Cargo-to-person sowing and sorting integrated workstation and sorting method thereof

A workstation and station selection technology, which is applied to the goods-to-person spreading and picking integrated workstation and its picking field, can solve the problems of limited supply of source boxes at the same time period, little fluctuation of business volume, and low picking efficiency, etc., to increase the average repetition rate. Picking hit rate, strong applicability and integratability, and the effect of enhancing order adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

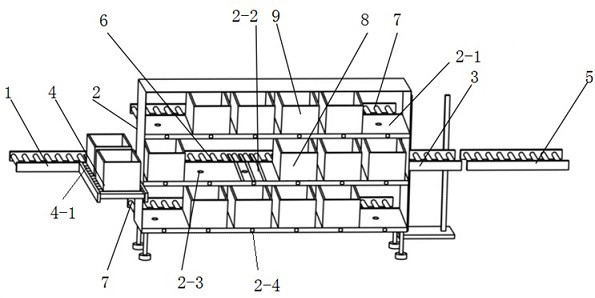

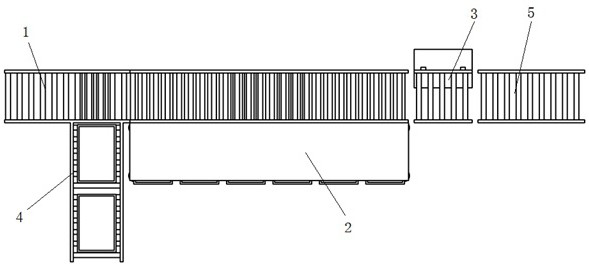

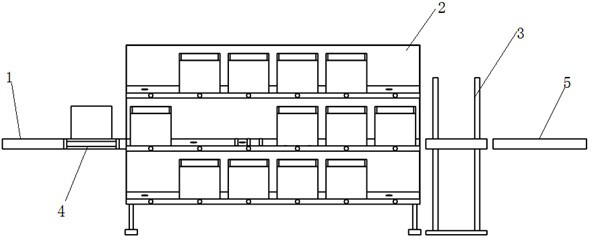

[0058] In order to better understand the technical content of the present invention, specific embodiments are given together with the accompanying drawings for description as follows.

[0059] Existing goods-to-person spreading and picking integrated workstations, such as Figure 7 As shown, a double-layer picking station is adopted (3 sources for 3 orders, etc.), but it is necessary to distinguish between the order box supply layer and the source box supply layer (such as Figure 7 The number 11 is the supply layer, and the number 12 is the delivery layer), so the number and area of source box stations and order box stations are fixed, and cannot be dynamically adjusted according to different order characteristics and order requirements. Adaptability Poor, and relatively speaking, the number of source boxes supplied at the same time is limited, and there are fewer matching orders when picking. Each time the source of goods is supplied to the picking station, the probability o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com