Laminated battery

A laminated, battery technology, used in secondary batteries, secondary battery manufacturing, battery pack components, etc., can solve the problem of damage to the insulating coating layer, pinholes in the insulating coating layer, electrode plates and external packaging. Short circuit and other problems, to achieve the effect of improving reliability, suppressing capacity reduction, and preventing short circuit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

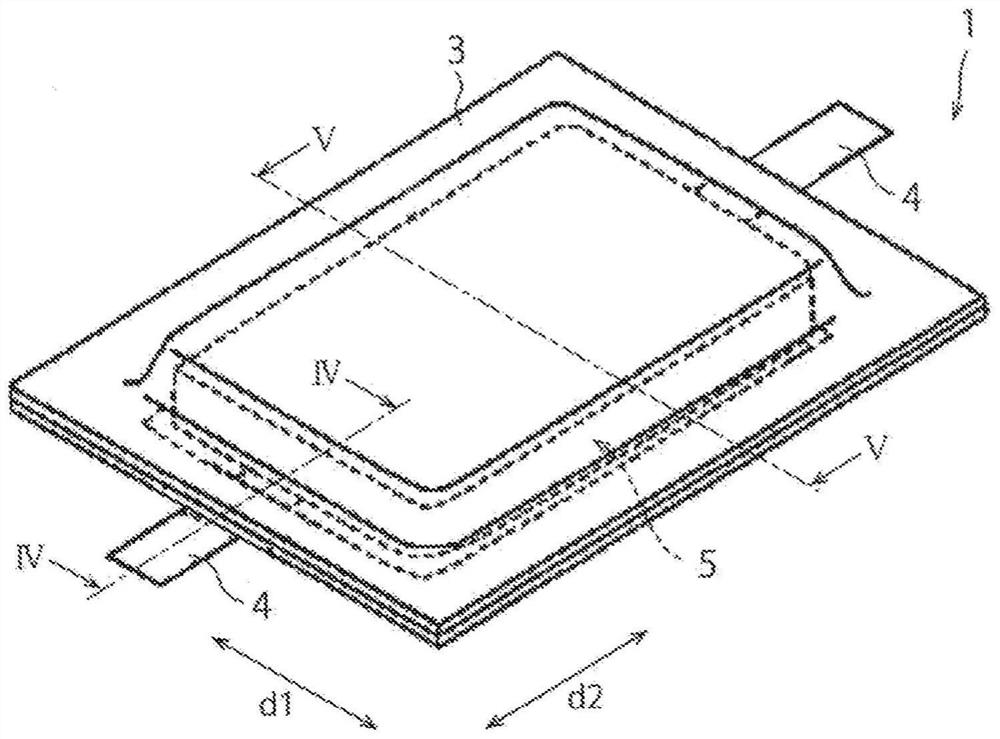

[0096] Figure 1 to Figure 8 It is a figure for demonstrating the 1st Embodiment of the laminated electrode based on 1st invention. figure 1 is a perspective view showing a specific example of a laminated battery. Such as figure 1 As shown, the laminated battery 1 has: an outer packaging body 3, a membrane electrode assembly 5 accommodated in the outer packaging body 3, and a wire connected to the membrane electrode assembly 5 and protruding from the inside of the outer packaging body 3 to the outside. slice 4. Such as figure 2 As shown, the membrane electrode assembly 5 has first electrode sheets 10 and second electrode sheets 20 alternately stacked. figure 1 In the example shown, the laminated battery 1 has an overall flat shape extending along a first direction d1 as a width direction and a second direction d2 as a length direction.

[0097] Hereinafter, description will be made by taking the stacked battery 1 as an example to constitute a lithium ion secondary batter...

no. 2 Embodiment approach

[0163] Figure 9 to Figure 16 It is a figure for demonstrating the 2nd Embodiment of the laminated electrode based on 2nd invention.

[0164] In the second embodiment described below, the laminated battery 101 has an outer package 140 , a membrane electrode assembly 105 accommodated in the outer package 140 , and a The lug 103 protruding outward. Among them, the membrane electrode assembly 105 has first electrode plates 110 and second electrode plates 120 stacked alternately, and an insulator 130 located between the first electrode plates 110 and the second electrode plates 120 . In such a laminated battery 101, in the manufacture of the plurality of electrode plates 110, 120 constituting the membrane-electrode assembly 105, the electrode plates 110 may be damaged due to the decrease in positioning accuracy and the positional displacement of the electrode plates 110, 120 during use. , 120 and the external packaging body 140 are short-circuited. The laminated battery 101 in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com