Piston type pipette capable of improving pipetting precision

A technology of piston type and pipette gun, which is applied in measuring tubes/pipettes, laboratory containers, chemical instruments and methods, etc. It can solve the problems of increasing processing accuracy, increasing manufacturing difficulty and cost, and processing difficulty. , to achieve the effect of improving pipetting accuracy, reducing processing difficulty and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

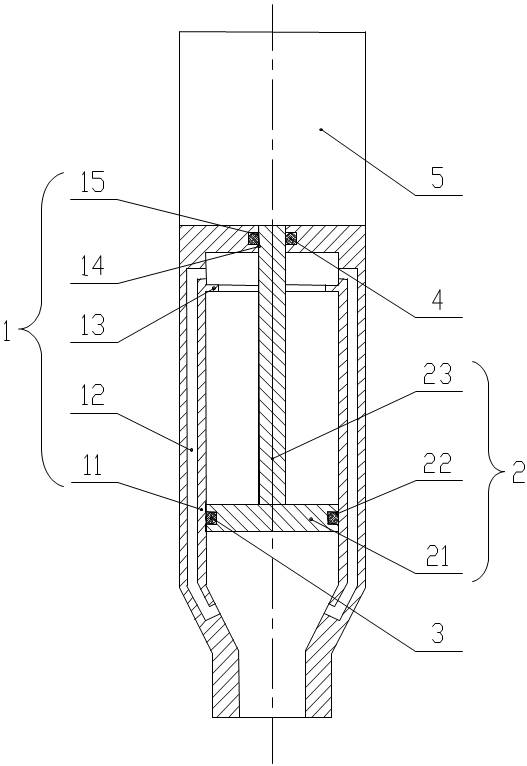

[0021] The following will combine figure 1 The present invention is described in detail, and the exemplary embodiments and descriptions of the present invention are used to explain the present invention, but not to limit the present invention.

[0022] refer to figure 1 , a piston-type pipette gun for improving pipetting accuracy, comprising a gun body 1, a piston 2, a piston seal ring 3, a gun body seal ring 4, and a piston moving device 5, and the gun body 1 includes a gun body 11, a ventilation groove 12, Top hole 14, body of a gun groove 15, piston 2 comprises piston ring 21, piston groove 22, piston rod 23, ventilating groove 12 is arranged in the body of a gun 11, and ventilating groove 12 upper end holes are located at the top of body of a gun 11 sidewalls, The lower end hole is located at the bottom of the body of the gun 11 side walls, the top hole 14 and the groove 15 of the body of the gun are located at the top wall of the body of the gun 11, the sealing ring 4 of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com