Stator winding of flat wire motor

A motor stator and winding technology, which is applied to the shape/style/structure of windings, electric components, winding conductors, etc., can solve the problems of difficult manufacturing process of wire-embedded stator, reduce the difficulty of manufacturing process and improve the yield of mass production , reduce the effect of circulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The specific embodiment of the present invention is described further below according to accompanying drawing:

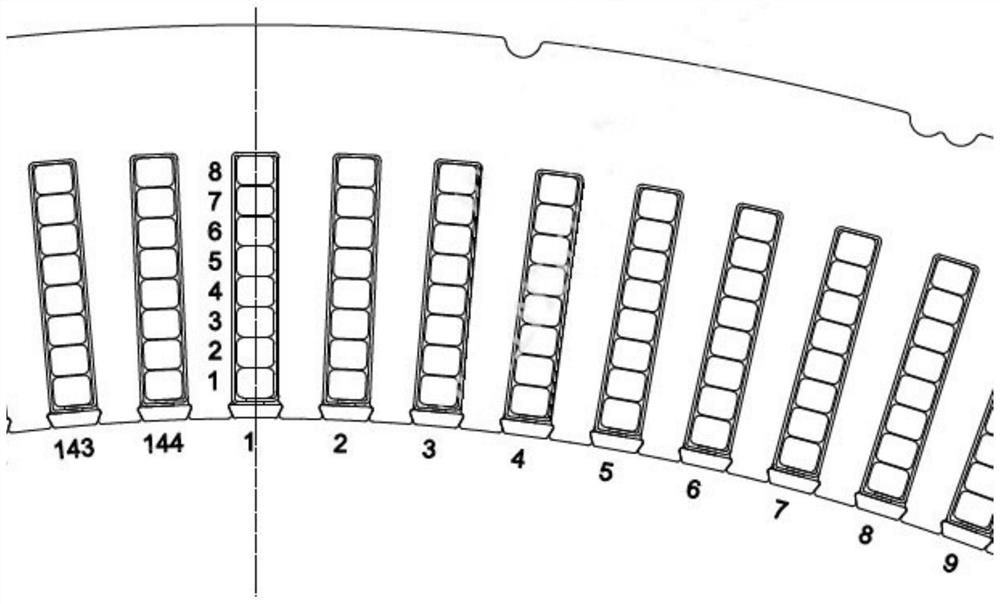

[0040] This embodiment provides a flat-wire motor stator winding, including a wire-embedded stator. The appearance of the wire-embedded stator is as follows: Figure 5 shown. The embedded wire stator uses flat wire (square wire) for off-line; the stator core in the embedded wire stator contains 6 or more even-numbered flat wires in each stator slot, and the winding contains at least 2 (or a multiple of 2 above) ) branch winding.

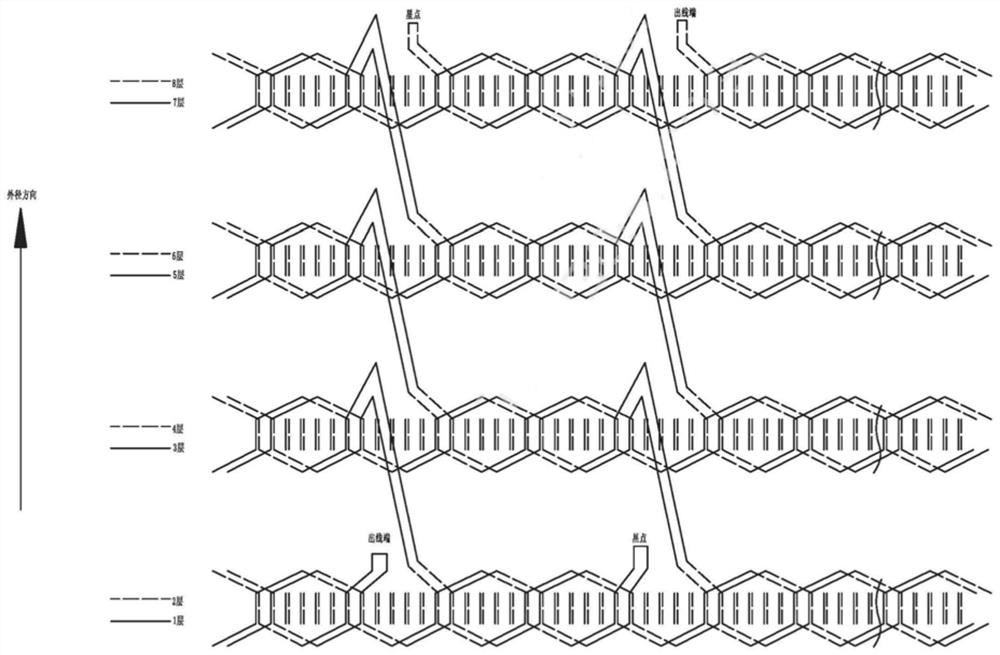

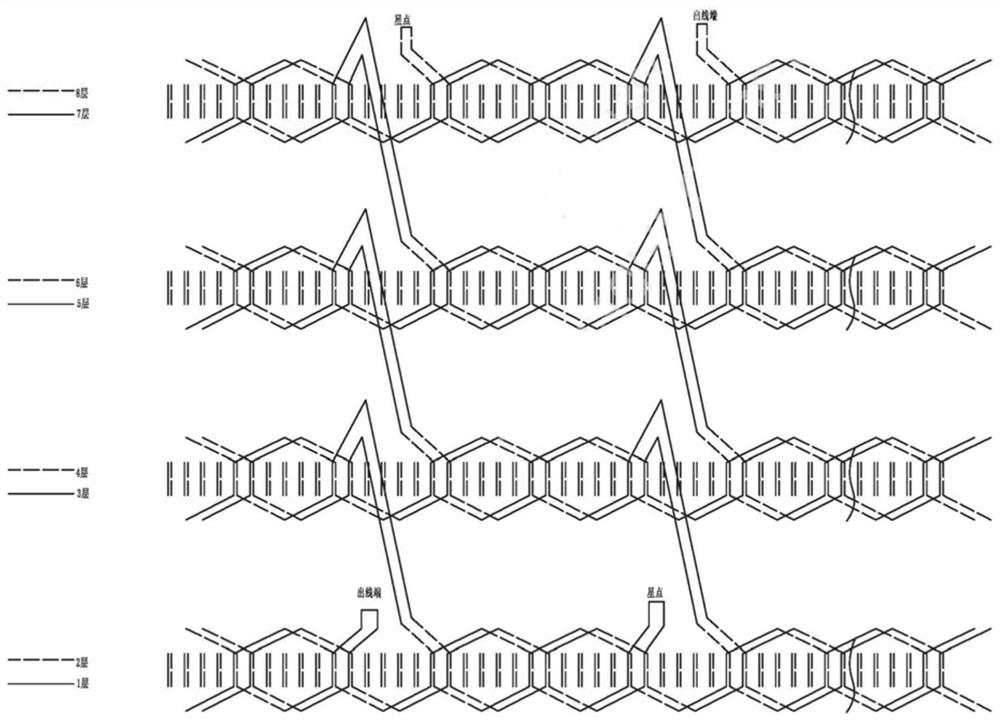

[0041] The windings are evenly arranged in the iron core stator slots with a certain span, and two adjacent copper wires in each stator slot form a layer of windings. Taking a three-phase motor as an example, when q=2, each stator slot contains 8 flat wires as an example, and the normal span in each layer of wires includes the first wire of the first stator slot (that is, the first layer) Cross to the 2nd wire of the 7th stator s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com