A cigarette fly ash detection device and detection method based on machine vision using gray level difference method

A machine vision and detection device technology, applied in the direction of instruments, chemical analysis by combustion, image analysis, etc., can solve the problems of short duration of fly ash state, large number of measurement samples, high measurement accuracy requirements, etc., and achieve easy promotion and detection The effect of fast method, accurate and simple detection method

Active Publication Date: 2021-08-24

CHINA TOBACCO YUNNAN IND

View PDF3 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] Due to the lack of existing detection technology, at the same time, due to the characteristics of fly ash indicators in the cigarette burning process, it has the characteristics of high measurement accuracy, large number of measurement samples, and short duration of fly ash state, so it is difficult to detect manually

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

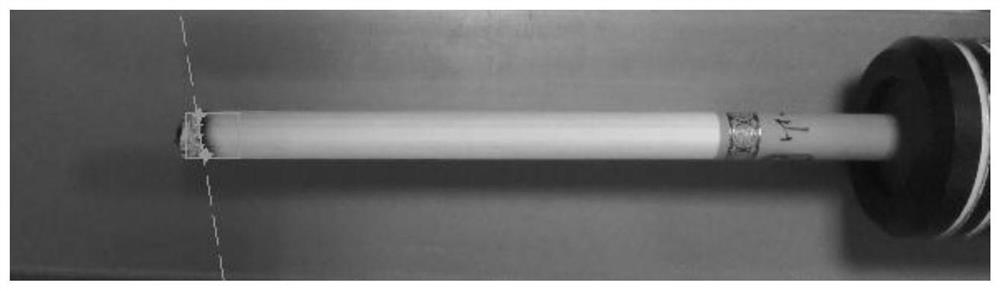

[0088] In this embodiment, during the detection process, the LED light source is used to illuminate and fill the sample detection environment during the image collection process, in order to ensure sufficient and stable light in the detection environment and reduce the interference of the external environment on image collection.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

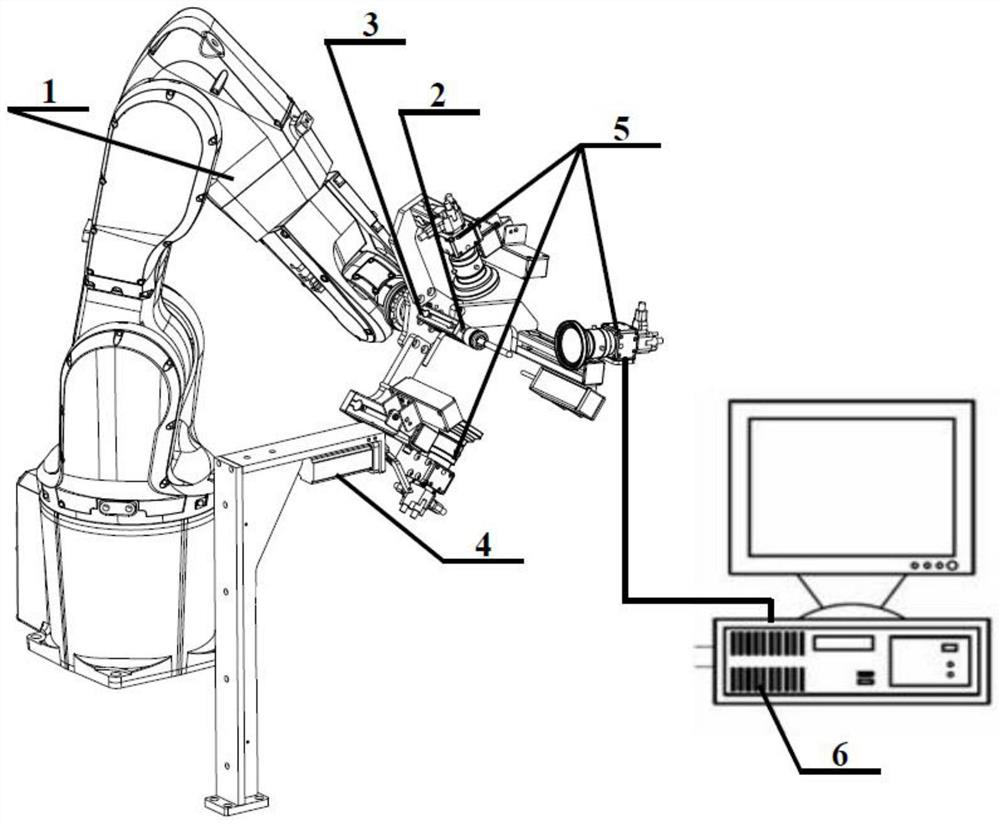

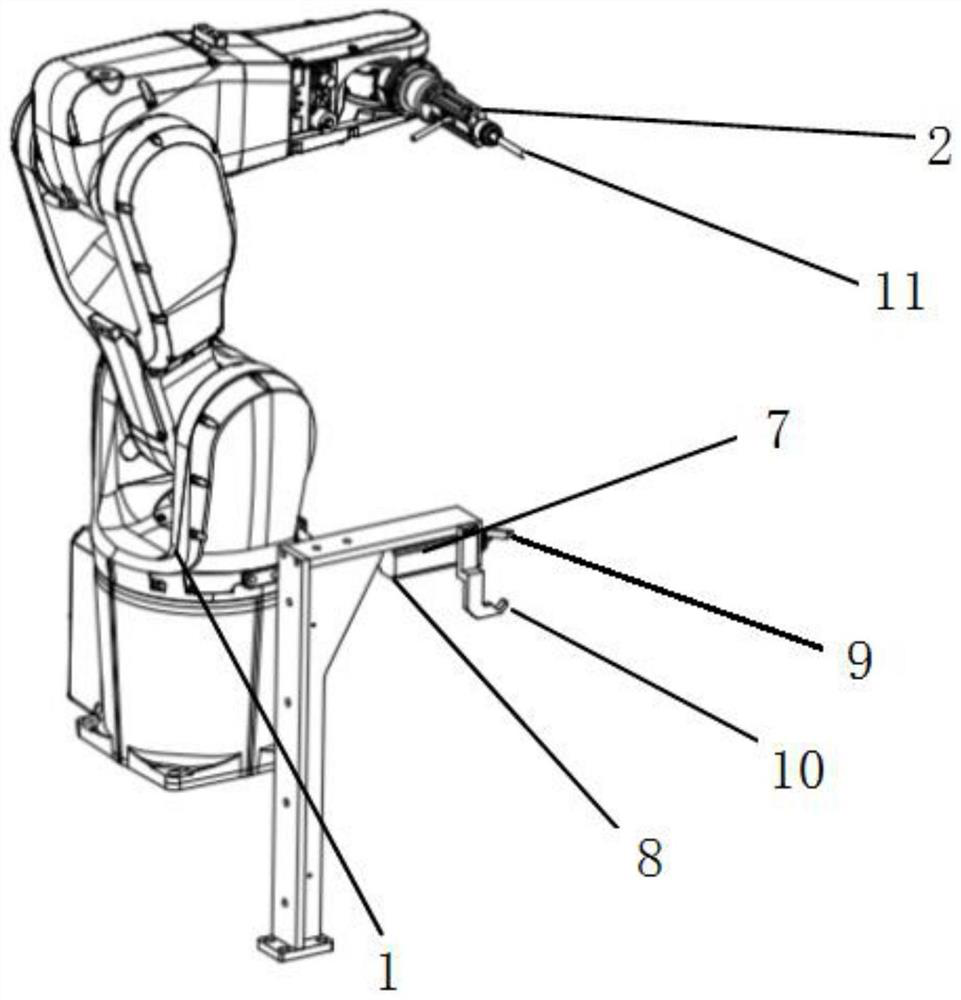

The invention discloses a machine vision-based cigarette fly ash detection device and a cigarette fly ash detection method using a gray scale difference method. The invention clamps and detects samples by simulating human cigarette smoking action manipulators. During the simulating human smoking process, multiple groups of cameras are used to follow up the cigarette burning process with full information and real-time synchronously. Compare the difference to judge whether there is fly ash phenomenon, and calculate the area of fly ash in the cigarette combustion ash column through the area where the gray level of the cigarette combustion ash column in the two cigarette combustion ash column images is different before and after, so as to further judge the amount of fly ash size. The present invention cleverly converts the detection of the amount of fine fly ash into the detection of the gray difference of the cigarette burning ash column. Compared with the method of using manual suction experience and subjective judgment of whether the cigarette has fly ash and the size of the fly ash, the repeatability of the method is Good, objective, highly credible, and quantifiable, and can more accurately evaluate product differences.

Description

technical field [0001] The invention belongs to the technical field of cigarette fly ash detection, and relates to a method for detecting cigarette fly ash, in particular to a cigarette fly ash detection device and detection method based on machine vision using a gray scale difference method. The method uses machine vision to track cigarettes in real time Combustion state, using image processing to judge, compare and calculate the situation of cigarette fly ash. Background technique [0002] With the development of cigarette technology and the continuous improvement of consumers' requirements for cigarette smoking quality, the ash-coating performance of cigarettes in the smoking process has attracted more and more attention from consumers. There are also unfavorable conditions such as polluting the environment and consumer clothes, so how to improve the ash-coating performance of cigarettes has always been one of the important research directions of the tobacco industry. ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): G06T7/90G06T7/62G06T7/292G06T7/254G06T7/00G01N31/12

CPCG06T7/90G06T7/0002G06T7/254G06T7/292G06T7/62G01N31/12G06T7/001G06T2207/30128G06T7/0004

Inventor 郑晗詹建波王浩余振华李赓张莹王涛程量余婷婷丁海燕王旭谢姣李利伟孔令汉姜黎杨帅

Owner CHINA TOBACCO YUNNAN IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com