Foundation pit graded depressurization method

A technology of graded depressurization and foundation pit, applied in the direction of infrastructure engineering, construction, etc., can solve the problems of leakage, poor water head under pressure in the seventh layer, weak excavation construction of the foundation pit enclosure, etc., to reduce the water head. Poor, construction safety assurance, the effect of increasing the safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

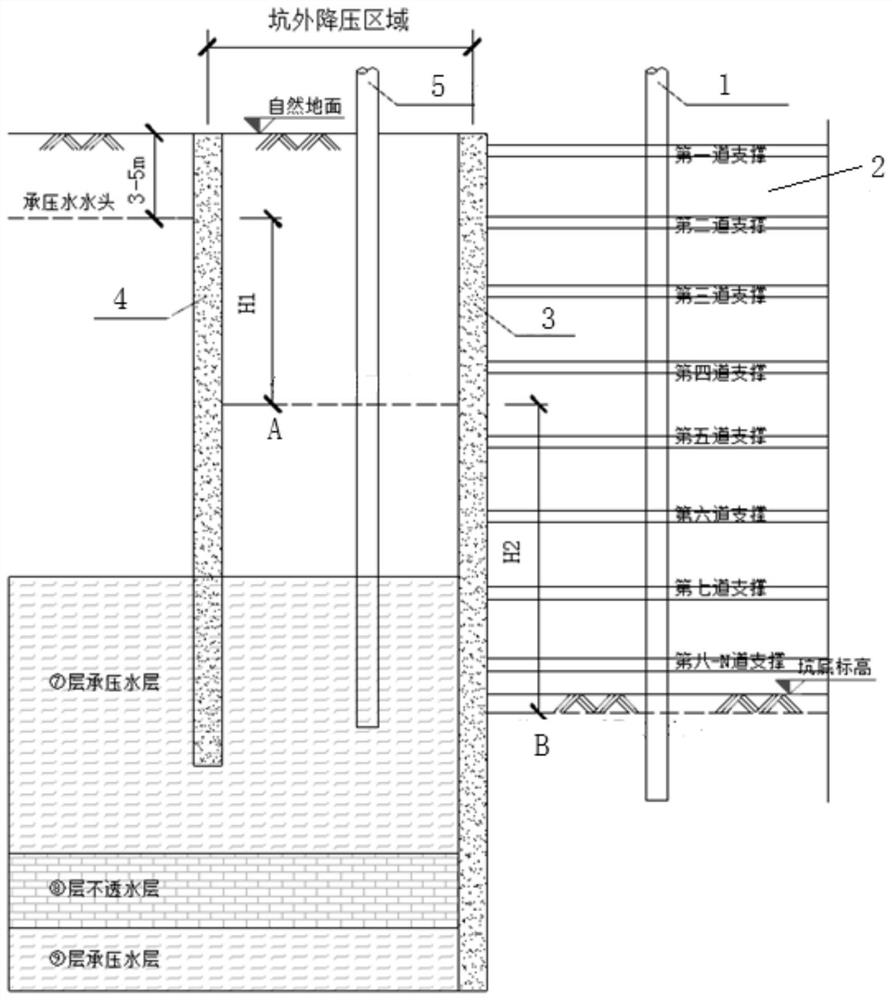

[0026] Such as figure 1 As shown, the present invention provides a step-by-step depressurization method for foundation pits, comprising:

[0027] Step S1, setting the pressure-reducing well 1 in the pit in the area 2 to be excavated;

[0028] Step S2, setting a ground wall 3 outside the area to be excavated 2, wherein the ground wall is inserted into the ninth confined water layer;

[0029] Step S3, setting a water-stop curtain 4 outside the ground wall 3, wherein the water-stop curtain is inserted into the seventh confined water layer;

[0030] Step S4, setting a decompression well outside the pit between the ground wall 3 and the water-stop curtain 4;

[0031] Step S5, by opening the decompression well 1 inside the pit and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com