A Tracking Error Estimation Method for Servo Drive Axis

A servo-driven, tracking error technology, used in the testing of mechanical parts, the testing of machine/structural parts, instruments, etc., can solve the problems of difficult operation, low efficiency, and inability to promote, to overcome difficult operation, fast and accurate. estimated effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

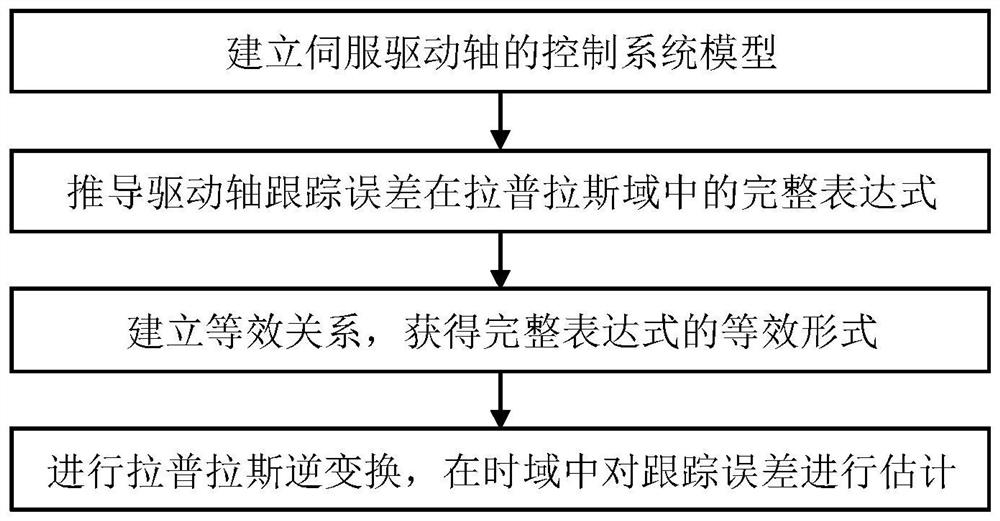

[0026] figure 1 Shown is a flow chart of a tracking error estimation method for a servo drive shaft of the present invention. In order to understand the present invention more clearly, a CNC machine tool servo drive shaft control system is taken as an example for illustration.

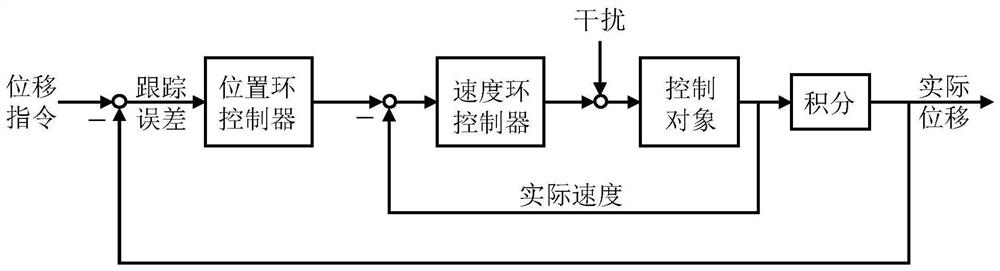

[0027] see figure 2 ,according to figure 2 The block diagram of the CNC machine tool servo drive shaft control system is shown, and the control system model of the servo drive shaft is established as follows:

[0028]

[0029] In the formula, G pc , G vc with G p are respectively the position loop controller, the speed loop controller and the control object of the servo drive shaft, K pp is the proportional gain of the position loop controller, K pv with T v are the proportional gain and integral time constant of the speed loop controller respecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com