A corrugated cardboard forming conveying system

A conveying system, corrugated board technology, applied in the direction of machining/deformation, etc., can solve the problem of inconvenient adjustment of corrugated board thickness, and achieve the effect of convenient adjustment and accurate gap control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

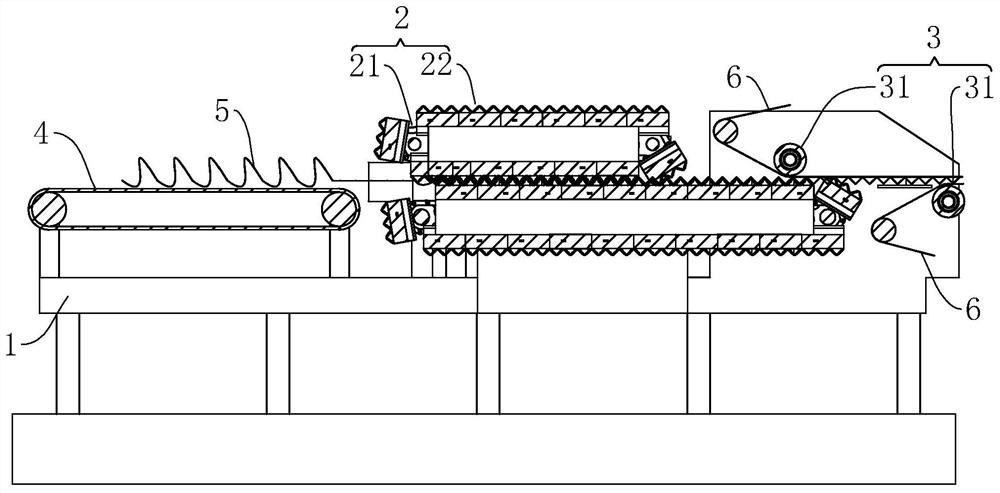

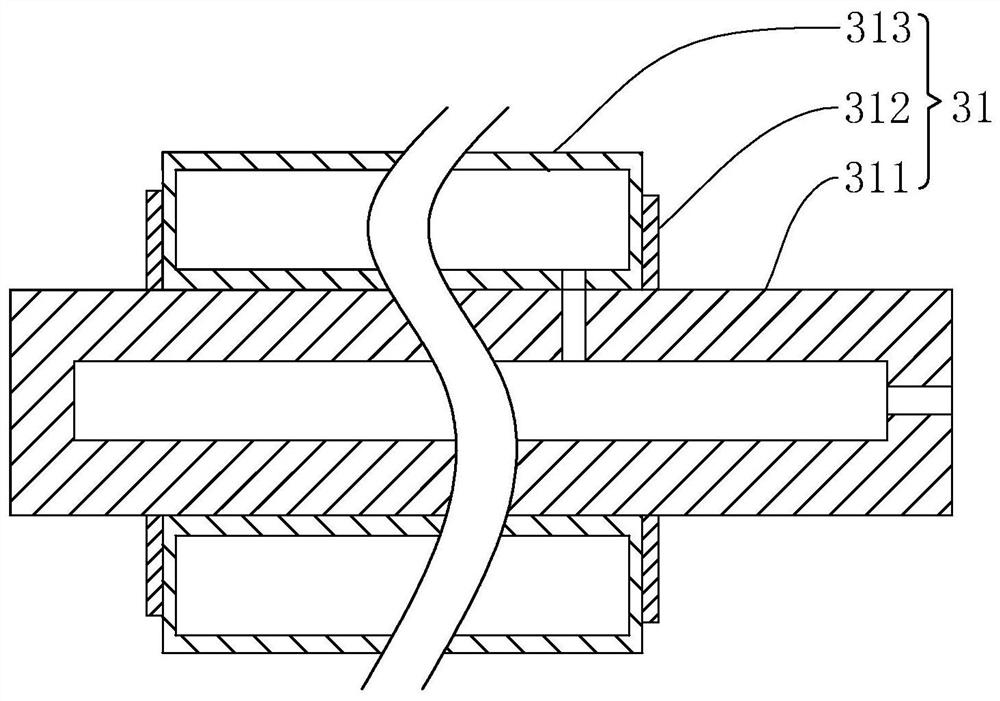

[0034] The following is attached Figure 1-6 The application is described in further detail.

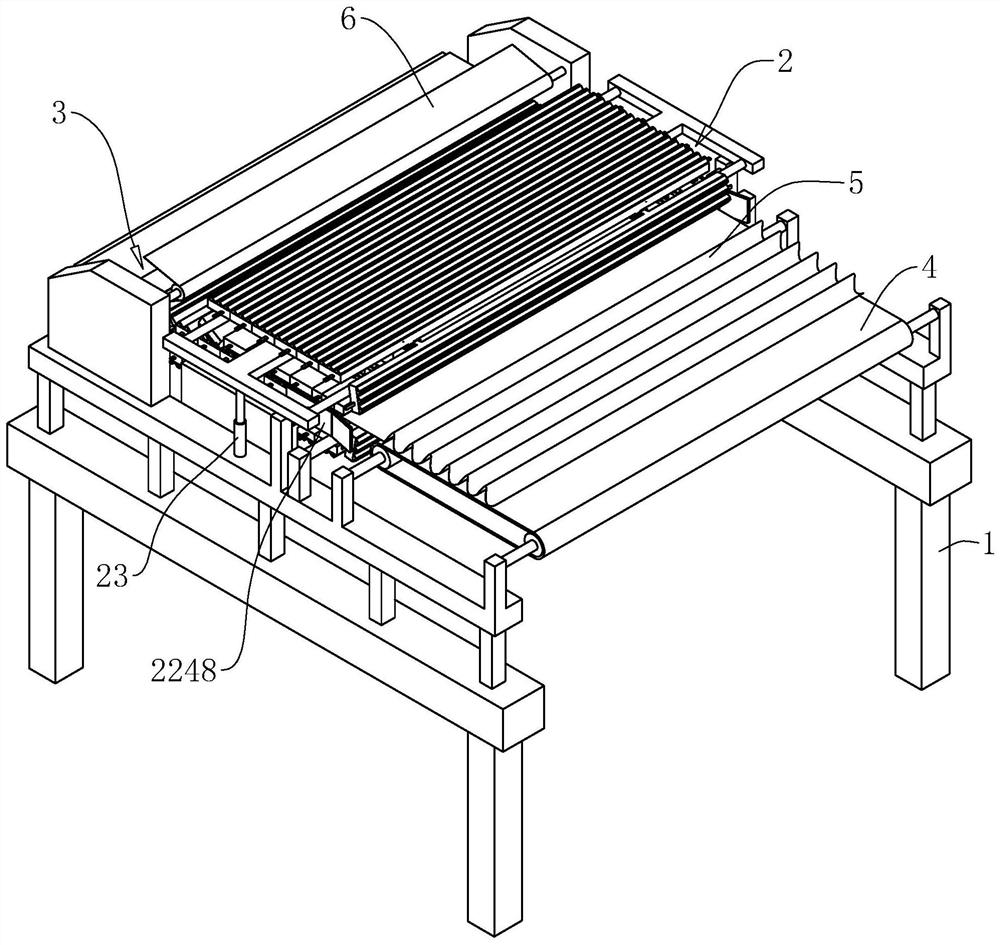

[0035] The embodiment of this application discloses a corrugated cardboard forming and conveying system, refer to figure 1 , including frame 1, frame 1 is provided with forming device and paper sticking device 3, one end of forming device is used to enter base paper 5, and a conveyor belt 4 is provided on the front side of one end of forming device entering base paper 5, conveyor belt 4 It is used to convey the base paper 5. After the base paper 5 enters the forming device, the base paper 5 is folded into a corrugated shape, and then flows out from the other end of the forming device, and the sticking device 3 is located at the end of the forming device. The sticking device 3 is used for conveying The two face papers 6 of the corrugated cardboard are respectively pasted on both sides of the base paper 5 during the delivery process, thereby forming a corrugated cardboard.

[0036] r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com