A positioning device and working method for installing a steel bar meter in an existing pile foundation borehole

A technology of positioning device and rebar gauge, which is applied in the direction of measuring device, mechanical measuring device, infrastructure engineering, etc., can solve the problems of wasting construction time, rebar gauge falling into borehole, consumption, etc., and achieve the effect of convenient coordination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

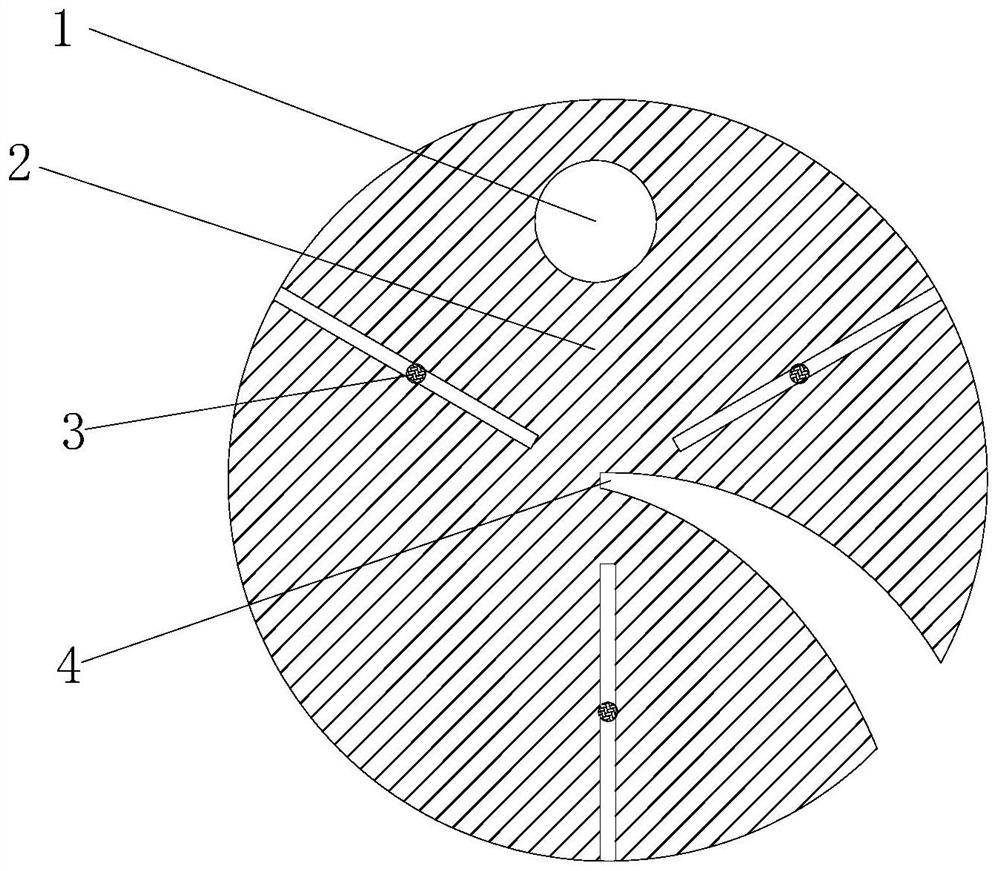

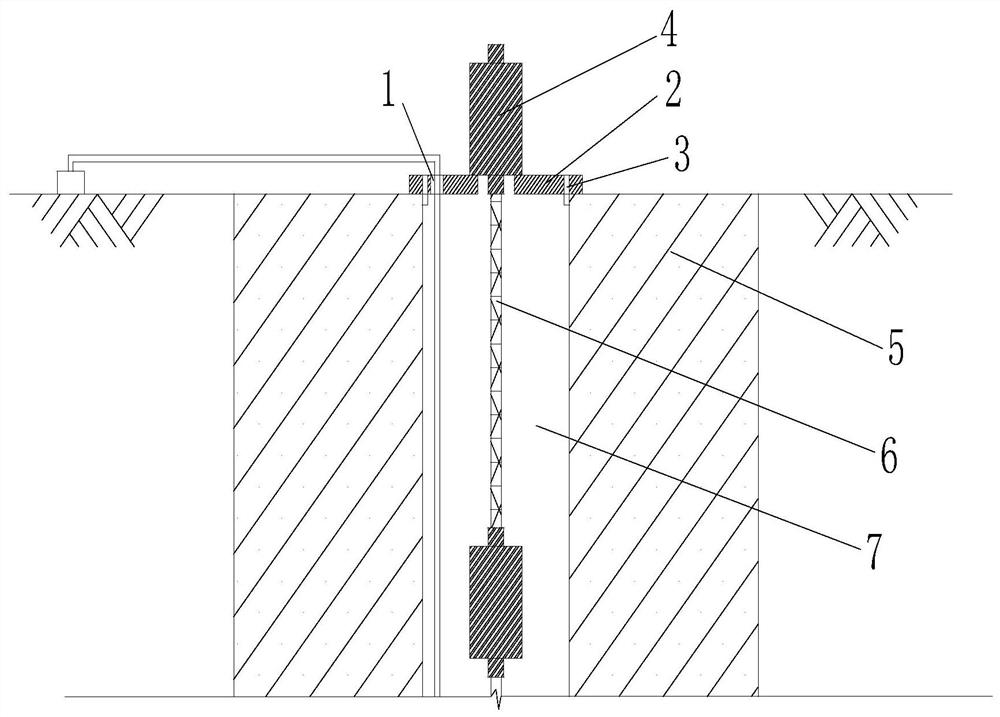

[0034] In a typical implementation of the present disclosure, such as Figure 1-Figure 2 As shown, a positioning device for installing a steel bar gauge in an existing pile foundation borehole is proposed.

[0035] It mainly includes the disc 2 and the positioning block 3 matching the disc. The disc is provided with a plurality of chutes for cooperating with the positioning block. The chute is distributed along the radial direction of the disc. The positioning block slides with the chute, and the positioning block is adjusted. The distance from the center of the disc, the positioning block presses against the inner wall of the drill hole, and the positioning block moves to push the disc to move to achieve the purpose of adjusting the position of the disc;

[0036] The chute is at least three, and the chute is distributed in different positions of the disc, and the chute corresponds to the positioning block one by one. In this embodiment, three chute are taken as an example, as...

Embodiment 2

[0057] In another typical embodiment of the present disclosure, a working method of a positioning device for installing a steel bar meter in an existing pile foundation borehole as in Embodiment 1 is given.

[0058] Include the following steps:

[0059] After the steel bar meter and the steel bar are connected through thread fit, they go down to the borehole of the existing pile foundation;

[0060] Arrange the disk, move the disk along the installation groove until the steel bar meter is stuck at the end of the installation groove, and the steel bar meter and the disk are distributed coaxially;

[0061] Support the disc at the opening of the drilled hole, adjust the position of the positioning block, and push the disc to change its relative position with the drilled hole until the reinforcement meter, steel bar and drilled hole are coaxially distributed.

[0062] The borehole 7 is in the center of the existing pile foundation 5, the diameter of the borehole 7 can be adjusted...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com