Steeply inclined coal seam filling mining method and application

A mining method and steep inclination technology are applied in the field of backfilling and mining of steeply inclined coal seams, and can solve the problems of low efficiency, harsh working environment, and inability to fully exploit and utilize steeply inclined coal seams.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

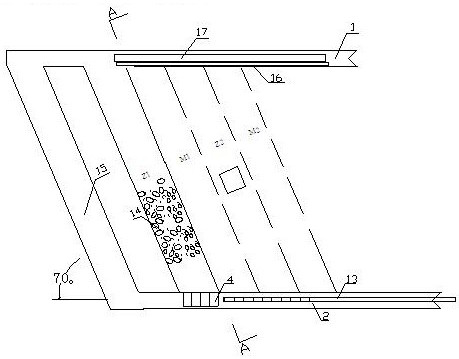

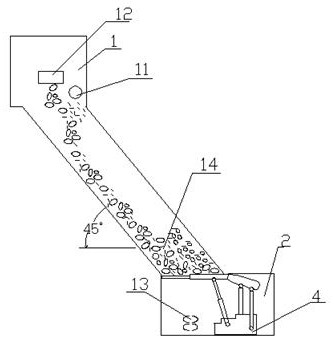

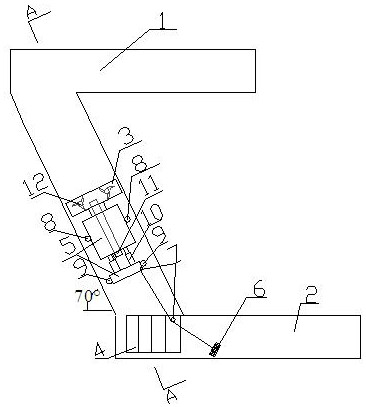

[0027] A filling mining method for a steeply inclined coal seam comprises the following steps,

[0028] (1) Excavation transportation lane, air return lane and cut-outs: excavate the transportation lane (lower level lane 2) and return air lane (upper level lane 1) according to the longwall working face system, and arrange coal gangue tape at the upper return air lane Conveyor 17 and mixed slurry pipeline 16, arrange raw coal scraper conveyor 13 at the lower transportation lane; use a sharply inclined continuous miner with temporary support at the designed cutting eye position to open a pseudo-inclined edge cutting with a pseudo-inclination angle not greater than 45º Eye 15 is used as a permanent ventilation pedestrian passage on this working face;

[0029] (2) Then use the steeply inclined continuous mining machine with temporary support to mine the pseudo-inclined branch road Z1 with a width of 3-8m at a distance of 3-8m from the side cutout. The steeply inclined coal seam ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com