Automatic performance detection method and control device, industrial robot and storage medium

A technology of industrial robots and detection methods, applied in the direction of program control manipulators, manufacturing tools, collaborative operation devices, etc., can solve the problem of increasing test items, etc., to achieve the effect of increasing test items, improving operating efficiency, and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The principles and features of the present invention will be described below in conjunction with specific embodiments, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

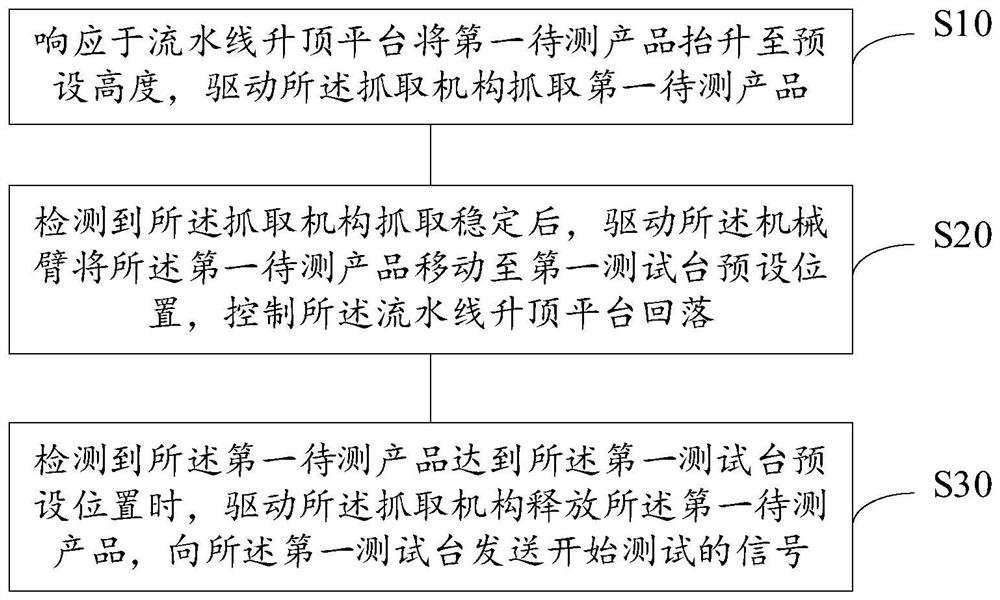

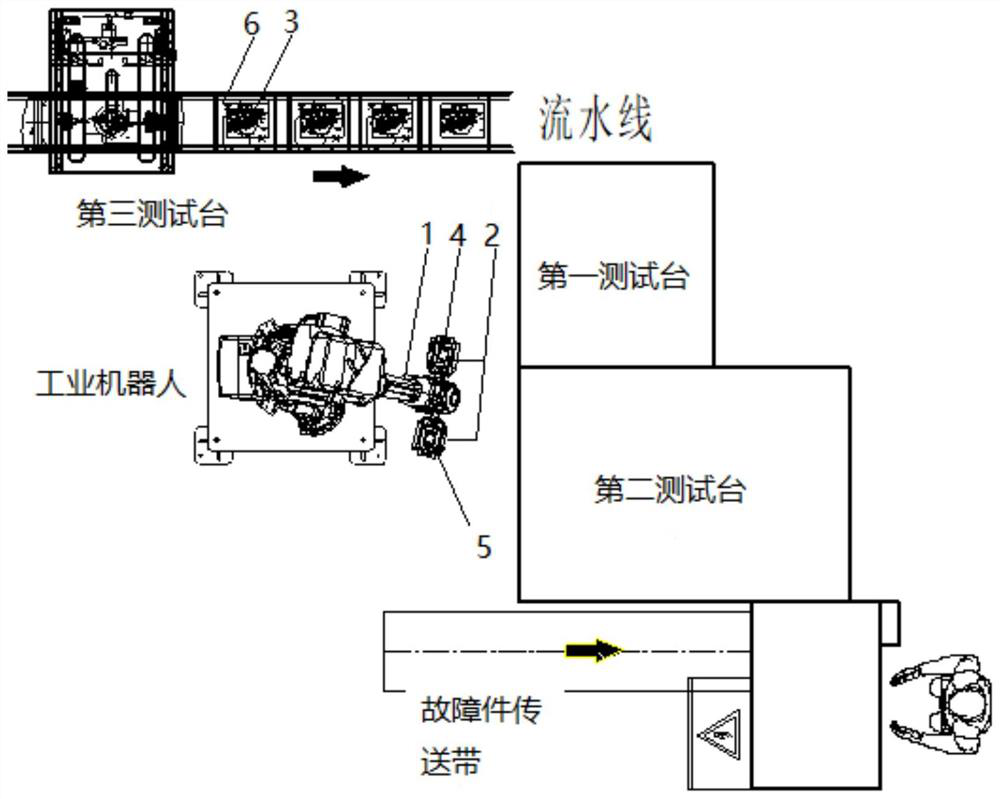

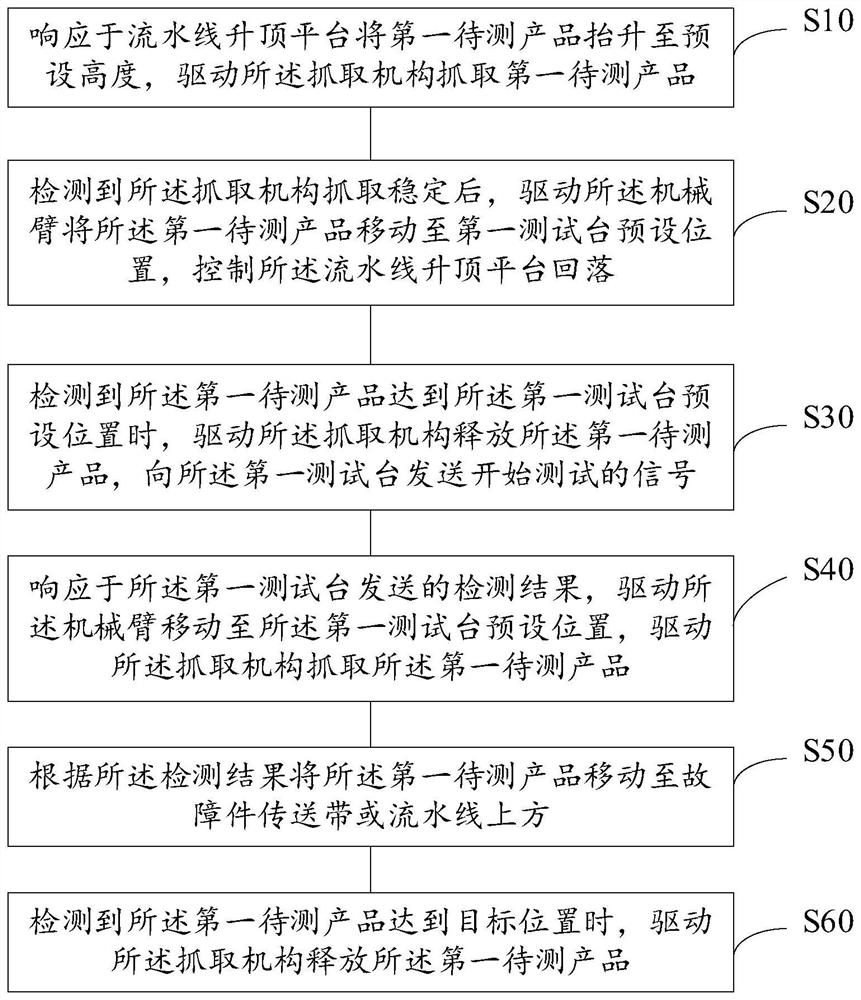

[0054] refer to figure 1 and figure 2 , the present application proposes an automatic performance detection method, which is applied to industrial robots. The industrial robot includes a mechanical arm 1 and a grasping mechanism 2. The grasping mechanism 2 is installed on the front end of the mechanical arm 1. The automatic performance detection The method includes the following steps:

[0055] S10. Lifting the first product to be tested 3 to a preset height in response to the lifting platform of the assembly line, driving the gripping mechanism 2 to grab the first product to be tested 3;

[0056] It is easy to understand that a lifting platform is installed on the assembly line. When the product to be tested flow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com