Loader-digger provided with cable moving device

A technology for backhoe loaders and mobile devices, which is applied to earth movers/shovels, cleaning methods using tools, and arrangement of take-up reels/photosensitive drums, etc. Superior problem, to avoid the effect of cable cross and scattered

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

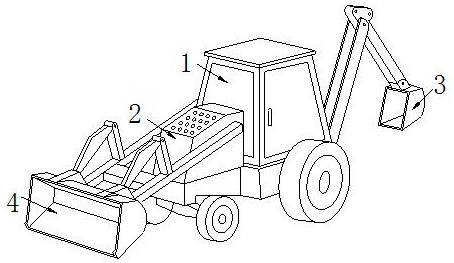

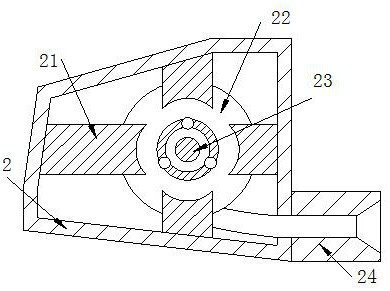

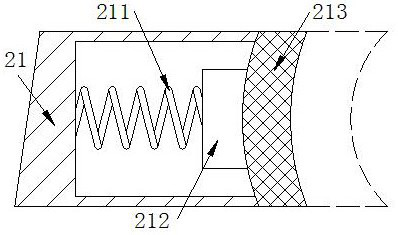

[0029] The invention provides a backhoe loader equipped with a cable moving device, the structure of which includes a console 1, a power assembly 2, an excavation end 3, and a loading end 4, and the power assembly 2 is connected to the front side of the console 1 by welding , the digging end 3 and the loading end 4 are respectively installed at the front and rear ends of the console 1, the power assembly 2 includes a positioner 21, a cable moving device 22, a winding shaft 23, and a protective cylinder 24, and one end of the positioner 21 It is connected to the inner wall of the power assembly 2 by welding, and the cable moving device 22 is connected to the inside of the power assembly 2 through movable engagement, and the outer surface of the cable moving device 22 is closely attached to the other end of the positioner 21, and the winding shaft 23 is connected to the other end of the positioner 21. The cable moving device 22 is located on the same axis. The left end of the pro...

Embodiment 2

[0035] The invention provides a backhoe loader equipped with a cable moving device, the structure of which includes a console 1, a power assembly 2, an excavation end 3, and a loading end 4, and the power assembly 2 is connected to the front side of the console 1 by welding , the digging end 3 and the loading end 4 are respectively installed at the front and rear ends of the console 1, the power assembly 2 includes a positioner 21, a cable moving device 22, a winding shaft 23, and a protective cylinder 24, and one end of the positioner 21 It is connected to the inner wall of the power assembly 2 by welding, and the cable moving device 22 is connected to the inside of the power assembly 2 through movable engagement, and the outer surface of the cable moving device 22 is closely attached to the other end of the positioner 21, and the winding shaft 23 is connected to the other end of the positioner 21. The cable moving device 22 is located on the same axis. The left end of the prote...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com