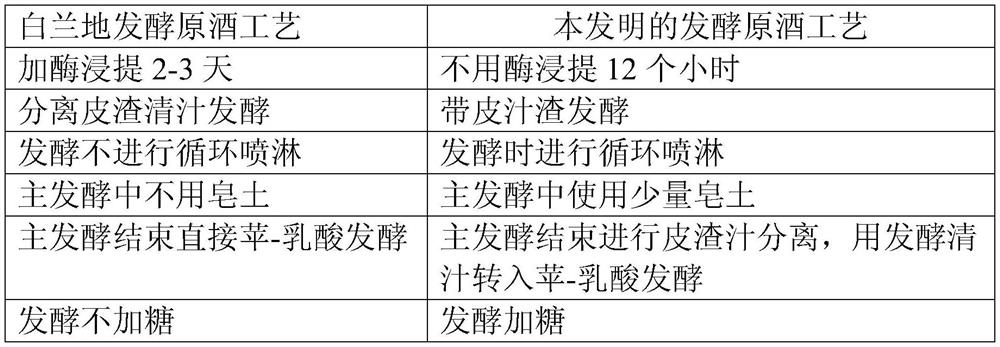

Grape spirits raw wine production process

A production process and grape technology, applied in the field of wine production process, can solve the problems of poor quality of grape spirits, strong pungent smell, high internal control index, etc., and achieve the effect of obvious quality preservation and stability, less residual sugar, and thorough fermentation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

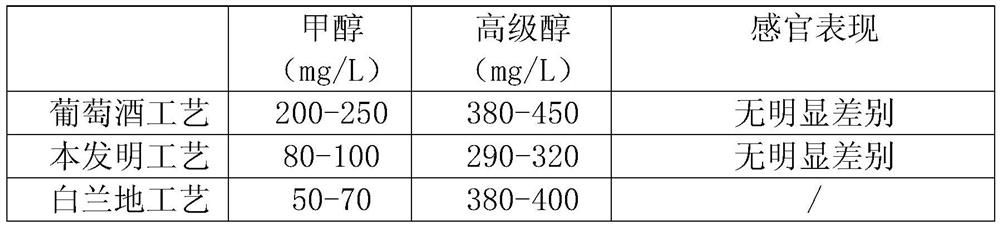

Examples

Embodiment 1

[0043] A kind of raw wine production process of grape spirits, the process steps are as follows:

[0044] (1) Adopt the fully ripe crystal grapes picked on the same day, remove the grape fruit stems, and crush to obtain the crushed grape pulp. The crystal grape, also known as Niagara grape (Niagara Grape), originates in America and is now widely planted in Yunnan Province of my country.

[0045] (2) Cool the crushed grape pulp to below 18°C, soak it naturally for 12 hours, and spray it circularly during the dipping. on the pulp, so that the grape marc is fully fused to obtain the grape marc mash. Sprinklers with pumps can be purchased commercially, or can be made by themselves according to the prior art.

[0046] (3) Add grape fermenting active dry yeast FC9 to the grape must mash body, add bentonite diluent that has been expanded simultaneously, fully mix with the grape must mash body, obtain the grape must mash mixture; grape fermentation The amount of active dry yeast FC...

Embodiment 2

[0053] A kind of raw wine production process of grape spirits, the process steps are as follows:

[0054] (1) Adopt the fully ripe crystal grapes picked on the same day, remove the grape fruit stems, and crush to obtain the crushed grape pulp.

[0055] (2) Cooling the crushed grape pulp to below 18°C, soaking it naturally for 12 hours, and circulating spraying during the soaking period, so that the grape juice marcs are fully fused, and the grape juice marc mash is obtained.

[0056] (3) Add grape fermenting active dry yeast FC9 to the grape must mash body, add bentonite diluent that has been expanded simultaneously, fully mix with the grape must mash body, obtain the grape must mash mixture; grape fermentation The amount of active dry yeast FC9 added is 0.15‰ of the mass of grape marc mash, and the amount of bentonite dilution is 0.2‰ of the mass of grape marc mash.

[0057] (4) Put the grape juice dregs mash mixture in the fermenter, carry out the main fermentation under th...

Embodiment 3

[0063] A kind of raw wine production process of grape spirits, the process steps are as follows:

[0064] (1) Adopt the fully ripe crystal grapes picked on the same day, remove the grape fruit stems, and crush to obtain the crushed grape pulp.

[0065] (2) Cooling the crushed grape pulp to below 18°C, soaking it naturally for 12 hours, and circulating spraying during the soaking period, so that the grape juice marcs are fully fused, and the grape juice marc mash is obtained.

[0066] (3) Add grape fermenting active dry yeast FC9 to the grape must mash body, add bentonite diluent that has been expanded simultaneously, fully mix with the grape must mash body, obtain the grape must mash mixture; grape fermentation The addition amount of active dry yeast FC9 is 0.2‰ of the mass of grape marc mash, and the addition amount of bentonite diluent is 0.4‰ of the mass of grape marc mash.

[0067] (4) Put the grape juice dregs mash mixture in the fermenter, carry out the main fermentatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com