Connection device, discharge system and method

A technology for connecting equipment and connectors, applied in bridge construction, bridge parts, roads, etc., can solve cumbersome, time-consuming and other problems, and achieve the effect of avoiding cavities, low consumption, and low additional costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

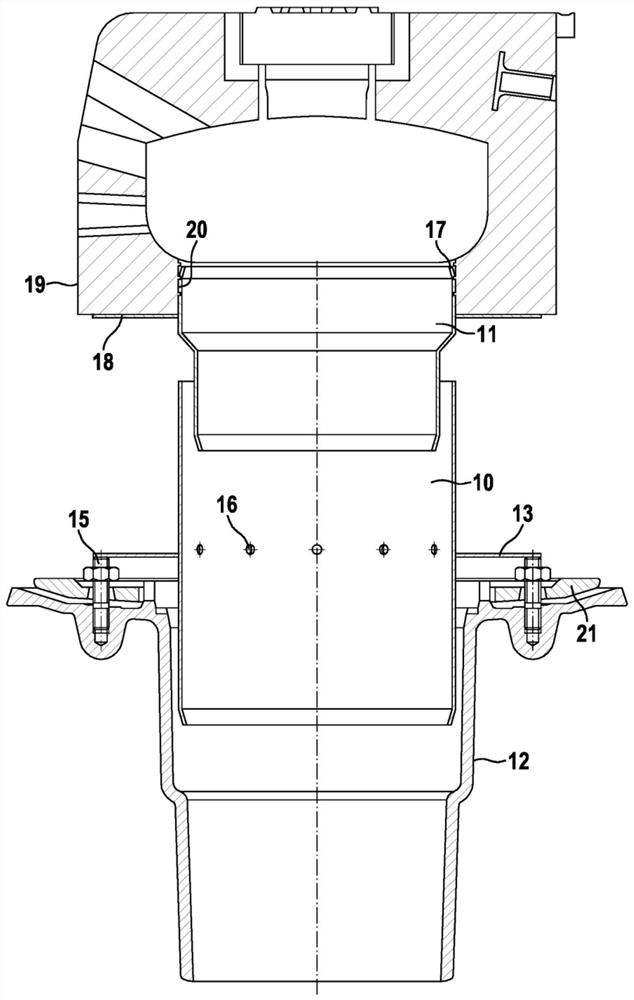

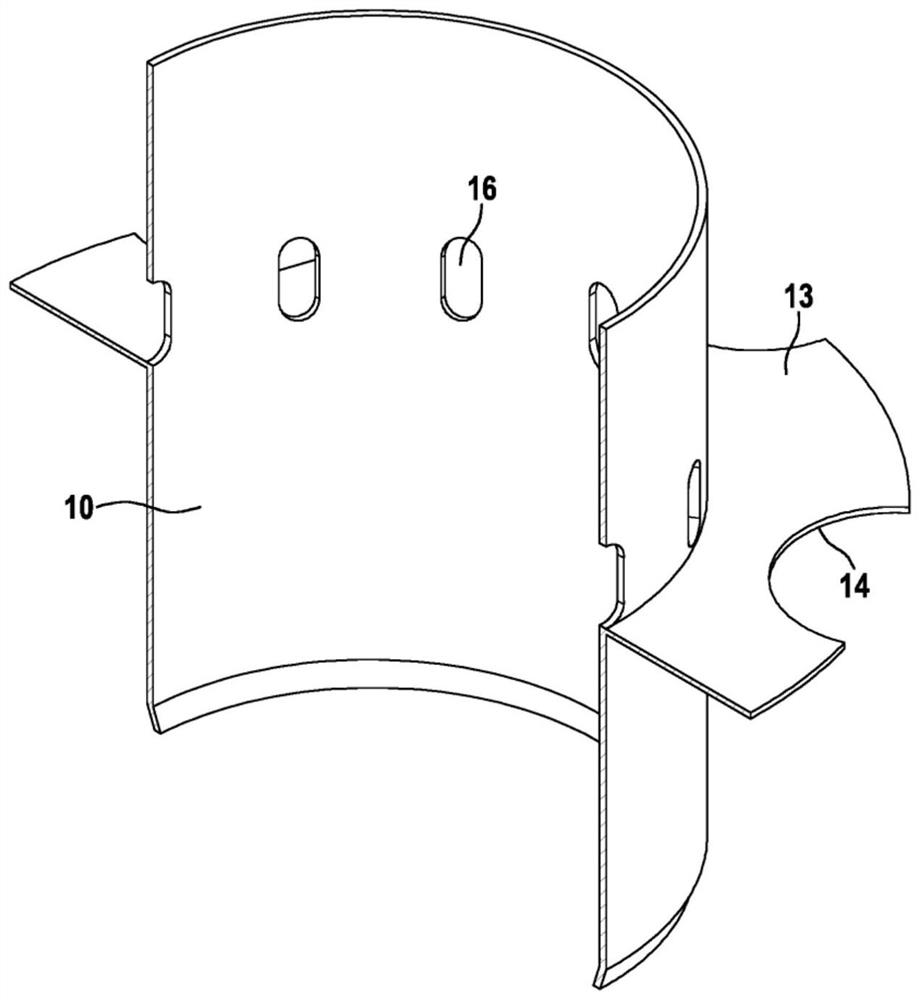

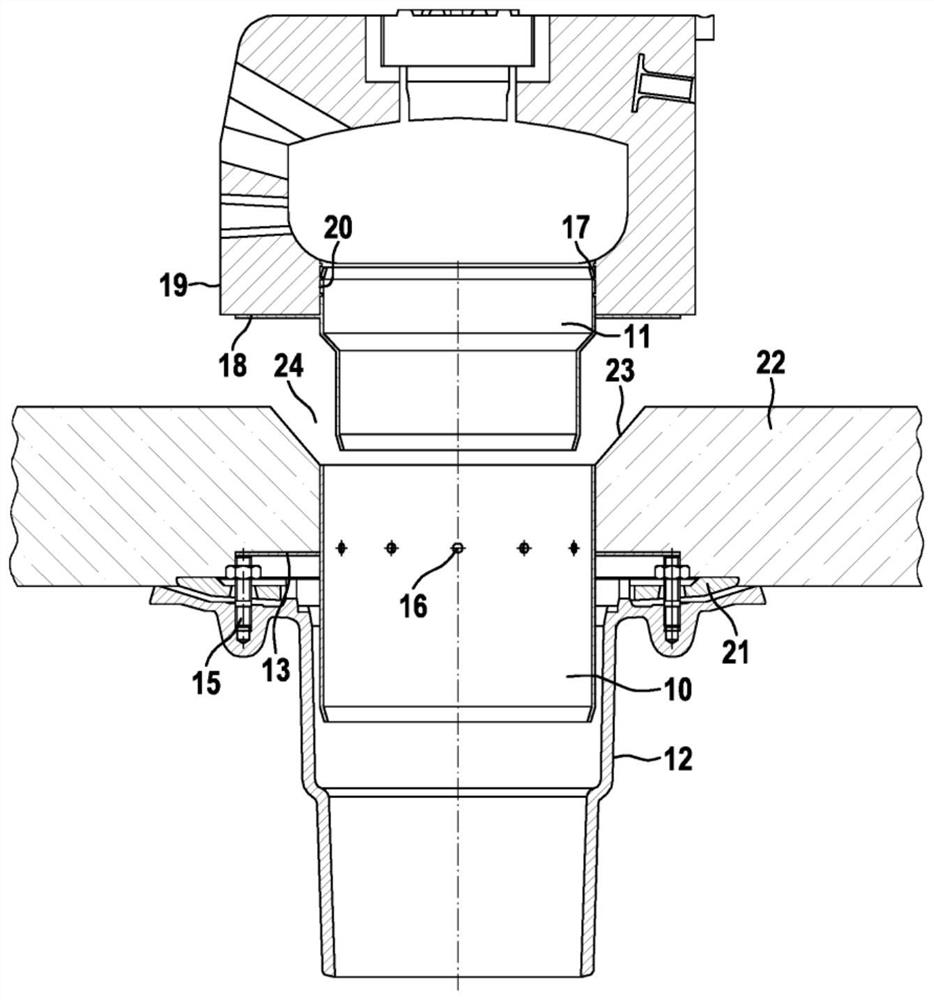

[0029] exist figure 1 shows the connected device with discharge system. The discharge body 12 is fastened in use by means of a compression flange 21 in a solid base, preferably concrete, and connected to the sewage network. The support flange 13 lies flat on the pressure flange 21 of the discharge body 12 . Optionally, the support flange 13 can have a cutout 14 for the screw connection 15 of the outlet body 12 , which cutout enables centering and delimitation of the axial rotation of the boot socket 10 .

[0030] The bearing flange 13 is located between the axial ends of the jacket socket 10 and extends partially into the outlet body 12 . Above the support flange 13 there can be drainage openings 16 on the section of the hood socket 10 that is in direct contact with the mortar, so that the draining Moisture is drawn away from the mortar. Attached to the exposed end of the hood socket 10 is an accessory socket 11 . The accessory socket has a flange 18 extending in the cir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com