Strip punch forming unit

A stamping forming and strip technology, applied in forming tools, perforating tools, feeding devices, etc., can solve the problems of time-consuming, laborious, low work efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] In order to make the purpose and advantages of the present application clearer, the present application will be specifically described below in conjunction with the embodiments. It should be understood that the following words are only used to describe one or several specific implementation modes of the application, and do not strictly limit the scope of protection specifically requested by the application. The features in the examples can be combined with each other.

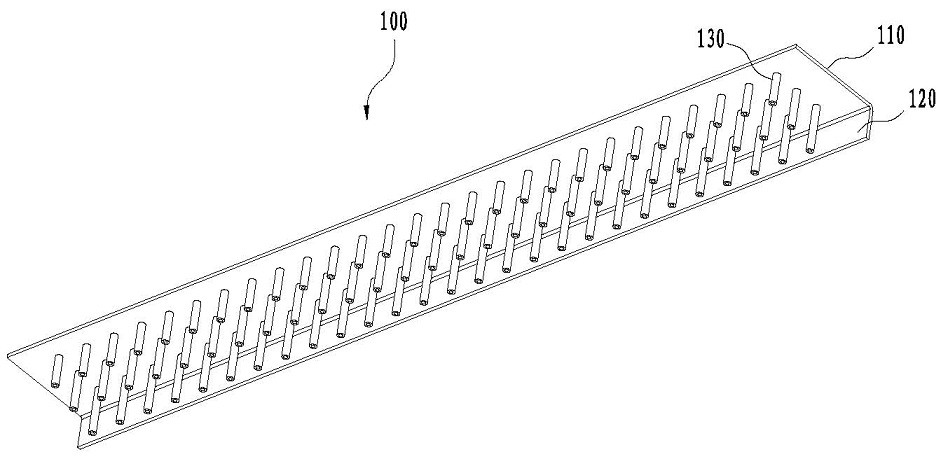

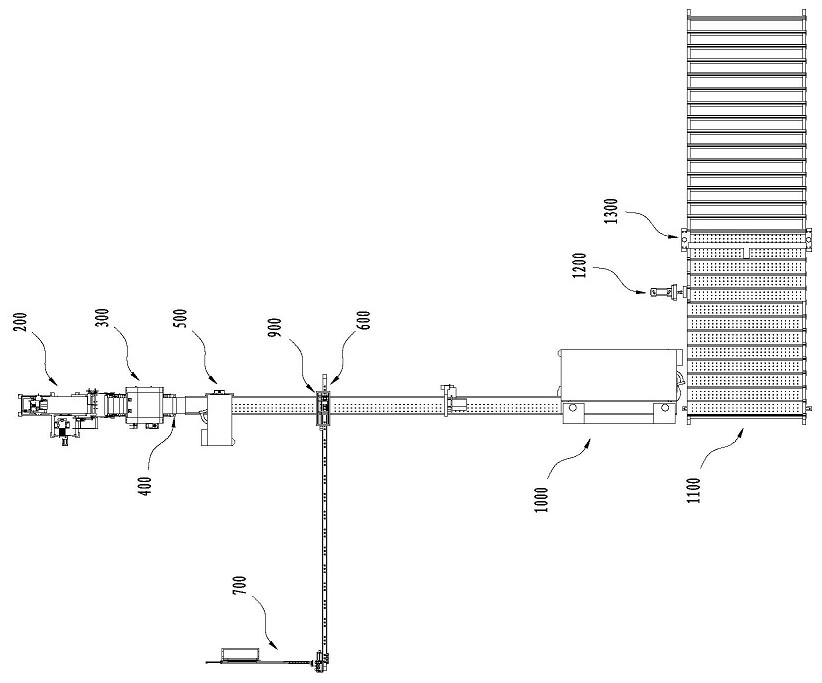

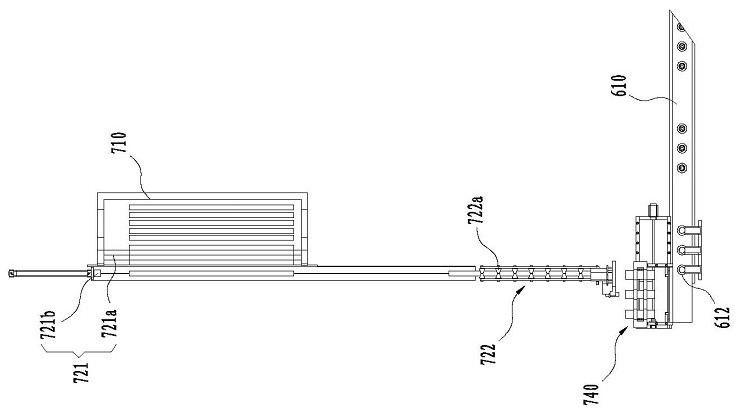

[0049] refer to Figure 1 to Figure 13 , the embodiment of the present application provides an automatic processing equipment for the air distribution board, including a punching mechanism 500 for punching the face 110 of the air duct plate on the board, and for inserting the end of the air distribution pipe 130 into the board The intubation mechanism 600 in the punched air distribution hole is used to weld the air distribution pipe 130 and the plate A welding mechanism 900, and the plate that has been ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com