Steep-dip sectional extraction integrated top coal caving and coal-mining method

A coal mining method and top-coal caving recovery technology, which is applied to mining equipment, ground mining, mining equipment, etc., can solve the problems of difficult support, large number of tunnels, poor safety, etc., and achieve simple and effective support, reduce Coal seam mining work, the effect of strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

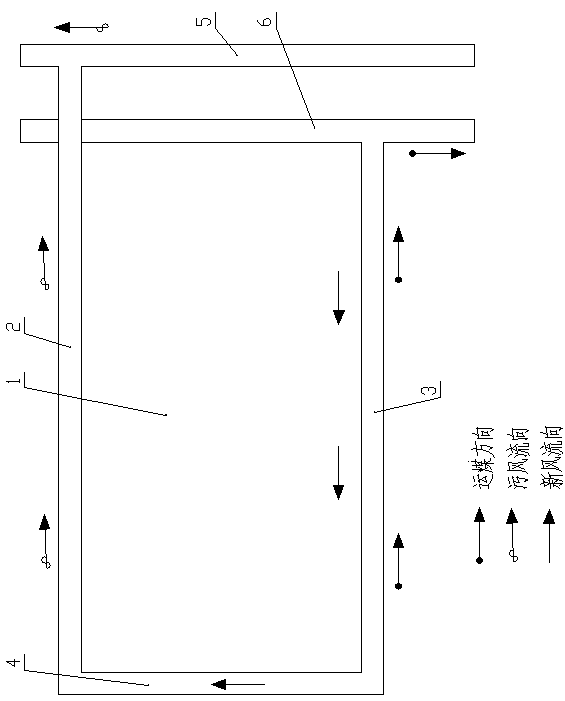

[0022] Such as figure 1 Shown, the integrated top-coal caving coal mining method of steeply inclined segmental excavation of the present invention comprises the following steps,

[0023] (1) Select a coal seam with a thickness of 3-4m and a coal seam dip greater than 55° as the coal seam 1 to be mined;

[0024] (2) Divide the coal seam 1 into several mining areas. In one mining area, divide the coal seam 1 into several rectangular sections along the inclination direction of the coal seam 1 in a certain length. The length of each section is 50m. The inclination length of coal seam 1 is 8~10 times the roadway height;

[0025] (3) Mining the lowermost section of the mining area first, arrange the air return roadway 2 and the recovery roadway 3 along the strike length in the upper and lower parts of the section, and arrange the air return roadway 2 and the mining roadway 3 in the left side of the block along the coal seam 1 The first cut roadway 4 is arranged in the inclined dir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com