Electrochromic film driving control method and device, and computer readable storage medium

An electrochromic film and equipment technology, which is applied to instruments, nonlinear optics, optics, etc., can solve the problems of single electrochromic film control scheme, poor user experience, and insufficient effects, and achieve a simple and reliable scheme. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

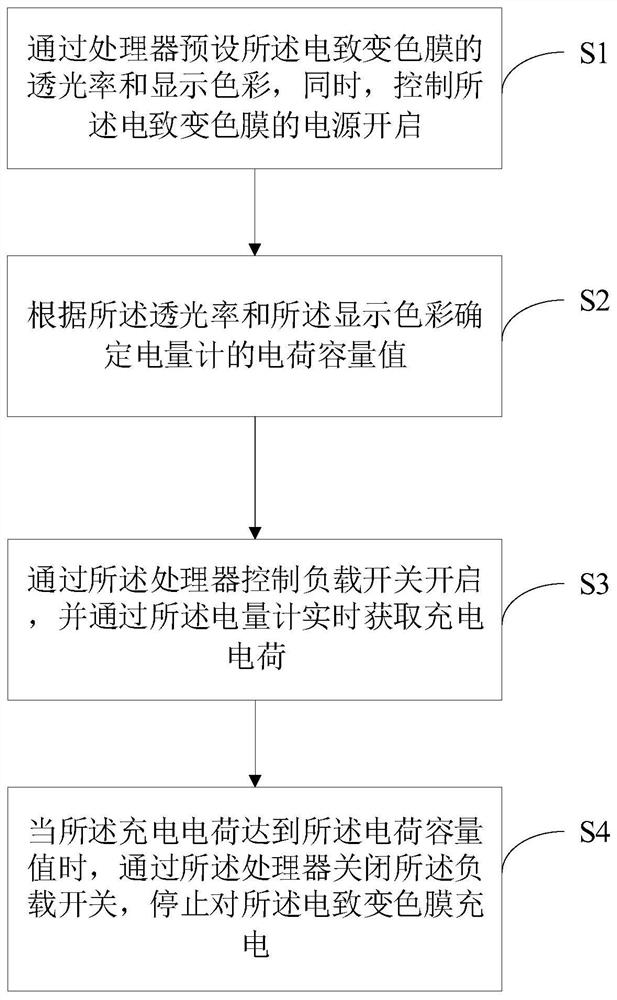

[0078] image 3 It is a flow chart of the first embodiment of the electrochromic film drive control method of the present invention. A driving control method for an electrochromic film, the method comprising:

[0079] S1. Preset the light transmittance and display color of the electrochromic film through the processor, and at the same time, control the power of the electrochromic film to be turned on;

[0080] S2. Determine the charge capacity value of the fuel gauge according to the light transmittance and the display color;

[0081] S3, controlling the load switch to be turned on by the processor, and obtaining charging charges in real time through the fuel gauge;

[0082] S4. When the charging charge reaches the charge capacity value, turn off the load switch by the processor to stop charging the electrochromic film.

[0083] In this embodiment, first, the light transmittance and display color of the electrochromic film are preset by the processor, and at the same time, ...

Embodiment 2

[0092] Figure 4 It is a flow chart of the second embodiment of the electrochromic film driving control method of the present invention. Based on the above embodiment, the light transmittance and display color of the electrochromic film are preset through the processor, and at the same time, the electrochromic film is controlled to Power on for the chromic film, including:

[0093] S11. Presetting the full light transmission mode and the non-light transmission color mode of the electrochromic film;

[0094] S12. Determine positive and negative DC voltages of the power supply respectively according to the full light transmission mode and the non-light transmission color mode.

[0095] In this embodiment, firstly, the full light transmission mode and the non-light transmission color mode of the electrochromic film are preset; then, the power supply is determined according to the full light transmission mode and the non-light transmission color mode respectively. positive and n...

Embodiment 3

[0105] Figure 5 It is a flowchart of the third embodiment of the electrochromic film drive control method of the present invention. Based on the above embodiments, the determination of the charge capacity value of the fuel gauge according to the light transmittance and the display color includes:

[0106] S21. In the full light transmission mode, determine a first charge capacity value of the fuel gauge according to the light transmittance;

[0107] S22. In the non-light-transmitting color mode, determine a second charge capacity value of the fuel gauge according to the display color.

[0108]In this embodiment, first, in the full light transmission mode, the first charge capacity value of the fuel gauge is determined according to the light transmittance; then, in the non-light transmission color mode, according to the The display color determines a second charge capacity value of the fuel gauge.

[0109] Optionally, in the non-light-transmitting color mode, according to th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com