Self-dewatering stable buoyancy tank

A stable, buoyant tank technology, applied to floating buildings, using auxiliary nozzles or propellers to reduce ship movement, etc., can solve the problems of low stability of buoyant tanks, achieve high safety, moderate impact, and ensure stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

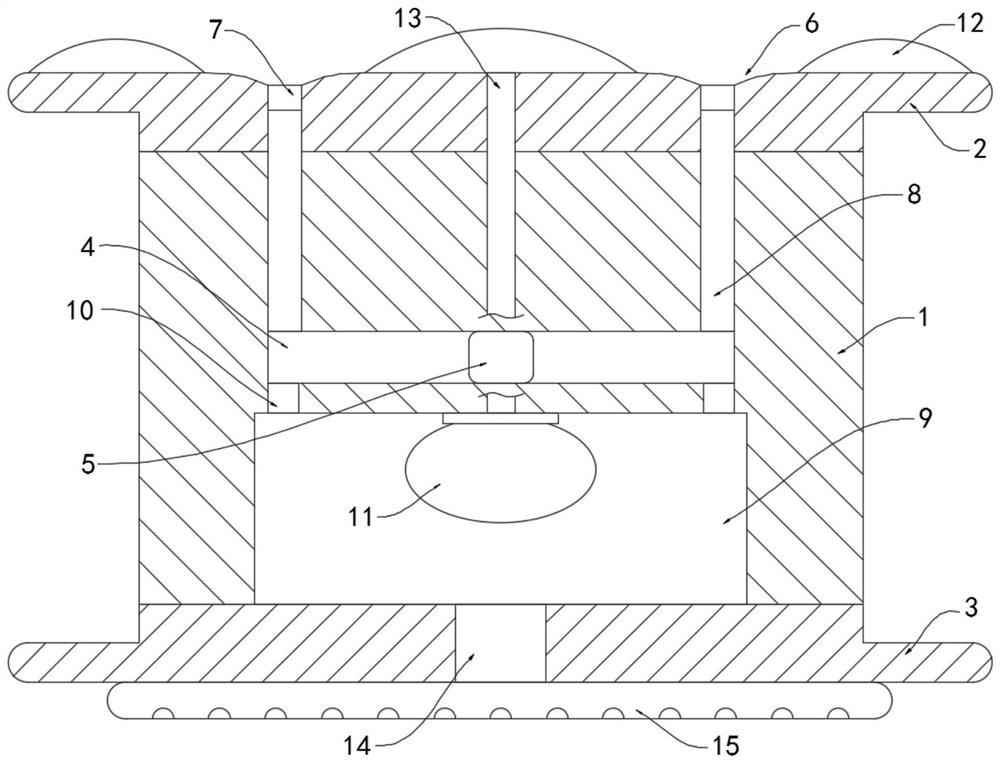

[0024] Such as Figure 1-2 Shown, a kind of self-removing water-type stable type buoyant tank comprises box body 1, and the upper and lower sidewalls of box body 1 are respectively fixedly connected with upper connection block 2 and lower connection block 3, above is the prior art, will not do it here Too much to repeat.

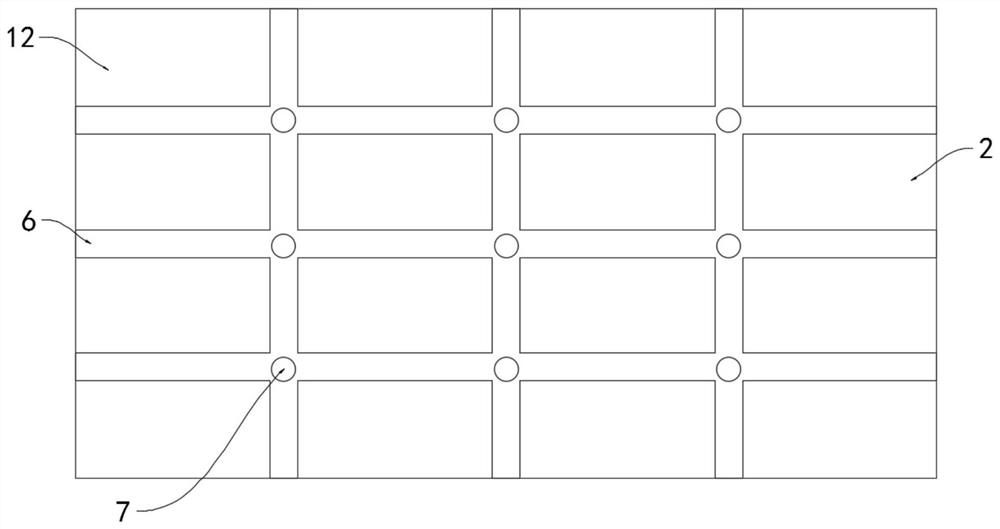

[0025] The interior of the box body 1 is provided with a sliding chamber 4 arranged horizontally, and the sliding block 5 is slidably connected to the sliding chamber 4. The upper side wall of the box body 1 is provided with a plurality of staggered water collection grooves 6, and the intersection of the plurality of water collection grooves 6 are equipped with drainage holes 7 (such as figure 2 shown), it is worth mentioning that the orifices of a plurality of drainage holes 7 are all lower than the bottom of the sump 6 (such as figure 1 Shown), the water in the sump 6 is accumulated to the orifice of the drain hole 7.

[0026] A plurality of drainage h...

Embodiment 2

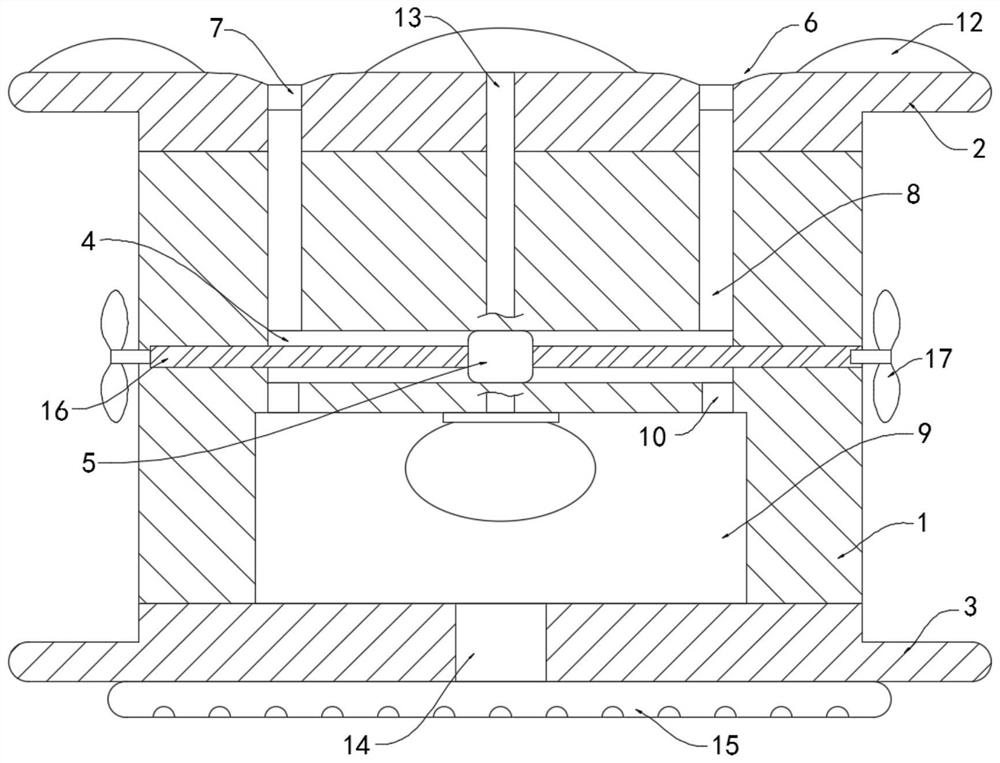

[0035] Such as image 3 As shown, the difference between this embodiment and Embodiment 1 is that the sliding chamber 4 is provided with a threaded rod 16 coaxially arranged with the sliding chamber 4, and the threaded rod 16 is arranged through the sliding block 5 and is connected with the screw thread on the outer wall. The sliding block 5 is threaded. It should be noted that the cross section of the sliding chamber 4 is rectangular, which can limit the sliding block 5, thereby driving the threaded rod 16 to rotate during the sliding process of the sliding block 5 .

[0036] Both ends of the threaded rod 16 extend to the inside of the casing 1 and are rotatably connected to the casing 1. Two push fans 17 are arranged outside the casing 1, and the rotating shaft of each push fan 17 extends to the inside of the casing 1 and is connected to the casing 1. It is fixedly connected with the end of the threaded rod 16 .

[0037] In this embodiment, when the wind and waves are relat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com