Tobacco lamina selection process

A cigarette and process technology, applied in the field of cigarettes, can solve the problems of manual selection and crushing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solution of the present invention is described in detail below through the examples, and the following examples are only exemplary and can only be used to explain and illustrate the technical solution of the present invention, rather than being interpreted as a limitation to the technical solution of the present invention.

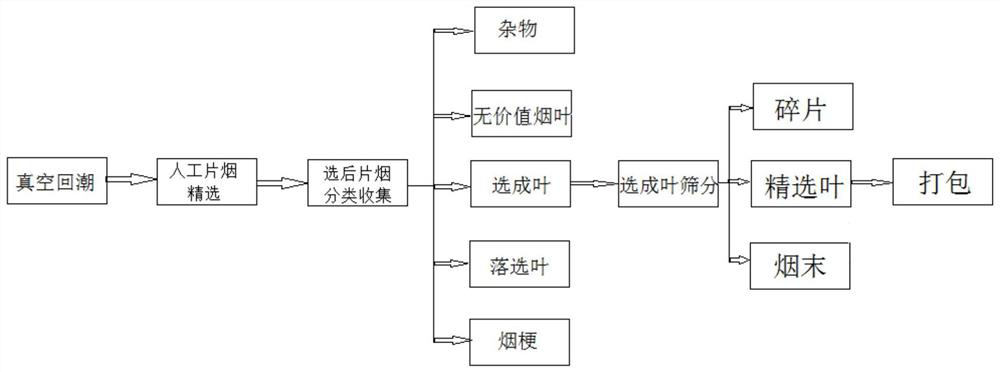

[0023] Such as figure 1 As shown, the application provides a kind of sheet tobacco selection process, comprising the following steps:

[0024] Vacuum regain:

[0025] First, unpack the selected grade (module) (200 kg / box) and divide it into 3 pieces for vacuum moisture resurfacing. Moisturizing technical parameters: working vacuum degree is 300pa; working steam pressure > 0.8Mpa; working positive air consumption is 1450kg / h; cooling water temperature 0.5Mpa, after vacuum moisture resurfacing, the moisture content of general tobacco leaves can reach 15 —16%.

[0026] Piano selection:

[0027] The temperature and humidity setting of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com