Process for decomposing biomass into micromolecular gas by directional thermochemical conversion

A process method and thermochemical conversion technology, which is applied in the field of efficient and clean conversion of renewable biomass into clean energy, can solve problems that consume a lot of time, energy and money, and affect the regularity analysis of results, etc., to achieve fast and practical High value and universal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

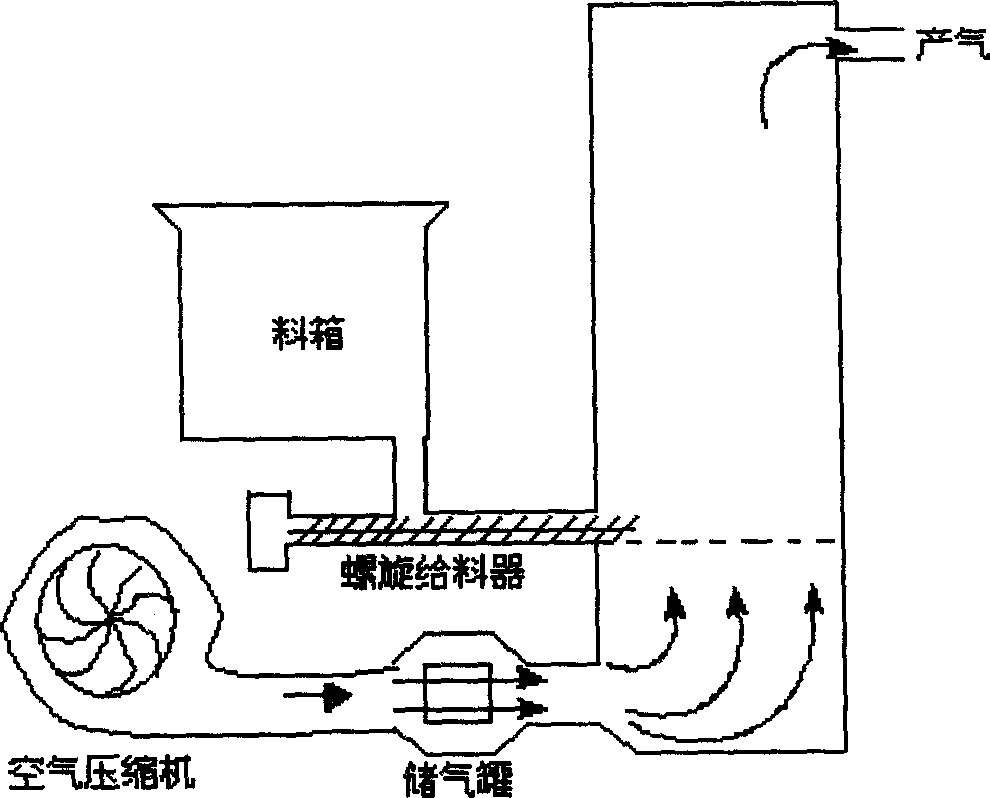

[0041] For burning sawdust, 100 kg per hour is passed into the fluidized bed gasifier with a water content of 10%, then 24 liters / hour of air and 240 kg / hour of water vapor are passed into the gasifier, so that the combustion temperature in the gasifier reaches 800 degrees Celsius, and the production The calorific value of the gas is about 3.6 MJ / m3, and the ratio of hydrogen to carbon monoxide in the produced gas reaches 2:1, which meets the requirements of catalytic synthesis. Through this method, directional gasification can be realized.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com