Adjustable mounting structure for arc-shaped assembly-type suspended ceiling

An installation structure and assembly technology, applied in the direction of ceilings, building components, building structures, etc., can solve the problems of difficult adjustment and installation accuracy, and achieve the effect of improving accuracy and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

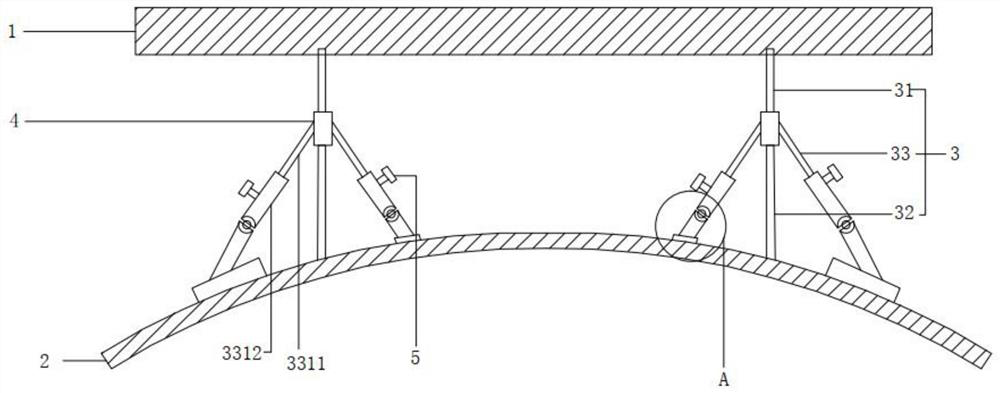

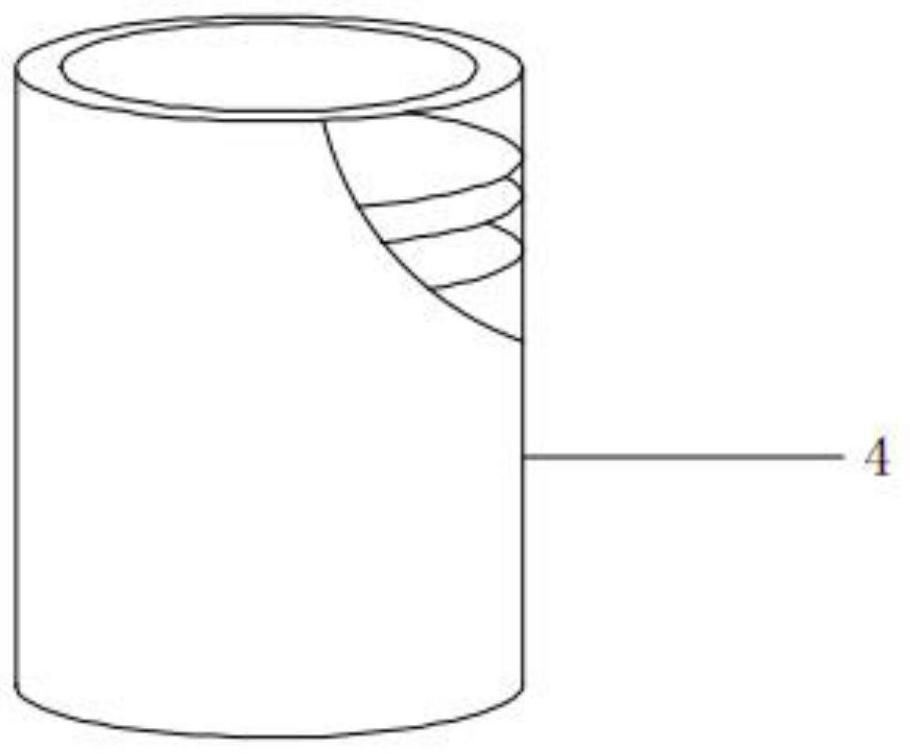

[0023] see Figure 1 to Figure 3 , the figure shows an adjustable installation structure of an arc-shaped assembly type suspended ceiling provided by Embodiment 1 of the present invention, which includes a top base layer 1 on which an arc-shaped veneer 2 is installed, and the arc-shaped veneer 2 is connected with the A plurality of adjustment mechanisms 3 are arranged between the top base layers 1. The adjustment mechanisms 3 include a first ceiling rod 31, a second ceiling rod 32 and two adjustment parts 33. The first ceiling rod 31 is fixedly connected to the top base layer 1. A sleeve 4 is connected to the bottom of the first ceiling rod 31, the second ceiling rod 32 is connected to the other end of the sleeve 4, and the opposite end of the second ceiling rod 32 is connected to the curved decorative panel 2, and the adjusting part 33 includes an adjusting rod 331 and connecting rod 332, one end of adjusting rod 331 is connected on the sleeve 4, and the other end of adjustin...

Embodiment 2

[0029] see Figure 1 to Figure 3 , the figure shows an adjustable installation structure of an arc-shaped assembled ceiling provided by Embodiment 2 of the present invention. On the basis of the above-mentioned embodiments, this embodiment further makes the following technical solutions as improvements: adjustment The rod 331 is a telescopic rod, and the adjusting rod 331 includes a first adjusting rod 3311 and a second adjusting rod 3312. One end of the first adjusting rod 3311 is connected to the sleeve 4, and the other end of the first adjusting rod 3311 is telescopically connected to the second adjusting rod 3311. On the adjustment rod 3312. The second adjusting rod 3312 is provided with a bolt 5 , and the bottom of the bolt 5 is against the surface of the first adjusting rod 3311 . Through the setting of the above structure, the adjustment between the first ceiling rod and the second ceiling rod can not be affected, and it can be changed according to the distance between...

Embodiment 3

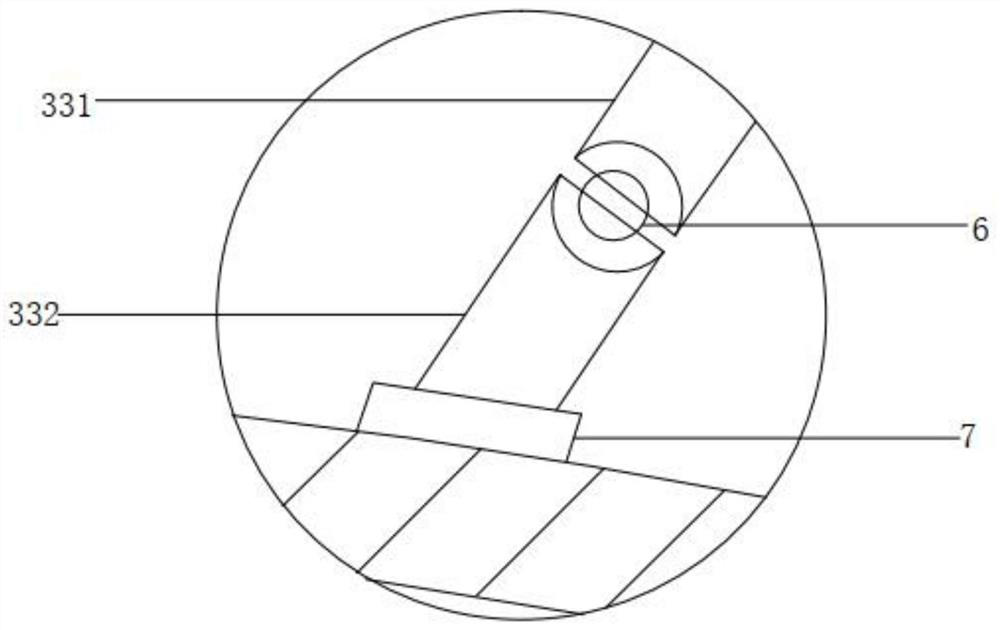

[0031] see Figure 1 to Figure 3 , the figure shows an adjustable installation structure of an arc-shaped assembled ceiling provided by Embodiment 3 of the present invention. On the basis of the above-mentioned embodiments, this embodiment further makes the following technical solutions as improvements: the first The two adjusting rods 3312 are connected with the connecting rod 332 through the rotating part 6, and the rotating part 6 is a ball shaft. Through the setting of the above structure, the ball shaft is beneficial to adjust the angle, which can make the second adjusting rod and the connecting rod form a two-link structure, and the adjustment is more flexible.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com