Cover plate testing machine

A testing machine and cover plate technology, applied in the field of testing machines, can solve the problems of increased cover cost, low testing efficiency, cumbersome procedures, etc., and achieve the effects of reducing work intensity, high testing efficiency, and accurate testing results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

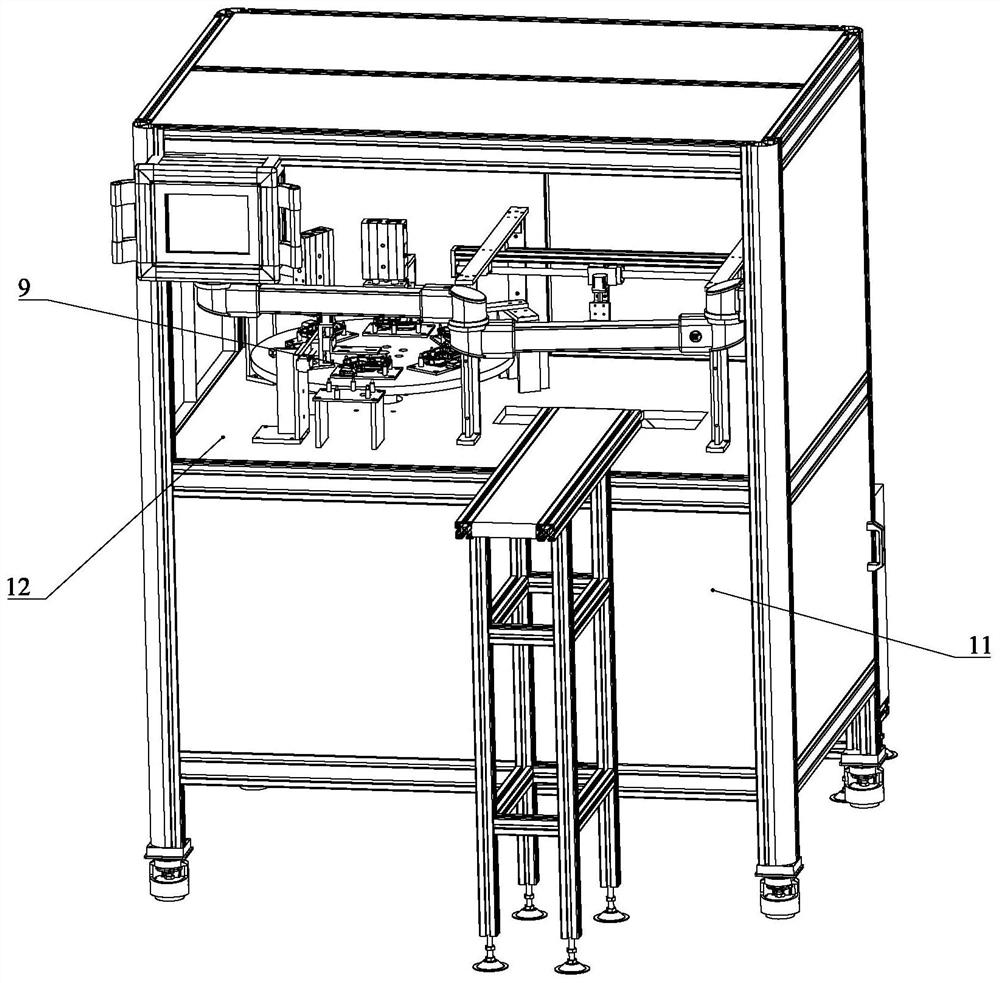

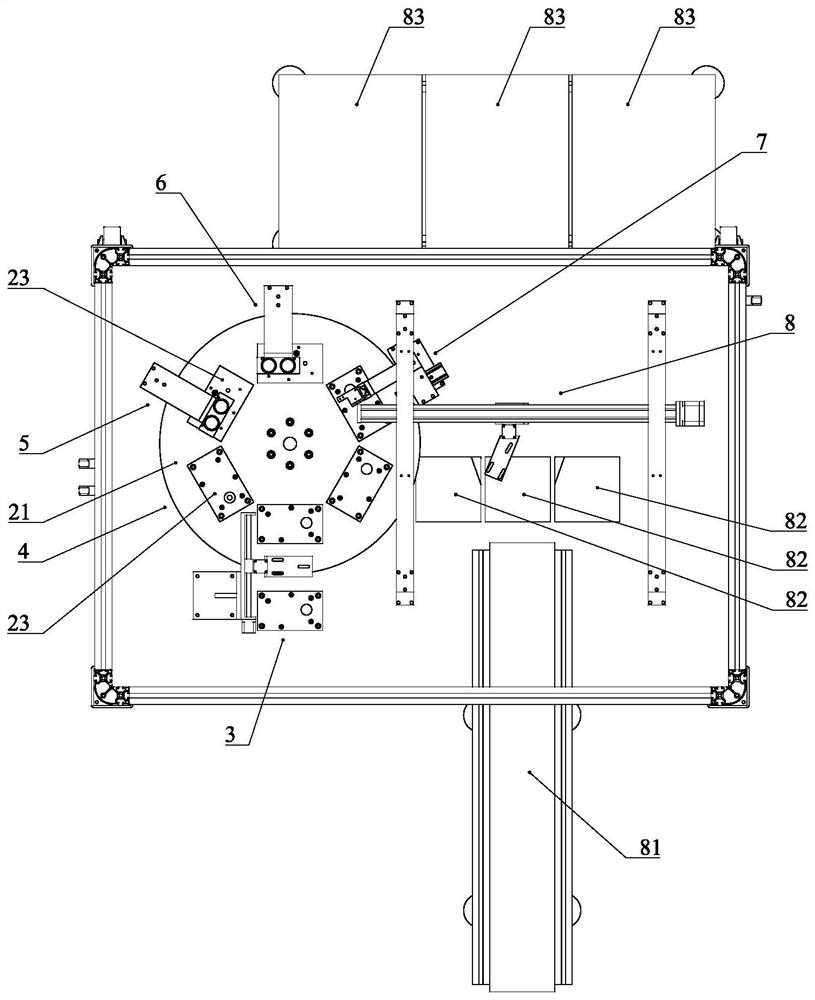

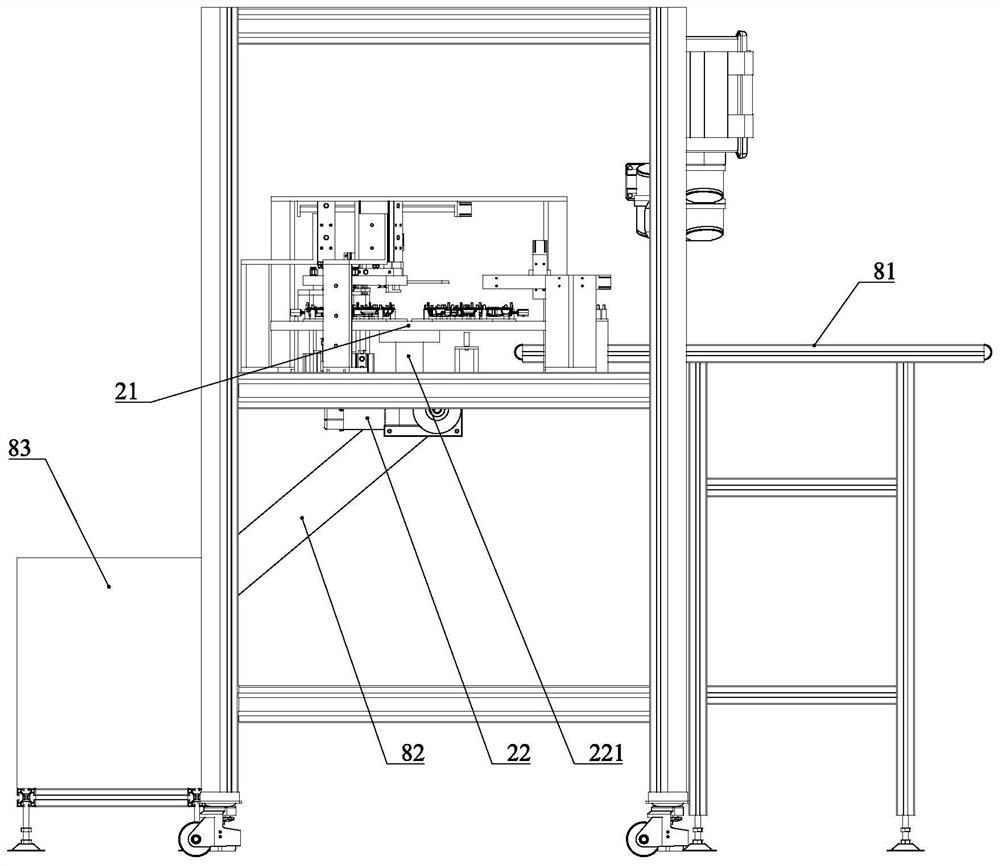

[0047] Below in conjunction with accompanying drawing, the present invention will be further described with specific embodiment, see figure 1 -17:

[0048] A cover testing machine, including a cabinet and a rotary device;

[0049] The cabinet includes a cabinet body 11 and a workbench 12 arranged on the cabinet body 11. On the workbench 12, a feeding station 3, a color mark detection station 4, an air tightness detection station 5, and a ventilation station are distributed in the circumferential direction. Sex detection station 6, conductive high voltage detection station 7 and blanking station 8, and are equipped with feeding device, color code detection device, air tightness detection device, gas permeability detection device, conductive high voltage detection device and blanking station device;

[0050] The color code detection device detects whether a filter screen 92 is installed on the cover plate 9 to be tested, the air tightness detection device detects the sealing p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com