ISG (Integrated Starter Generator) driven motor coil

A technology for driving motors and coils, applied in the shape/style/structure of winding conductors, etc., can solve the problems of difficulty in meeting the requirements of the coil end size of the ISG drive motor, the difficulty of manufacturing the ISG drive motor, and the short axial dimension, etc. Achieve compact structure, reduce end height and reduce connection length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings, and the protection scope of the present invention is not limited to the following description.

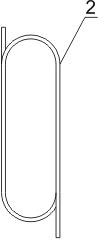

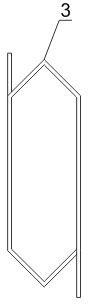

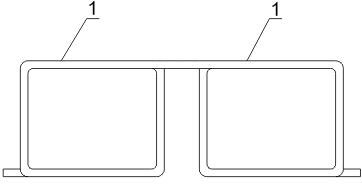

[0016] like image 3 and Figure 4 As shown, the ISG drives the motor coil, which includes a plurality of coil elements 1. The coil element 1 is a hollow cylinder formed by winding and stacking a complete wire in a rectangular manner in the longitudinal direction. The end of the coil element 1 is connected to the adjacent coil The starting point of element 1 is connected.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com