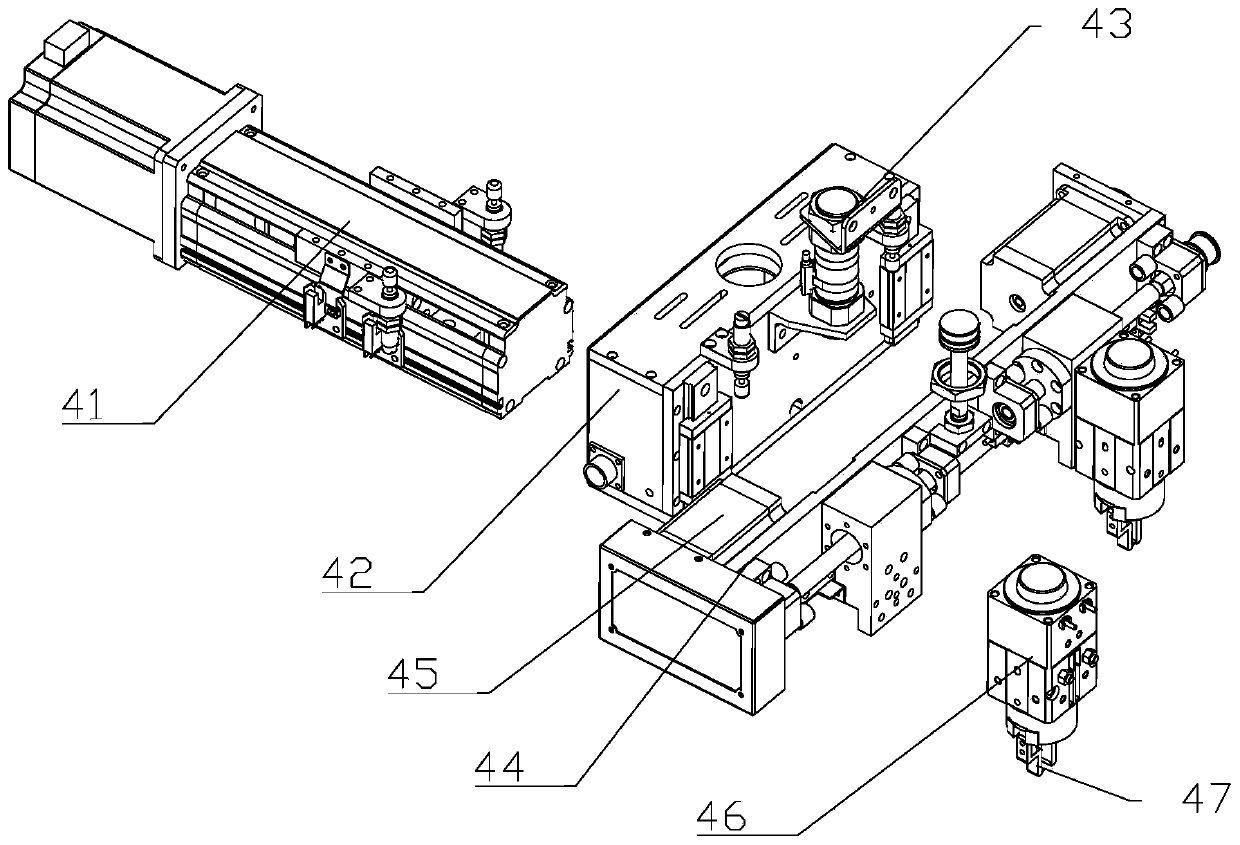

[0029] The strip assembly 2 is used to wind the coil of the bus bar, the feeding mechanism 3 is used to drive the feeding of the bus bar and straighten it; the cutting mechanism 5 is used to cut the bus bar, and the feeding mechanism 4 is used to cut the bus bar. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com