Load determination method for test hinge points of pressing frame of hydraulic support based on virtual prototype technology

A virtual prototype technology and hydraulic support technology are applied in the field of determining the hinge point load of the hydraulic support press frame test, which can solve problems such as lack of in-depth research, and achieve the effect of avoiding manpower and material resources and shortening the product design cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following is attached Figure 1-6 Shown, the present invention is further described.

[0024] The method for determining the hinge point load of hydraulic support press frame test based on virtual prototype technology includes the following steps:

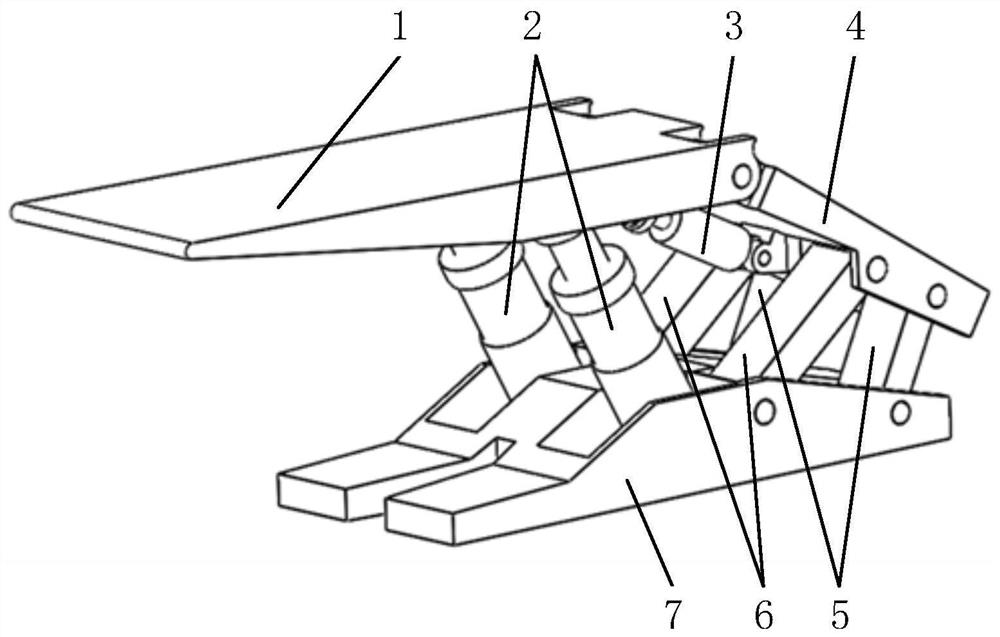

[0025] S1, through the general assembly drawing of a type of hydraulic support, extract the positional relationship between the hinge points and the exact coordinate spacing size, and establish a simplified three-dimensional model diagram of the type of hydraulic support with roof protection, as shown in figure 1 shown. It consists of a top beam 1, a column 2, a balance jack 3, a cover beam 4, a rear link 5, a front link 6, and a base 7. Top beam 1 is hinged to cover beam 2, one end of top beam 1 is hinged to column 2, one end of top beam 1 is hinged to balance jack 3, the other end of cover beam 4 is hinged to balance jack 3, and one end of cover beam 4 is hinged to rear connecting rod 5. Shield beam 4 is hinged with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com