Polyurethane foam material

A polyurethane foam, polyurethane technology, applied in the field of polyurethane materials, can solve the problems of poor performance, high price, single performance, etc., and achieve the effects of improving mechanical properties, improving service life, and improving moisture absorption performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

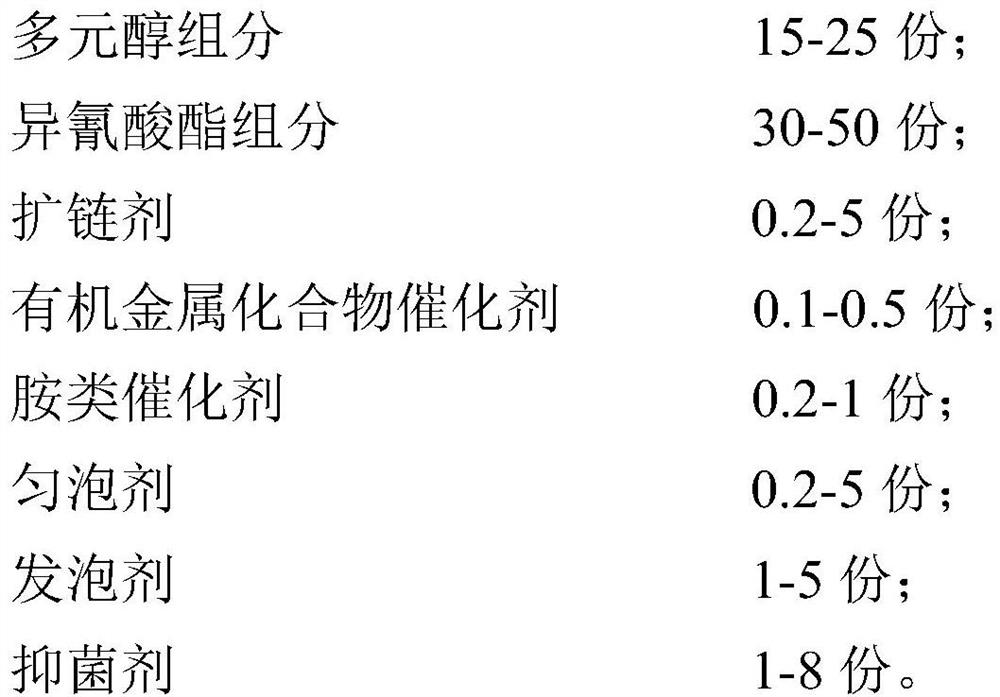

[0051] A kind of polyurethane foam material, composition is as follows by mass ratio:

[0052] 16 parts of polyol components;

[0053] 32 parts of isocyanate component;

[0054] 4 parts of chain extender;

[0055] 0.2 part of organometallic compound catalyst;

[0056] 0.3 part of amine catalyst;

[0057] 0.5 parts of foam stabilizer;

[0058] 2 parts foaming agent;

[0059] 4 parts of antibacterial agent.

[0060] Wherein, the polyol component is a mixture of castor oil polyol (f=2.7, hydroxyl value 163mgKOH / g) and pentaerythritol (mass ratio 4:1);

[0061] The isocyanate component is liquid MDI;

[0062] The chain extender is 1,4-butanediol;

[0063] The organometallic compound catalyst is dibutyltin oxide;

[0064] The amine catalyst is 4-methoxyethylmorpholine;

[0065] The foam stabilizer is U.S. Momentive high resilience silicone oil Y-10366;

[0066] Described whipping agent is calcium bicarbonate;

[0067] The antibacterial agent is (trimethoxysilylpropyl) o...

Embodiment 2

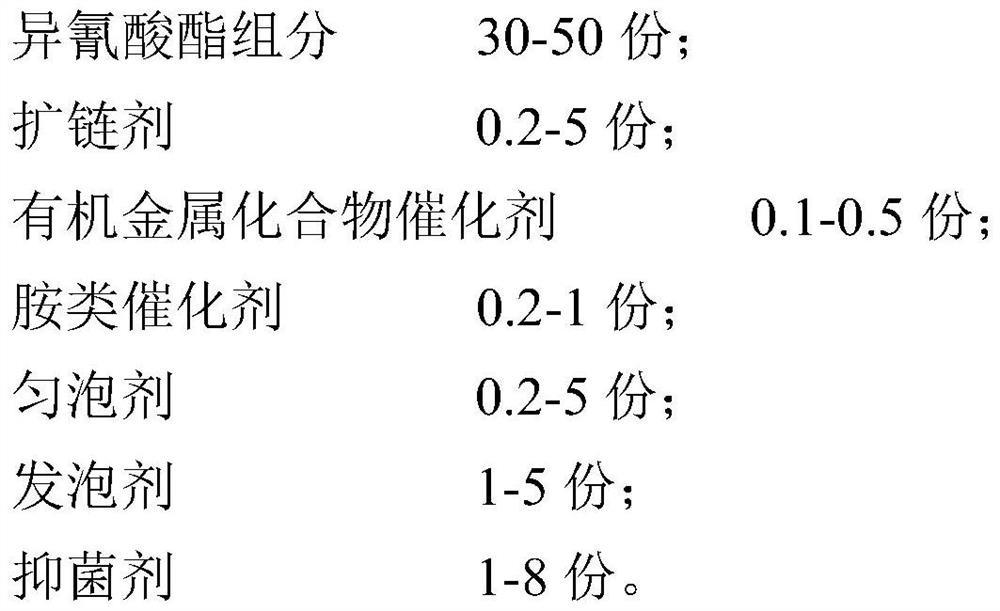

[0073] A kind of polyurethane foam material, composition is as follows by mass ratio:

[0074] 20 parts of polyol component; 40 parts of isocyanate component; 0.8 part of chain extender; 0.3 part of organometallic compound catalyst; 0.3 part of amine catalyst; 2 parts of foam stabilizer; 2 parts of foaming agent; 6 parts of antibacterial agent.

[0075] Wherein, the polyol component is a blend of castor oil polyol (f=2.7, hydroxyl value 163mgKOH / g) and polyethylene glycol (mass ratio 5:1);

[0076] The isocyanate component is TDI;

[0077] The chain extender is 1,6-hexanediol;

[0078] The organometallic compound catalyst is stannous octoate;

[0079] The amine catalyst is two-(2-dimethylaminoethyl) ether;

[0080] The foam stabilizer is U.S. Momentive high resilience silicone oil Y-10366;

[0081] The whipping agent is water;

[0082] Described antibacterial agent is (trimethoxysilyl propyl) octadecyl dimethyl ammonium chloride;

[0083] The preparation of polyurethane ...

Embodiment 3

[0088] A kind of polyurethane foam material, composition is as follows by mass ratio:

[0089] 25 parts of polyol component; 50 parts of isocyanate component; 5 parts of chain extender; 0.2 part of organic metal compound catalyst; 0.2 part of amine catalyst; 1.7 parts of foam stabilizer; 1.7 parts of foaming agent; 7 parts of antibacterial agent.

[0090] The polyol component is a blend of castor oil polyol (f=2.7, hydroxyl value 163mgKOH / g) and 1,4-butanediol (mass ratio 5:1);

[0091] The isocyanate component is polymeric MDI;

[0092] The chain extender is 1,4-butanediol;

[0093] The organometallic compound catalyst is isopropyl titanate;

[0094] The amine catalyst is N,N-dimethylcyclohexylamine;

[0095] The foam stabilizer is U.S. Momentive high resilience silicone oil Y-10366;

[0096] The whipping agent is water;

[0097] Described antibacterial agent is (trimethoxysilyl propyl) octadecyl dimethyl ammonium chloride;

[0098] The preparation of polyurethane foam ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com