Gasket for improving resonance of vertical equipment

A technology of vertical equipment and gaskets, which is applied in the direction of mechanical equipment, leaf springs, engine frames, etc., can solve the problems of restricting the construction and operation of power plants, and the time-consuming work, so as to reduce the resonance amplitude and increase the damping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

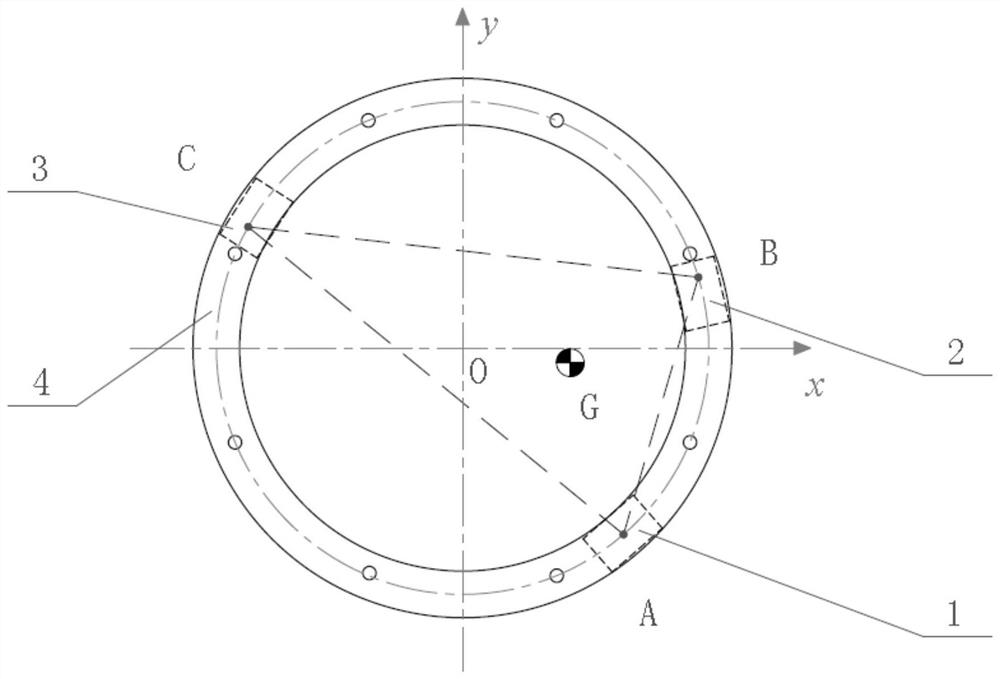

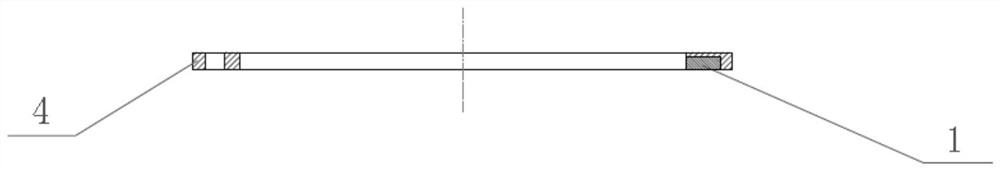

[0021] Such as figure 1 , figure 2 As shown, a gasket for improving the resonance of vertical equipment according to the present invention includes a small gasket A1, a small gasket B2, a small gasket C3, and a large gasket 4.

[0022] The new spacer is in the shape of a ring as a whole, matching with the ring base of the vertical equipment, and the center of the ring is 0 point. The new gasket consists of two materials. The small gasket A1, the small gasket B2, and the small gasket C3 are made of the same material, and the large gasket 4 is made of another material. The large spacer 4 has a circular ring shape as a whole, and several circular bolt holes are arranged on it, so that the connecting bolts of the equipment and the foundation pass through. The small gasket A1, the small gasket B2, and the small gasket C3 are respectively arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com