Assembly type floor veneer integrated board convenient to hoist

A floor slab, prefabricated technology, applied in the direction of floor slab, transportation and packaging, load hanging components, etc., can solve the problems of affecting installation efficiency, unable to adjust the position of the lifting ring, unable to meet the lifting and installation requirements, etc., to simplify the connection steps, The effect of improving installation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

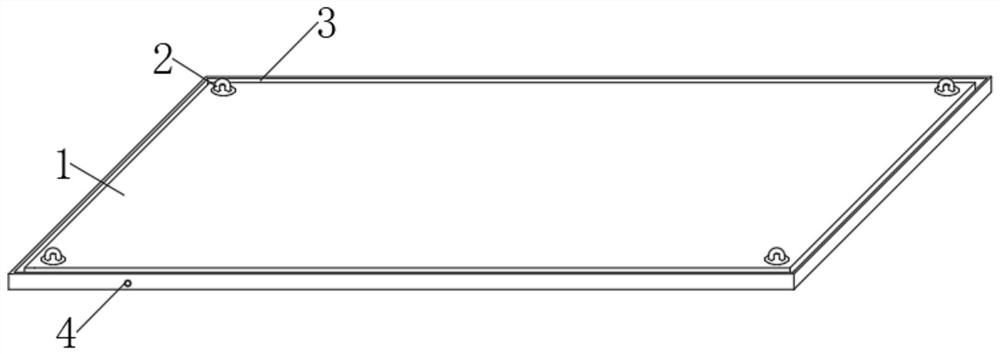

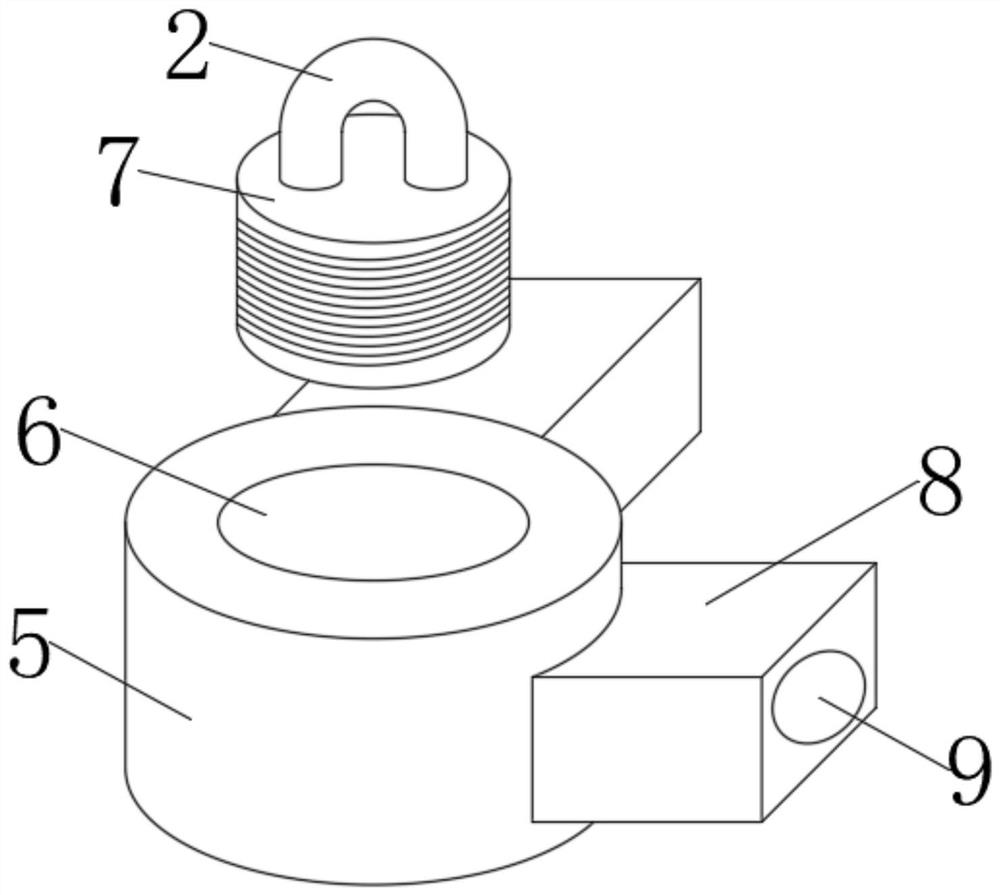

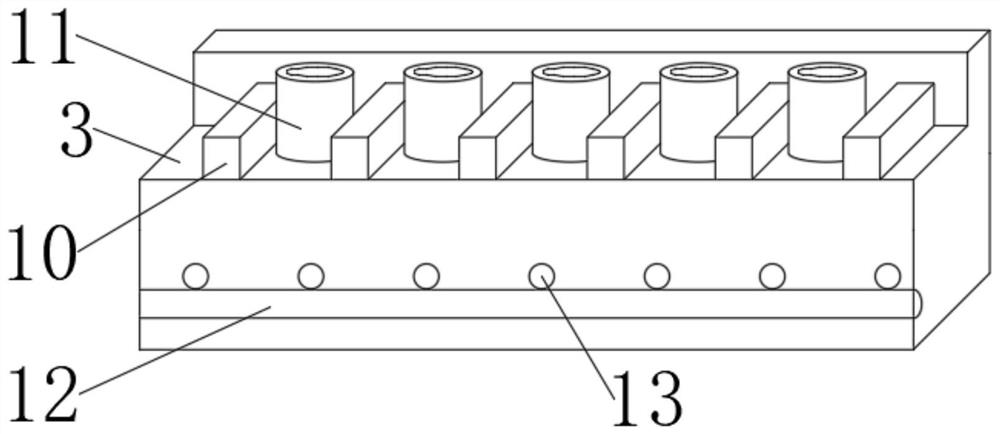

[0029] Such as Figure 1-Figure 4 As shown in the figure, a prefabricated integrated floor finish panel that is easy to lift includes a floor panel 1, an insertion slot 3 and a lifting ring 2, the upper four corners of the floor panel 1 are provided with lifting rings 2, and the upper side and four sides of the floor panel 1 are integrally formed There are insertion slots 3, and the inner sides of the insertion slots 3 are equidistantly integrally formed with limit blocks 10, and the positions between the limit blocks 10 are provided with planting reinforcement sleeves 11, the lower end of the suspension ring 2 is provided with studs 7, and the outside of the studs 7 is provided with Fixed sleeve 5, the inner side of fixed sleeve 5 is provided with thread groove 6 corresponding to the position of stud 7, the outer side of fixed sleeve 5 is provided with steel bar sleeve 8, the inner side of steel bar sleeve 8 is drilled with steel bar slot 9, fixed sleeve 5, steel bar sleeve 8,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com