Rapid cement bag breaking equipment for construction site

A construction site and bag breaking technology, which is applied in the field of cement rapid bag breaking equipment on construction sites, can solve problems such as troublesome operation, low work efficiency, and dust affecting the surrounding environment, and achieve the effect of not being easily injured

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

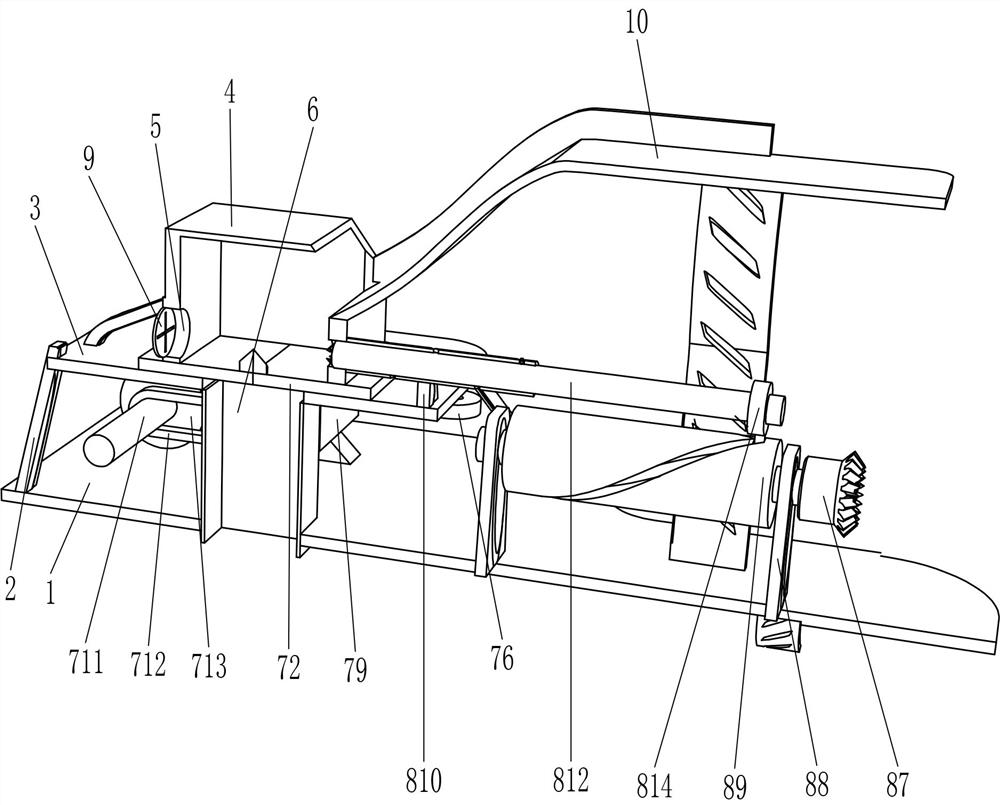

[0024] A kind of construction site cement quick breaking bag equipment, such as figure 1 , figure 2 , image 3 and Figure 5 As shown, it includes a base 1, a support bar 2, a guide plate 3, a discharge frame 4, a hopper 6, and a bag breaking mechanism 7. There are three support bars 2 fixedly connected to the right side of the top of the base 1, and between the tops of the three support bars 2 A guide plate 3 is fixedly connected, and a discharge frame 4 is fixedly connected to the top right side of the guide plate 3. The discharge frame 4 is located above the middle part of the guide plate 3. There is a bag-taking hole 5 in the middle of the lower part of the right side of the discharge frame 4. The guide plate The middle part of 3 is fixedly pierced with a discharge hopper 6, and the discharge hopper 6 also passes through the right side of the base 1, and a bag breaking mechanism 7 is provided between the guide plate 3 and the right side of the top of the base 1.

[002...

Embodiment 2

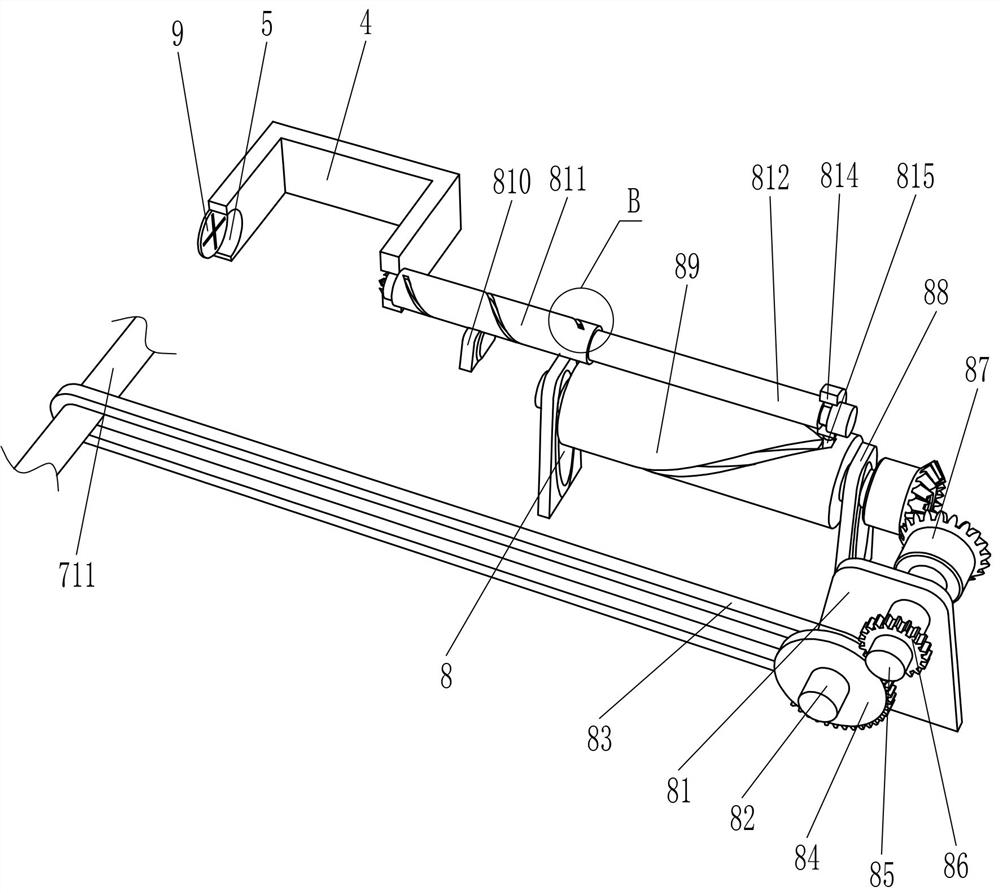

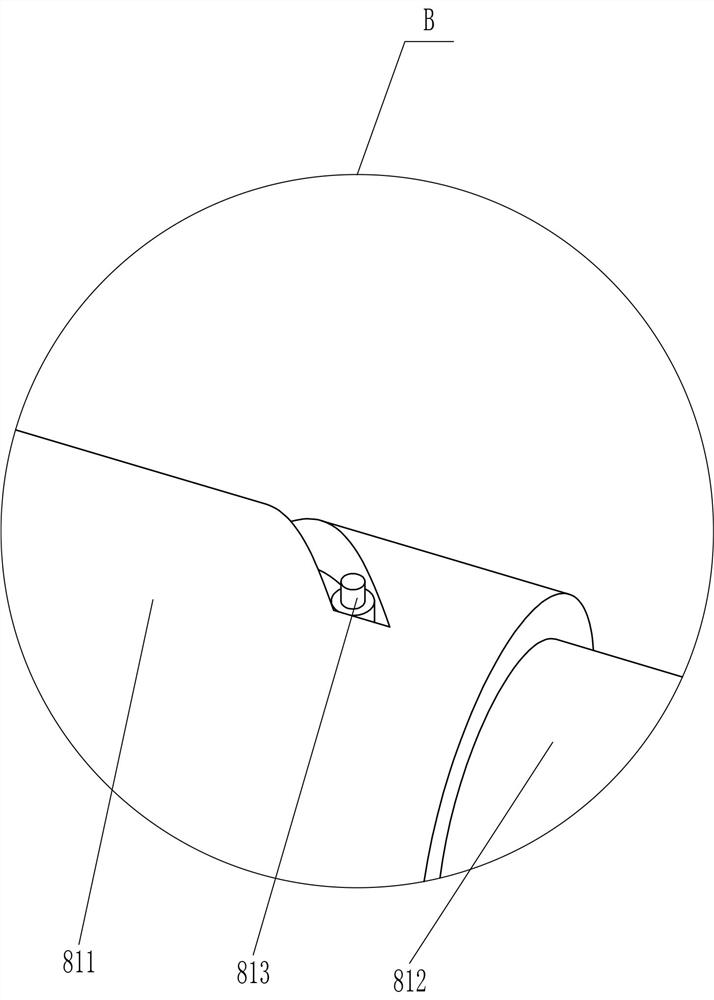

[0029] On the basis of Example 1, such as figure 1 , figure 2 , Figure 4 and Figure 6 Shown, also comprise rolling bag mechanism 8, rolling bag mechanism 8 comprises secondary transmission shaft 82, secondary belt 83, half gear 84, rotating shaft 85, cylindrical gear 86, bevel gear 87, support block 88, spiral groove post 89, Fixed block 810, spiral groove tube 811, rolling bag rod 812, runner rod 813, rotating ring 814 and latch 815, base 1 top left rear part is fixedly connected with supporting plate 81, supporting plate 81 bottom right rotating type is provided with Auxiliary transmission shaft 82, between the main transmission shaft 711 rear part and the auxiliary transmission shaft 82 middle part, a secondary belt 83 is wound around the pulley, the auxiliary transmission shaft 82 rear part is circumferentially fixed with a half gear 84, and the upper part of the support plate 81 is rotatably provided with Rotating shaft 85, the circumferential fixed sleeve of rotati...

Embodiment 3

[0032] On the basis of embodiment 1 and embodiment 2, such as figure 1 As shown, a dust-proof rubber plate 9 is also included, and the dust-proof rubber plate 9 is fixedly connected in the bag-taking hole 5, and the dust-proof rubber plate 9 cooperates with the bag roll bar 812.

[0033] Also includes a sliding material rack 10, the sliding material rack 10 is fixedly connected between the left side of the top of the base 1 and the inner and outer left sides of the discharging frame 4.

[0034] When the broken bag plate 72 moved outwards to break the cement bag, because of the effect of the dust-proof rubber plate 9, the dust of the cement was not easy to float out from the bag-taking hole 5. In this way, the dust of cement can be prevented from floating out from the bag-taking hole 5 and affecting the surrounding environment.

[0035] When the cement needs to be broken, the cement is placed on the slide frame 10, and the cement can slide into the discharge frame 4 through th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com