Guide claw release mechanism internally provided with transmission shaft

A release mechanism and transmission shaft technology, applied in wellbore/well parts, earthwork drilling and production, etc., can solve the problems that the transmission shaft cannot be arranged in the center, takes up a lot of space for the instrument, and has a large volume, so as to achieve quick start, high acceptance, and Ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

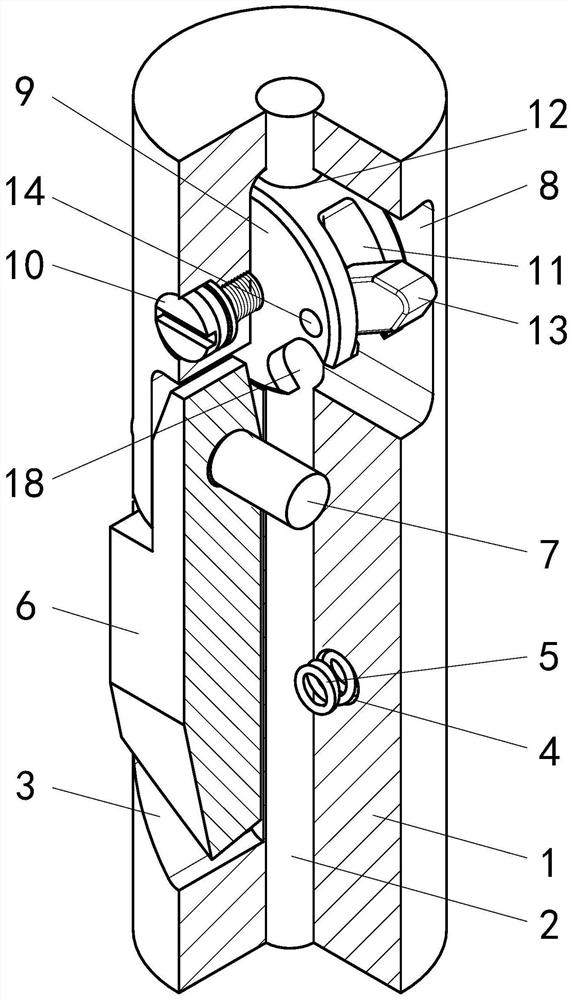

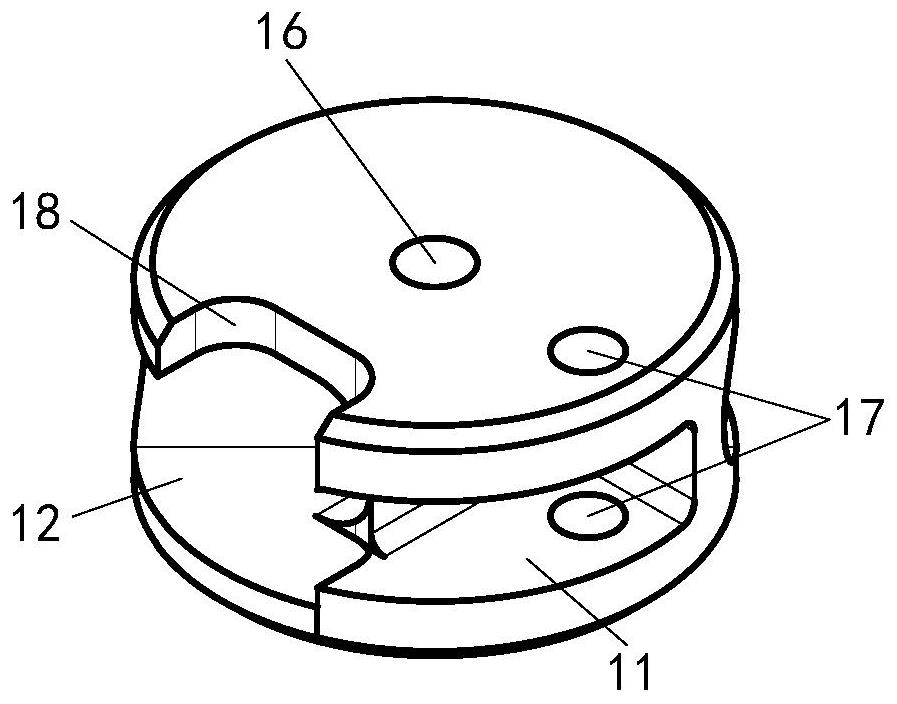

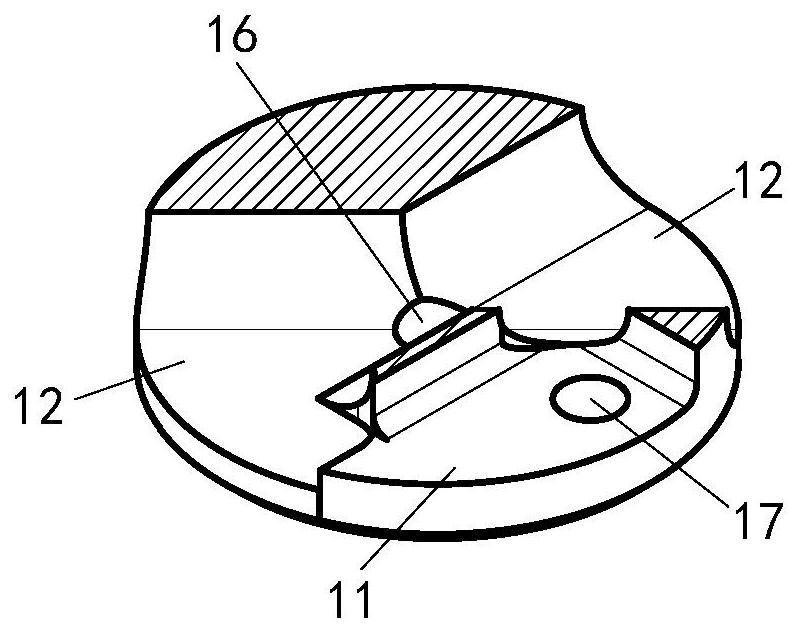

[0021] A kind of guiding pawl release mechanism that is provided with transmission shaft inside the present invention, as Figure 1 to Figure 7 As shown, it includes a cylindrical base 1; the central hole 23 of the cylindrical base 1 is provided with a transmission shaft 2, and the base 1 on one side of the transmission shaft 2 is provided with a guide claw groove 3, and the bottom of the guide claw groove 3 is provided with a spring hole 4. The spring hole 4 is provided with a spring 5; the guide claw groove 3 is provided with a guide claw 6; the guide claw 6 is hinged with the cylindrical base 1 through the guide claw pin 7; The cam groove 8 is provided with a cam 9; the cam 9 is connected to the cylindrical base 1 by a fixed angle through a pair of cam screws 10; the cam 9 is provided with a collision switch groove 11 and a transmission sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com