Modular mask socket capable of being hooked

A modular, face shield technology used in air handling equipment, aircraft parts, transportation and packaging to solve problems such as inability to detect installation and removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020]The present invention will be further described below with reference to the drawings and embodiments.

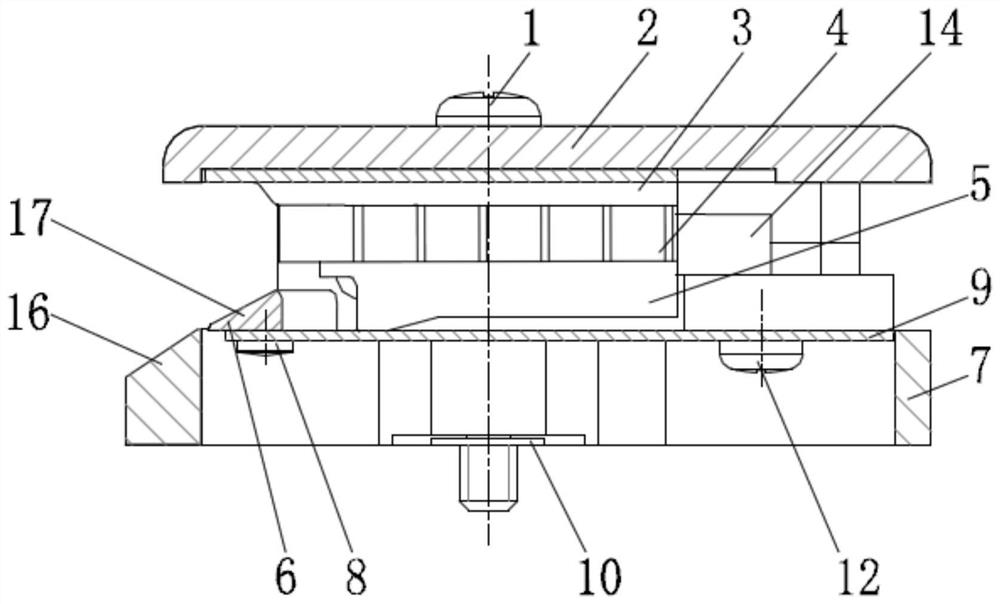

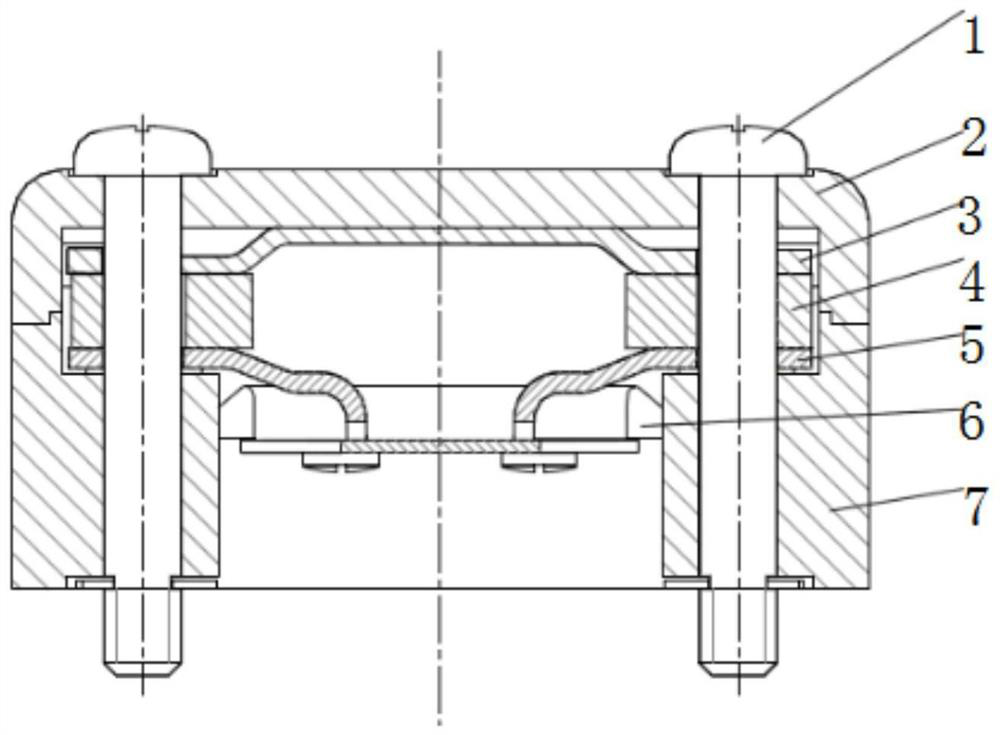

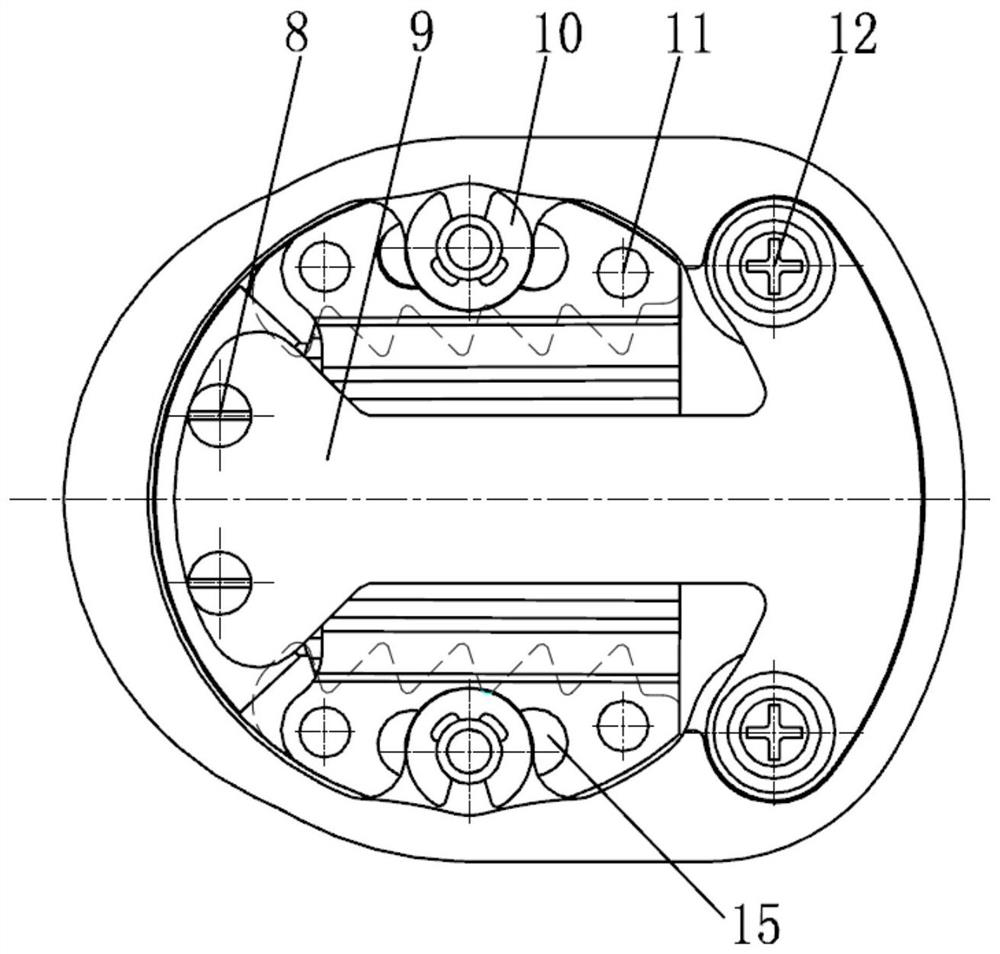

[0021]Such asFigure 1 to Figure 3As shown, a hookable modular mask socket is matched with a mask pin with a boss and a tooth, and includes a housing with a channel, and an upper plate 3 and a tooth are arranged in the channel from top to bottom. Strip 4, lower plate 5 and reed 9, upper plate 3 as a whole, rack 4 and lower plate 5 are distributed on both sides of the channel, upper plate 3, rack 4 and lower plate 5 are connected and fixed , The racks 4 on both sides can mesh with the clamping teeth, the upper plate 3 and the lower plate 5 can be attached to the clamping teeth, fixed shafts are provided on both sides of the upper channel of the housing, and the fixed shafts pass through the upper plate 3 on the corresponding side , The arc grooves on the rack 4 and the lower plate 5, the upper plate 3, the rack 4 and the lower plate 5 can rotate around the fixed axis through the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com