Whole-pitch motor stator

A motor stator and full-pitch technology, applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve the problems of narrow selection range of voltage and current, failure of motor to meet demand, low fault tolerance and low reliability, and achieve improved stator slot The effect of full rate, improved material utilization, and strong fault tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

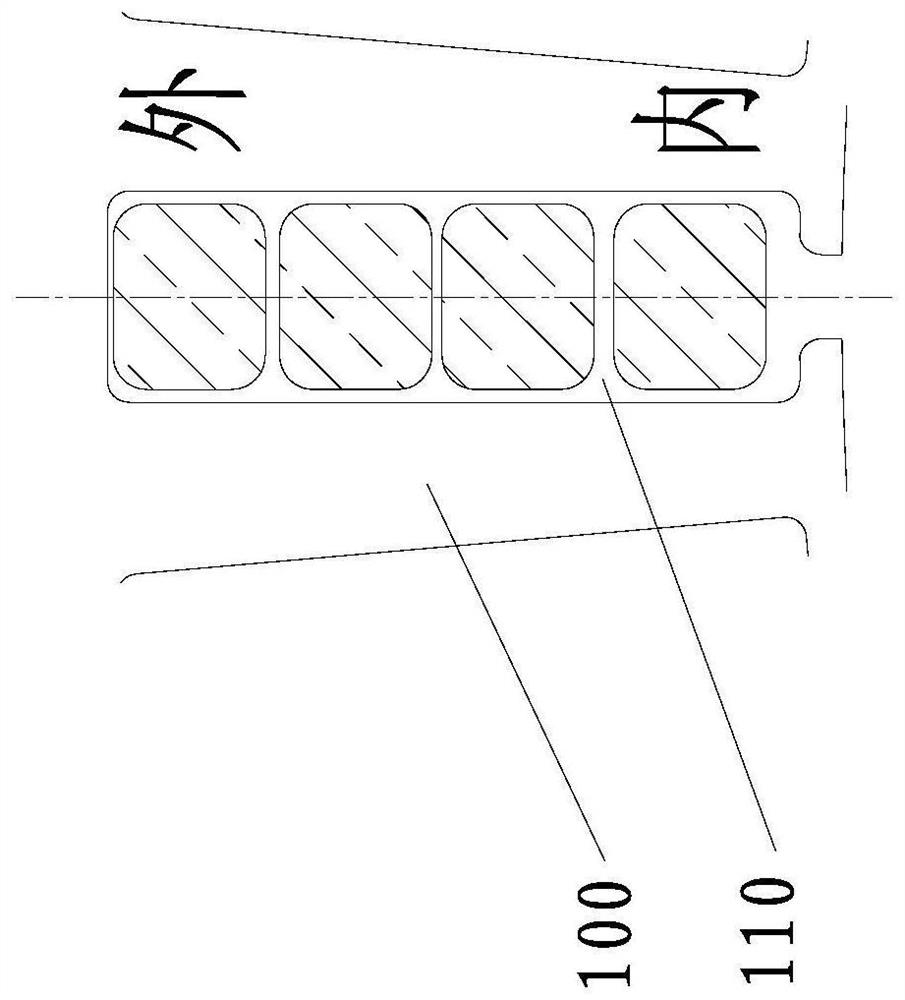

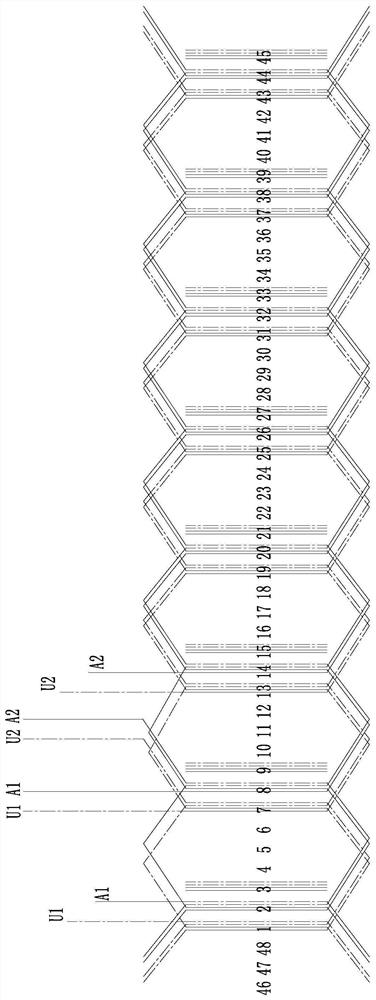

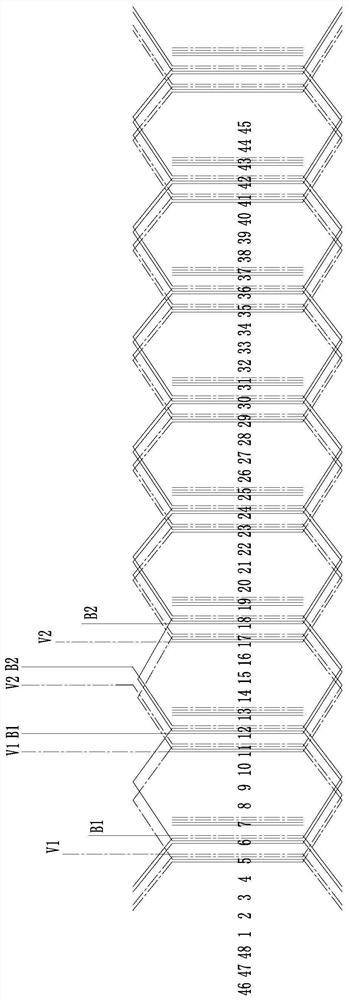

[0030] Such as Figure 1-Figure 6 As shown, the present embodiment provides a full-pitch motor stator, including an iron core 100 and a stator winding wound on the iron core, wherein 48 stator slots 110 are provided at equal intervals on the iron core 100, and the stator slots 110 The shape can be a conventional shape, such as a rectangular slot, and insulating paper is arranged in each stator slot 110. The insulating paper is also the insulating paper used in the stator of a conventional motor. From the outside to the inside, it is divided into the first layer, the second layer, the third layer and the fourth layer, and each layer is used to wind the stator coil, that is, four wires in one slot. In order to distinguish the stator slots 110 at different positions, in this embodiment, starting from any stator slot 110, the stator slots 110 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com