Cosmetic raw material screening equipment

A technology for screening equipment and cosmetics, which is applied in the fields of filtration, chemical instruments and methods, solid separation, etc., can solve the problems of difficult-level cosmetics quality and low screening efficiency, and achieve convenient use, simple operation, accelerated screening speed and collection speed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

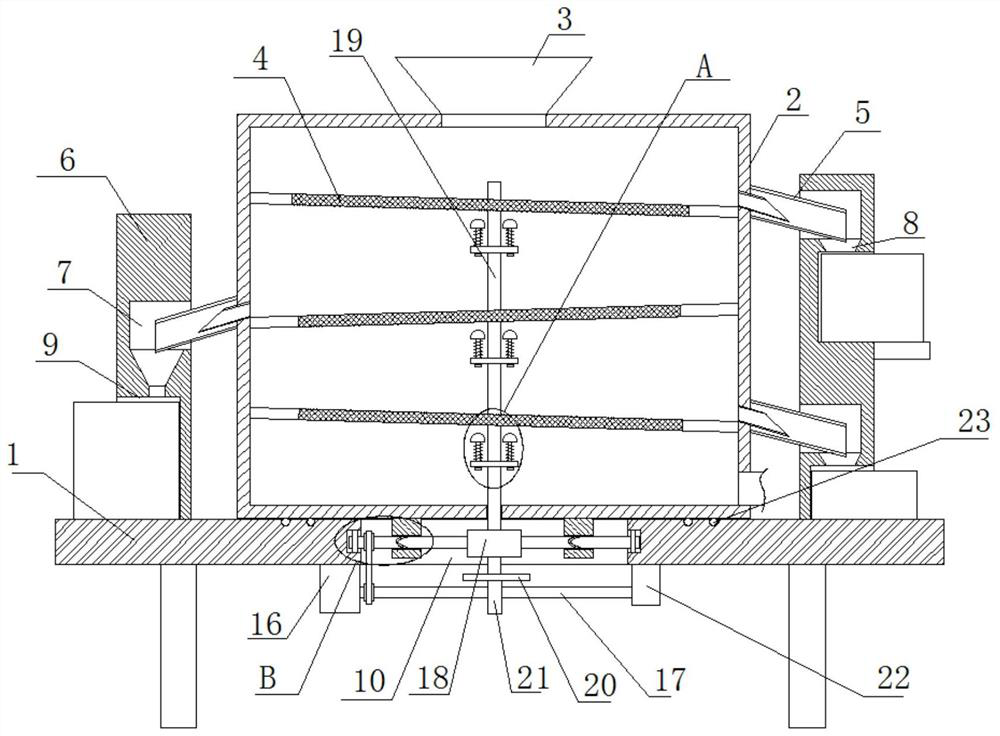

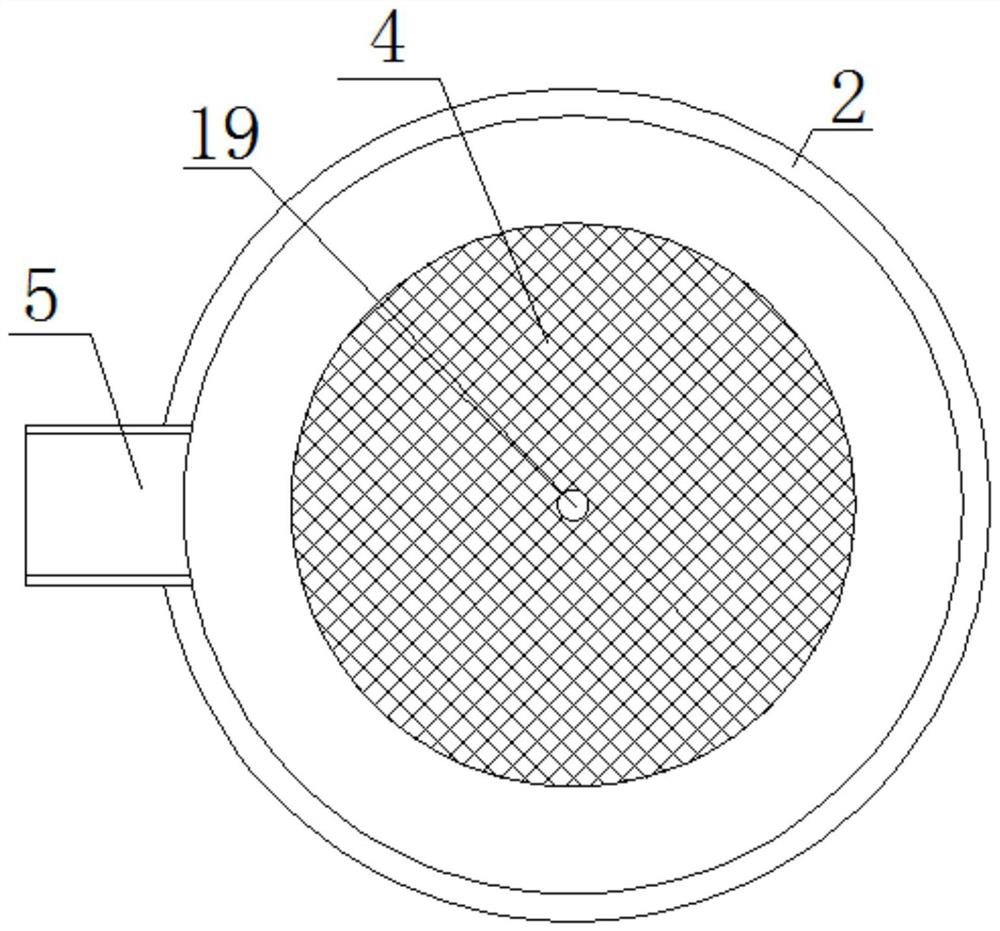

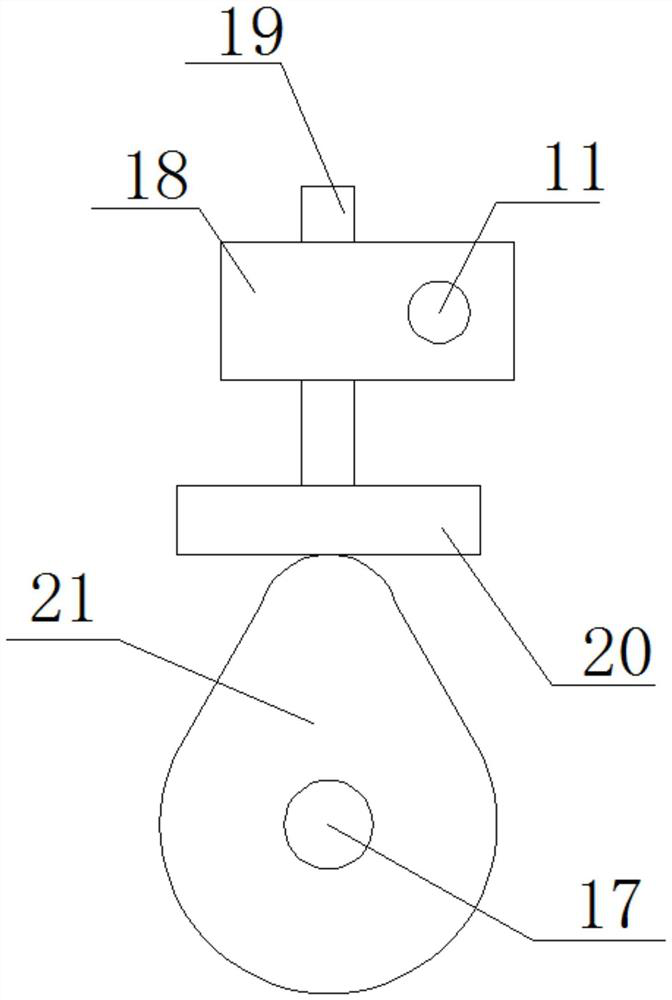

Embodiment 1

[0027] refer to Figure 1-5 , a kind of equipment for screening cosmetic raw materials, including an operation console 1, a casing 2 is slidably connected to the top of the operation console 1, a feeding hopper 3 is fixedly installed on the top of the casing 2, and three filter filters are fixedly installed on the inner wall of the casing 2. The filter plate 4 and the inner wall of the housing 2 form a certain angle, and the two adjacent filter plates 4 are centrally symmetrical, and the filter holes on the three filter plates 4 gradually decrease from top to bottom, and the housing Two and one discharge hoppers 5 are respectively fixedly installed on both sides of the 2, and the discharge hopper 5 is matched with the corresponding filter plate 4. The top of the operating table 1 is fixedly installed with two symmetrically arranged support seats 6, and the two support seats 6 There are two and one feed inlet 7 on the side close to each other respectively, the feed inlet 7 is m...

Embodiment 2

[0036] refer to Figure 1-5, a kind of cosmetic raw material screening equipment, including an operation table 1, the top of the operation table 1 is slidably connected with a casing 2, the top of the casing 2 is welded with a feed hopper 3, and the inner wall of the casing 2 is welded with three filter plates 4 , the filter plate 4 forms a certain angle with the inner wall of the housing 2, and the two adjacent filter plates 4 are centrally symmetrical, the filter holes on the three filter plates 4 gradually decrease from top to bottom, and the Two and one discharge hoppers 5 are respectively welded on both sides, the discharge hopper 5 is matched with the corresponding filter plate 4, and the top of the console 1 is welded with two symmetrically arranged support seats 6, and the two support seats 6 are close to each other. There are two feed ports and one feed port 7 respectively on one side, the feed port 7 matches the corresponding discharge hopper 5, the top of the consol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com