Center and surface winding slitter machine

A technology of slitting machine and winding mechanism, which is applied in the direction of winding strips, sending objects, thin material processing, etc. It can solve the problems that the original film cannot be separated, torn, etc., and the end surface of the finished product is straight and the film surface is not stretched. Stretch without wrinkle, high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

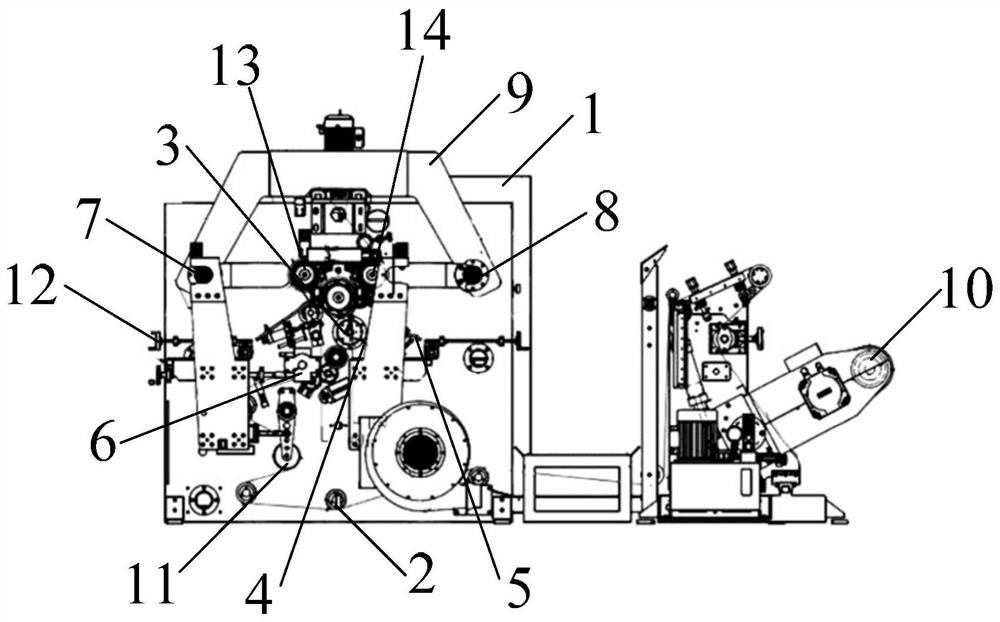

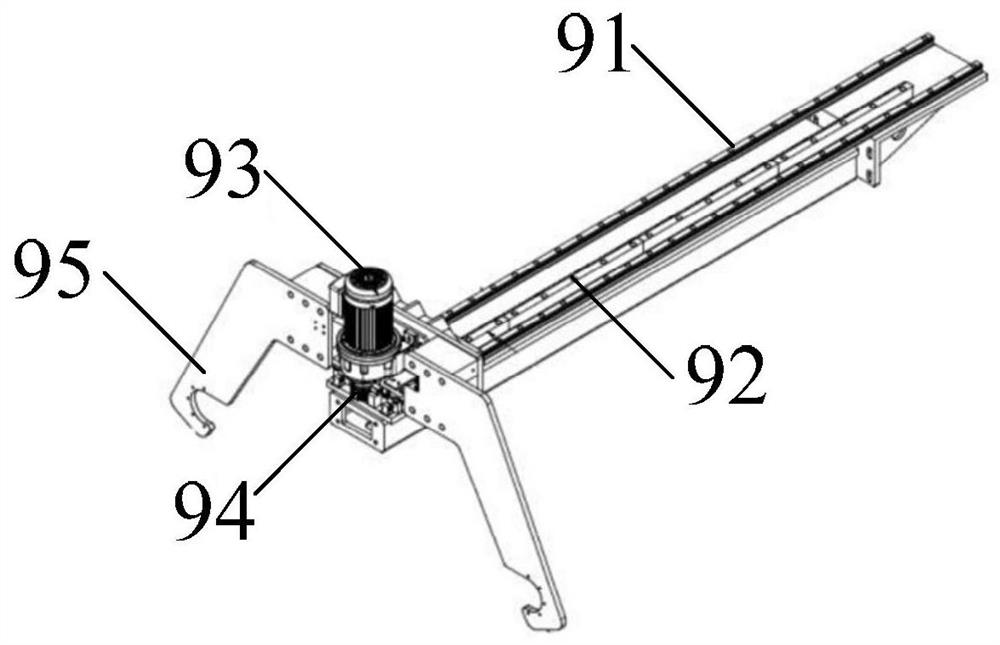

[0025] as attached figure 1 To attach figure 2 shown

[0026] The invention provides a center surface rewinding and slitting machine, comprising a rewinding seat 1, a transition aluminum wheel 2, an air shaft 3, a circular knife lower knife 4, a circular knife upper knife 5, a bow roller 6, and a first winding mechanism 7. The second winding mechanism 8, the pushing mechanism 9, the unwinding mechanism 10, the dancing wheel 11, the differential hand wheel 12, the tapered pulley 13 and the winding pressure roller 14, the unwinding mechanism 10 is installed on the One side of the seat 1; three transition aluminum wheels 2 are used, and the transition aluminum wheel 2 is installed under the front side of the receiving seat 1; the dancing wheel 11 is installed under the front side of the receiving seat 1 away from the end of the unwinding mechanism 10, And the dance wheel 11 is located above the transition aluminum wheel 2; the bow roller 6 is installed in the middle of the fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com