Ball screw type eddy current damper with negative-stiffness nonlinear energy trap

A non-linear energy trap and eddy current damper technology, applied in the field of structural vibration reduction, can solve the problem of magnetic leakage of the eddy current damper that has not been solved, and achieve a convenient modular assembly, good robustness, and wide control frequency band. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

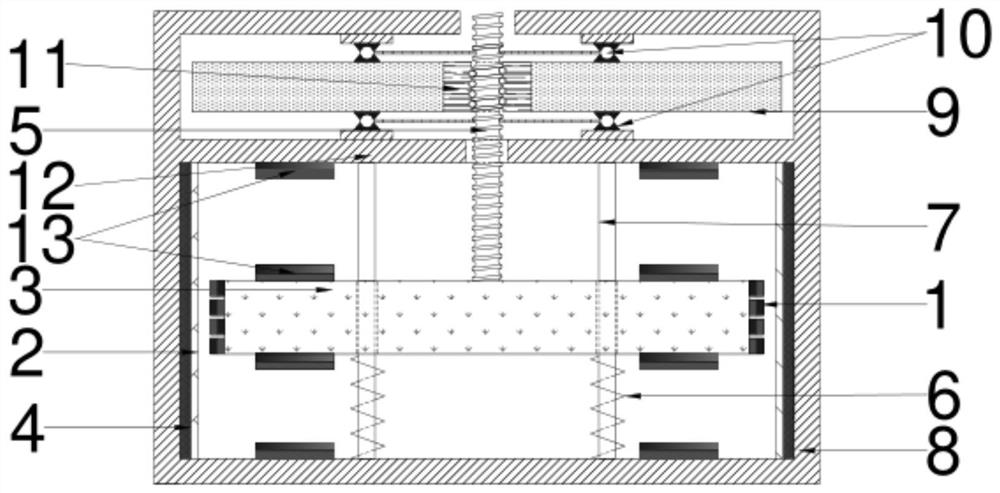

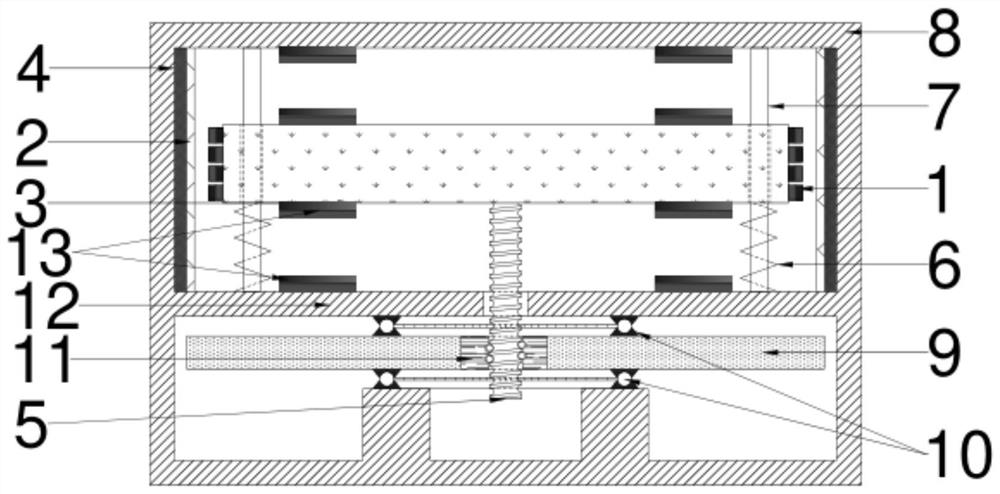

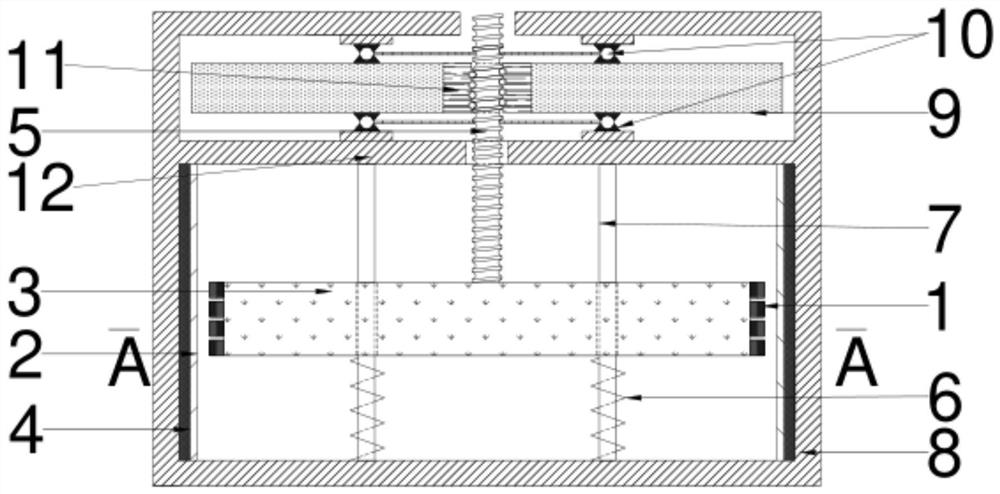

[0047] This embodiment discloses a vertically tuned mass ball screw type inertial eddy current damper with negative stiffness nonlinear energy well, such as Figure 1 to Figure 6 As shown, the support frame 12 divides the outer frame 8 into two layers; The top and bottom surfaces of the lower layer are affixed. The mass block 3 is slidably sleeved on the guide rod 7; the free end of the spring 6 is fixedly connected to the mass block 3, and the fixed end of the spring 6 is connected to the support frame 12 or the outer frame 8 fixed connection. The iron plate 4 is attached to the inner wall surface of the upper or lower layer where the mass block 3 is located; the conductor plate 2 is attached to the surface of the iron plate 4; the alternating permanent magnet group 1 is arranged on the The vertical side of the mass block 3, and there is a set gap between the alternating permanent magnet group 1 and the conductor plate 2. The ball screw 5 is vertically arranged, and the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com