AGV capable of climbing

A technology of trolleys and ejectors, which is applied to conveyors, storage devices, mechanical conveyors, etc., can solve the problems of warehouse operation paralysis, high cost, and poor warehouse operation, and achieve a high degree of automation and high transportation efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

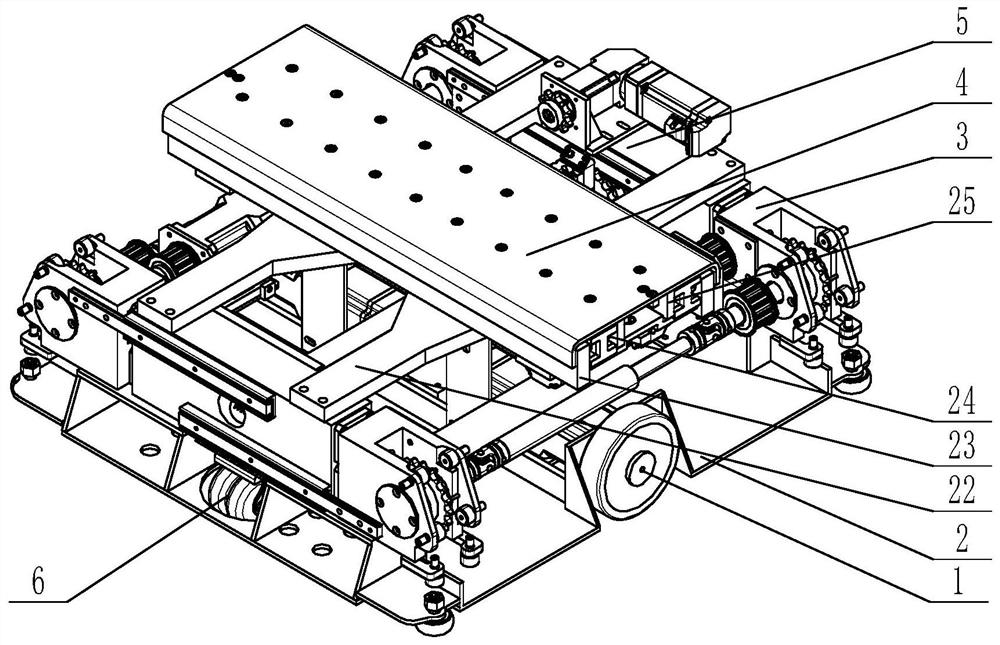

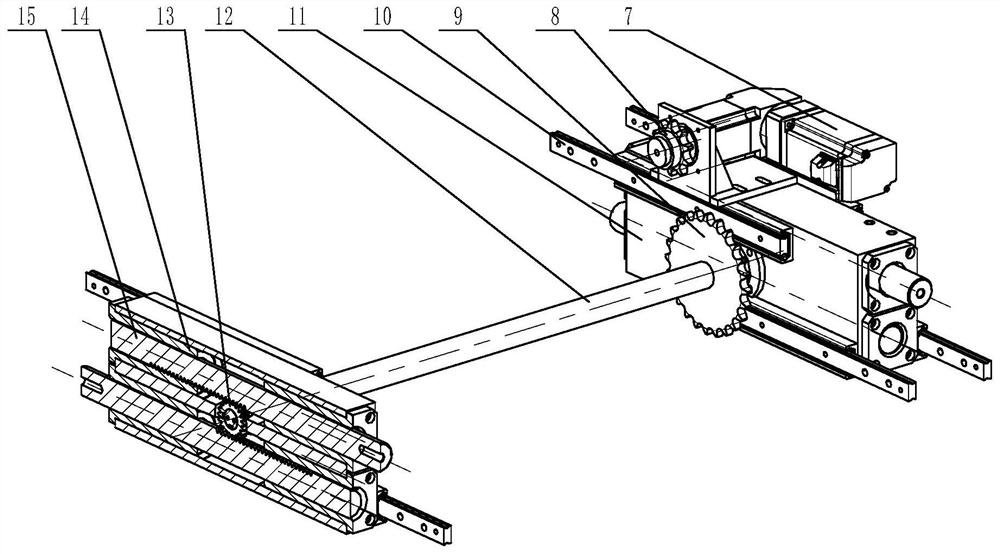

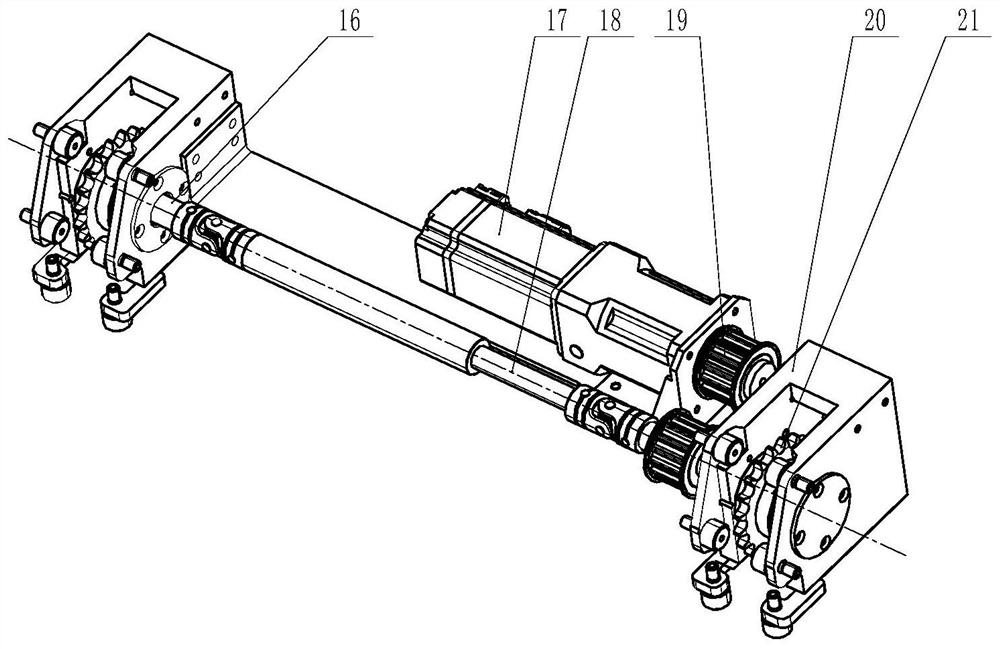

[0025] This embodiment provides a climbing AGV trolley, including a walking device 1, a base 2, a climbing device 3, a picking device 4, a climbing and ejecting device 5, a universal caster 6, a climbing and ejecting motor 7, Climbing driving sprocket 8, climbing driven sprocket 9, guide rail 10, guide seat 11, climbing ejection drive shaft 12, climbing ejection gear 13, guide sleeve 14, cylindrical rack 15, climbing drive shaft 16. Climbing motor 17, cardan shaft 18, synchronous pulley 19, climbing sprocket seat 20, climbing sprocket 21;

[0026] Specifically, such as figure 1 , The climbing AGV trolley provided in this embodiment is composed of a walking device 1 , a base 2 , a climbing device 3 , a picking device 4 , a climbing and ejecting device 5 , and swivel casters 6 .

[0027] Such as image 3 , Climbing device 3 comprises climbing transmission shaft 16, climbing motor 17, cardan shaft 18, synchronous pulley 19, climbing sprocket seat 20, climbing sprocket 21.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com