Ultrasonic transducer

A transducer and ultrasonic technology, applied in the direction of fluid using vibration, etc., can solve the problems of low sound intensity and unsatisfactory cleaning effect, and achieve the effect of increasing the aesthetic feeling and improving the sound intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

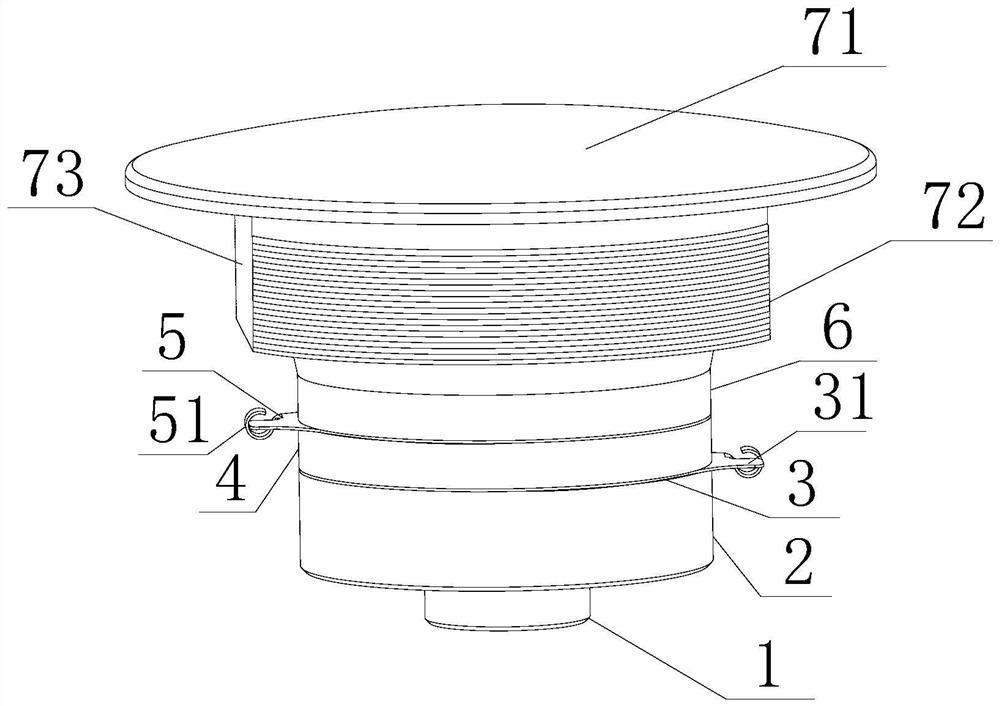

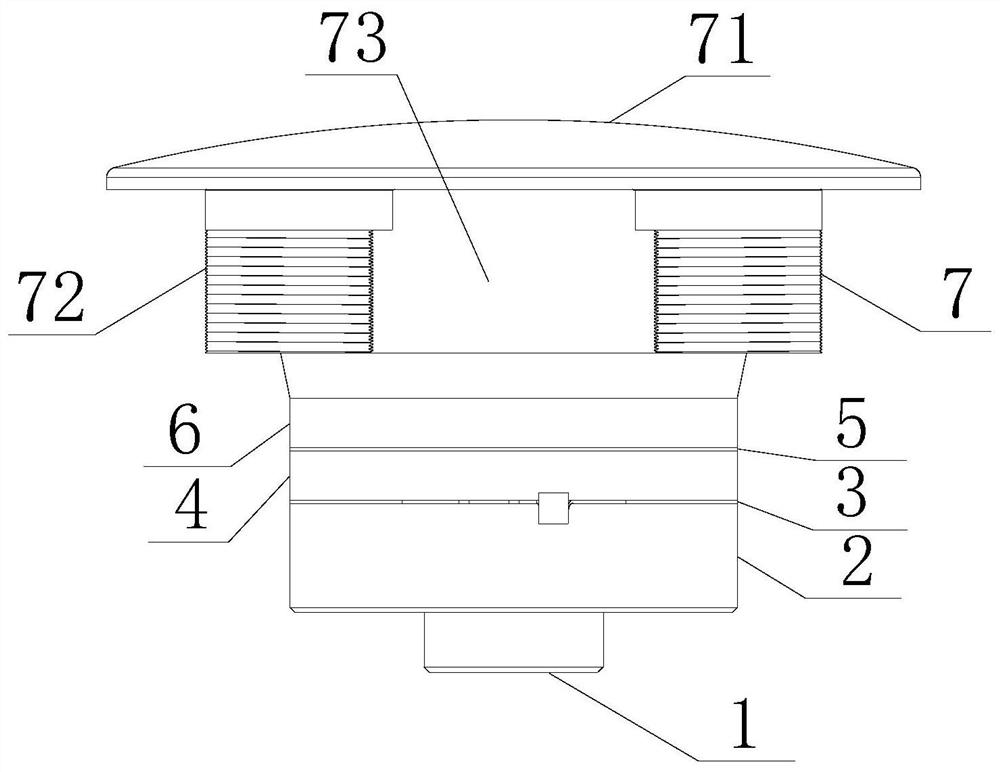

[0026] figure 1 and figure 2 The ultrasonic transducer shown, comprising a lower cap 2 is provided from bottom to top, the first electrode sheet 3, 4 of the first piezoelectric ceramic, the second electrode sheet 5, 6 and second piezoelectric ceramic cover. Lower cap 2, the first electrode sheet 3, 4 of the first piezoelectric ceramic, the second electrode sheet 5, 6 and second piezoelectric ceramic cover from the bottom up through the axis is provided through a locking bolt secured. The top cover is welded or fixed to the cap 7 by glue bonding, the upper end surface of the oscillation 71 is a spherical cap 7. The lower end cap 7 is provided with the connecting portion, the connecting portion is a hollow cylindrical structure, connected to the upper cover portion sleeved on the outer side, is provided with two threaded connecting portions of the outer wall surface 72 and two flat facets 73, 72 and two flanks two flat facets 73 are alternately disposed, and radially symmetrical, t...

Embodiment 2

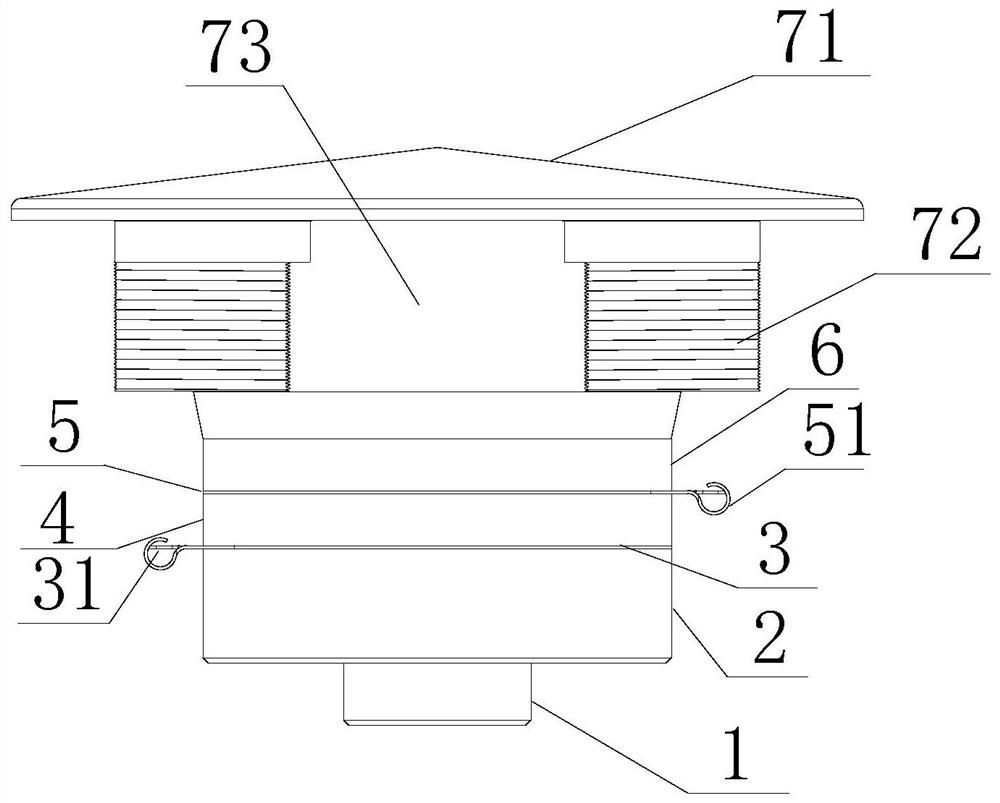

[0028] like image 3 and Figure 4 , The present embodiment is substantially same as a configuration embodiment, except that 71 different shapes of the oscillation plane thereof, which oscillation surface 71 is a tapered surface.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap