Glass composition and chemically strengthened glass

A glass composition and molar percentage technology, applied in the field of chemically strengthened glass, can solve problems such as low impact, achieve the effects of excellent scratch resistance and pressure resistance, good mechanical properties, and reduce the possibility of protection failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0108] In order to further clearly illustrate and illustrate the technical solution of the present invention, the following non-limiting examples are provided.

[0109]

[0110] The present invention adopts the manufacturing method of the above-mentioned glass composition to obtain the glass composition having the compositions shown in Table 1-Table 3. In addition, the characteristics of each glass composition were measured by the test method described in the present invention, and the test results are shown in Tables 1 to 3.

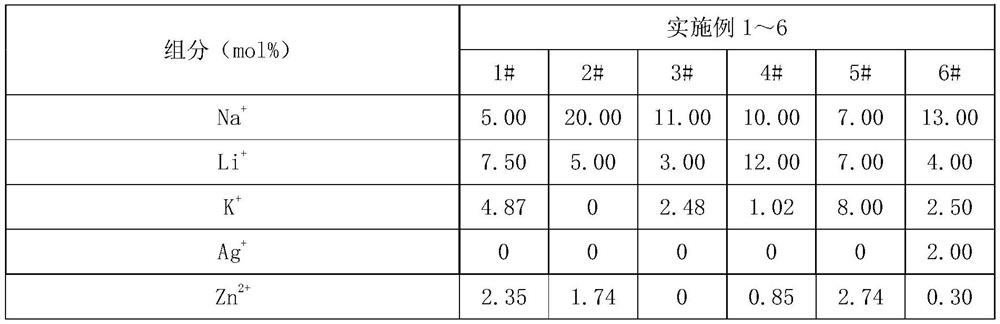

[0111] Table 1.

[0112]

[0113]

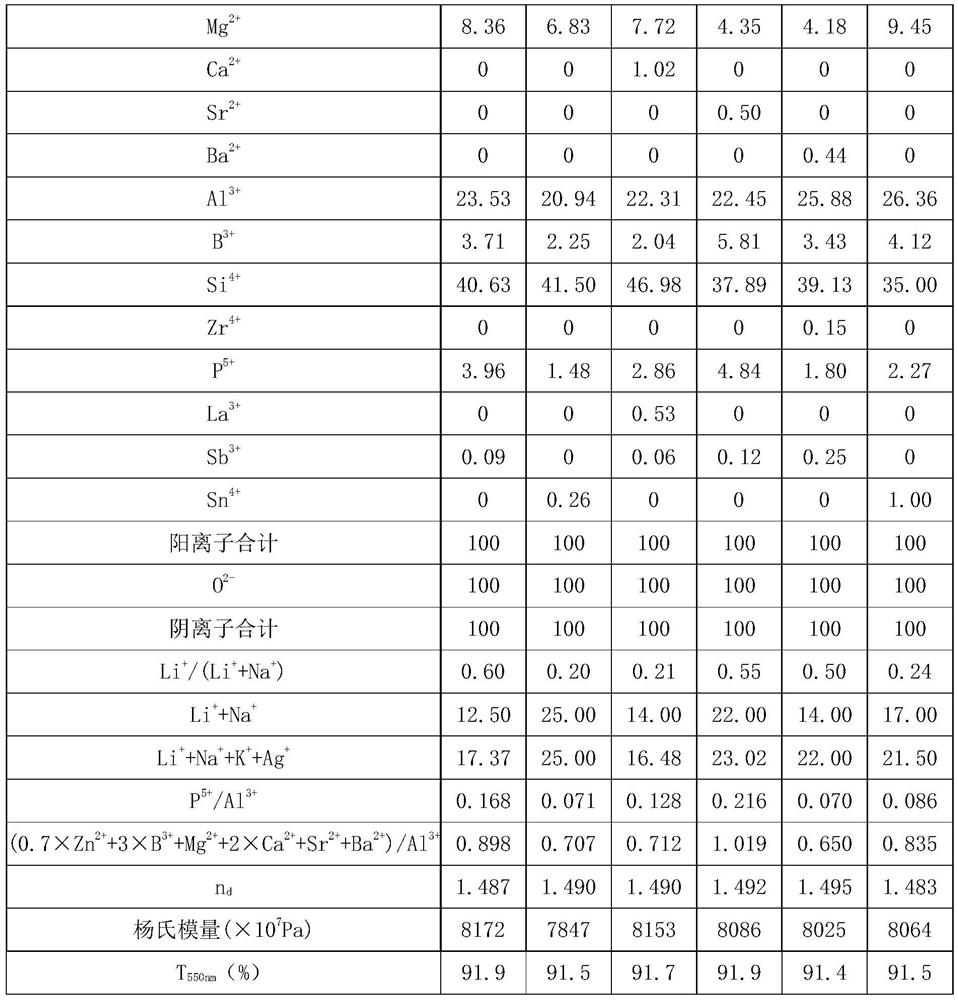

[0114] Table 2.

[0115]

[0116]

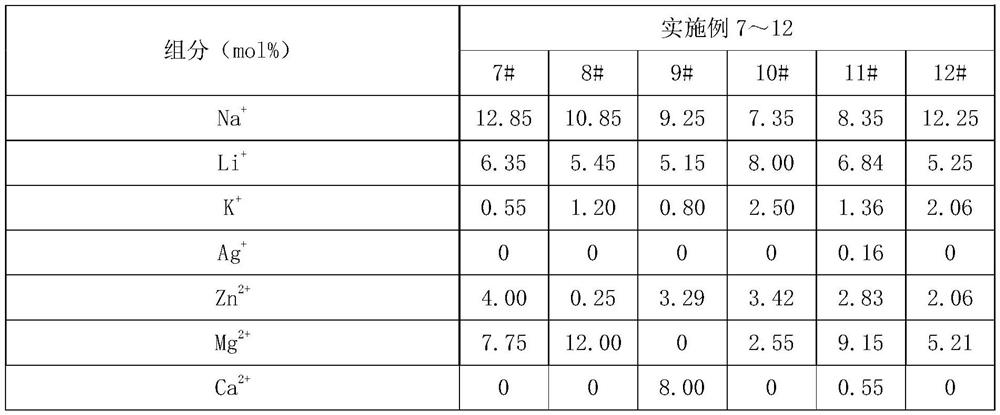

[0117] table 3.

[0118]

[0119]

[0120]

[0121] Using the glass compositions shown in Tables 1 to 3, chemically strengthened glass was produced by the method for producing chemically strengthened glass, and the chemical strengthening process is shown in Tables 4 to 8. In addition, the micro-Vickers hardness of each chemically strengthened glass was measu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com