Automatic instrument device

An instrument and inner surface technology, applied in the field of automated instrumentation devices, can solve problems such as damage and accidental impact, and achieve the effects of convenient operation, improving service life and preventing damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

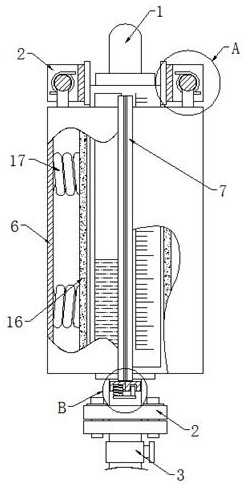

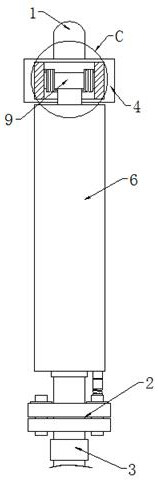

[0026] Example 1 as Figure 1-2 As shown, this automatic instrument device includes a liquid level gauge 1, a flange 2 and a drain valve 3, the flange 2 is located at the bottom of the liquid level gauge 1, the drain valve 3 is located at the lower end of the flange 2, and the upper end of the liquid level gauge 1 Both sides are fixed with connecting plates 4, and the other ends of the two connecting plates 4 are fixed with U-shaped plates 5, and both sides of the liquid level gauge 1 and below the two U-shaped plates 5 are equipped with U-shaped protective plates. Plate 6, the U-shaped protective plate 6 is set to effectively protect the liquid level gauge 1, the U-shaped protective plate 6 is wrapped and arranged on the outside of the liquid level gauge 1, and the front sides of the two U-shaped protective plates 6 are fixed with a vertical plate 7 , the bottoms of the two vertical plates 7 are fixedly provided with connecting blocks 8, the insides of the two connecting bloc...

Embodiment 2

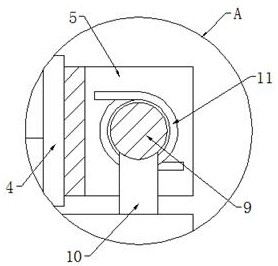

[0027] Embodiment 2 is on the basis of embodiment 1 such as image 3 and Figure 5 As shown, its elastic recovery mechanism includes a rotating rod 9, the two ends of the rotating rod 9 are fixedly connected with the two ends of the inner surface of the U-shaped plate 5 respectively, the bottom of the rotating rod 9 is fixedly provided with a support rod 10, and the bottom of the support rod 10 Fixedly connected with the top of the U-shaped protective plate 6, the two ends of the rotating rod 9 are sleeved with a torsion spring 11, and the two ends of the torsion spring 11 are fixedly connected with the inner surface of the U-shaped plate 5 and the support rod 10 respectively.

Embodiment 3

[0028] Embodiment 3 is such as on the basis of embodiment 1 Figure 4 As shown, its connection mechanism includes a pull plate 12 and an insertion rod 13, the bottom of the left connecting block 8 is provided with a mounting groove, the bottom of the right connecting block 8 is provided with a slot, and the bottom of the mounting groove is fixed with a telescopic rod 14 and the first spring 15, the other end of the telescopic rod 14 and the first spring 15 is fixedly connected with the top left side of the pull plate 12, the bottom of the insertion rod 13 is fixedly connected with the top right side of the pull plate 12, and the top is connected with the slot Plugging, the first spring 15 is socketed with the telescopic rod 14, and the socket is connected with the plugging rod to connect the two U-shaped protective plates 6 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com