Folding wing unfolding rotating shaft mechanism

A wing unfolding and rotating shaft technology, which is applied to the wing rotation of drones and the aviation field, can solve the problems of slow opening response speed, etc., and achieve the effect of reliable connection, simple connection method and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

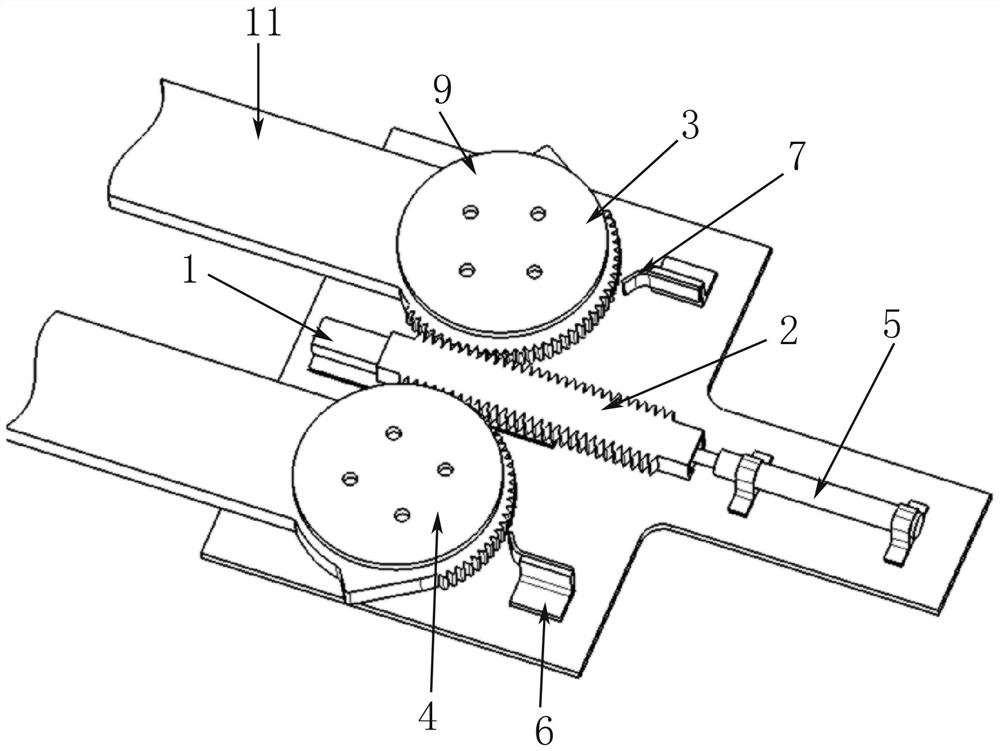

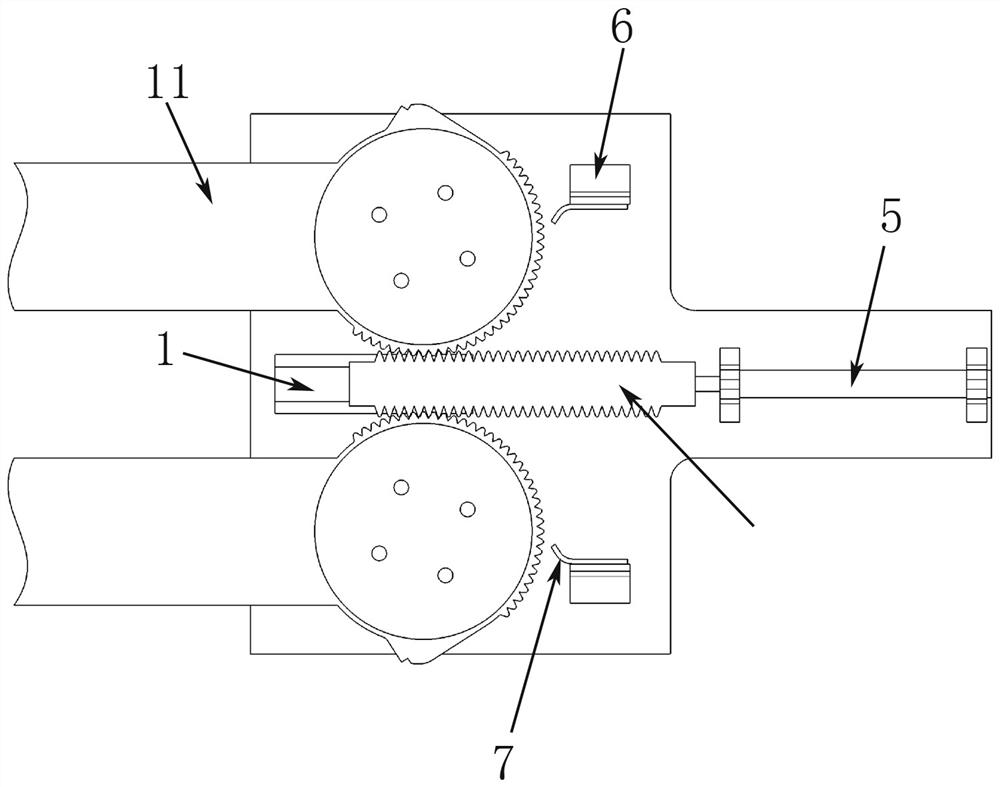

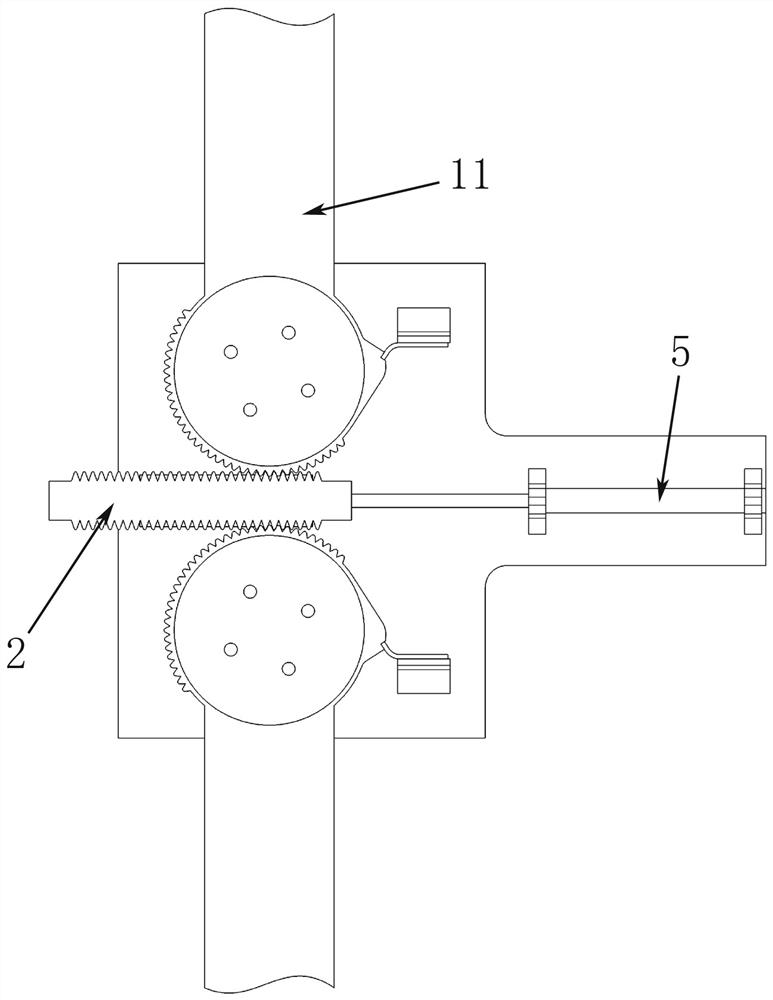

[0044] Such as figure 1 As mentioned above, the wing root 11 of the wing is an aluminum alloy machined part, and the left and right wings are respectively fixed on the connecting boss 10 of the connecting base, and fixed by the rotating shaft cover plate 9, and the rotating shaft cover plate 9 is protruded by the fixing bolt and the rotating shaft. station connection. Planar thrust needle roller bearings 8 are arranged between the lower end surface of the wing root 11 and the connecting base, and between the upper surface of the wing root 11 and the shaft cover 9 to ensure that the wing root 11 can rotate normally when the wing is subjected to lift.

[0045] In order to drive the wings to rotate and open, the first teeth are arranged on the arc length of the outer circle of the left and right wing roots 11 exceeding 1 / 4 of the circle. Between the two wing shafts, a rack 2 with teeth on both side walls of the wing root 11 is arranged, and the first tooth of the rack 2 meshes w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com