Integrated exhaust manifold cooling jacket

A technology for exhaust manifolds and cooling jackets, applied in liquid cooling, exhaust devices, engine cooling, etc., can solve problems such as easy cracking, difficult sealing, and partial boiling of vapor entrapment, so as to reduce flow requirements and size Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

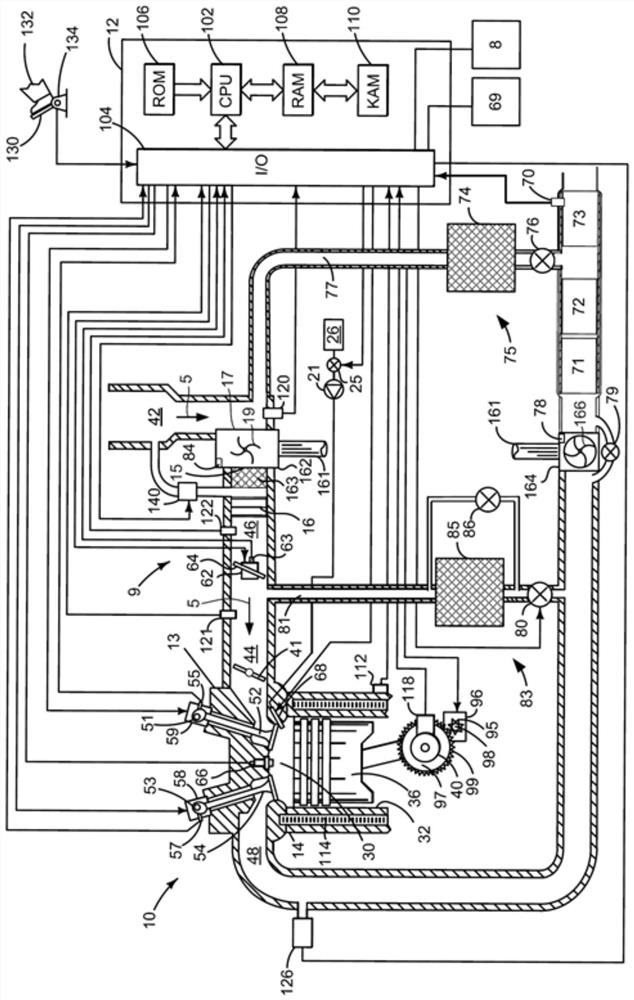

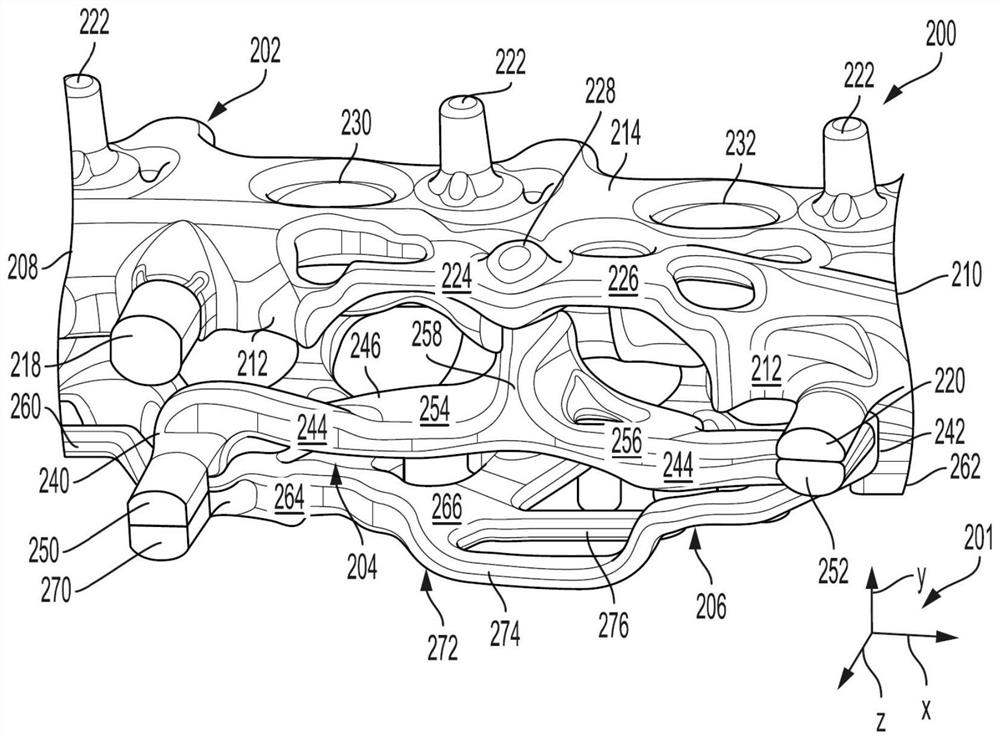

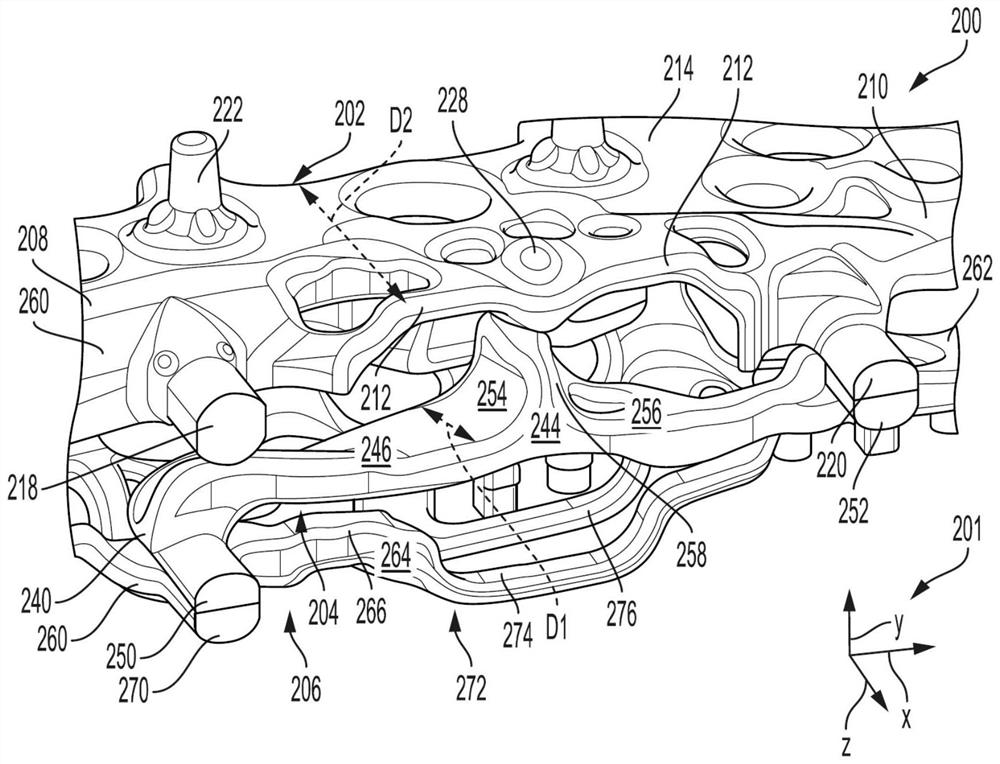

[0018] The following description refers to vehicles such as figure 1 the exhaust system of the vehicle shown). The exhaust system includes an integrated exhaust manifold comprising three exhaust passages integrated in the cylinder head, such as Figure 13 shown. The exhaust passages may be arranged in close proximity with narrow spaces in between. The integrated exhaust manifold may include an upper cooling jacket positioned on a vertical top of the exhaust passage and a lower cooling jacket positioned on a vertical bottom of the exhaust passage. The central cooling jacket can be positioned between the upper cooling jacket and the lower cooling jacket, such as Figure 2 to Figure 6D shown, and positioned between the exhaust passages of the integrated exhaust manifold, as Figure 7 to Figure 8 shown. The center cooling jacket and the upper cooling jacket may be fluidly coupled through drilled passages leading to degassing ports to exhaust coolant gases such as Figure 9 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com