Over-point automatic starting rotating shaft

A rotating shaft and automatic technology, applied in the direction of pivot, shaft and bearing, pivot connection, etc., can solve the problems of poor hand feeling, slow opening speed, etc., and achieve the effect of simple structure, quick pop-up, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

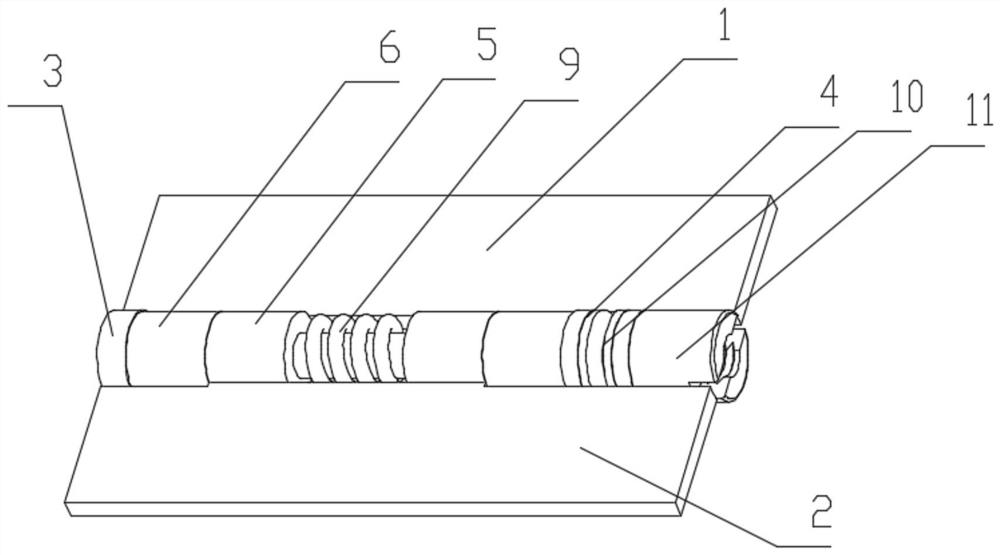

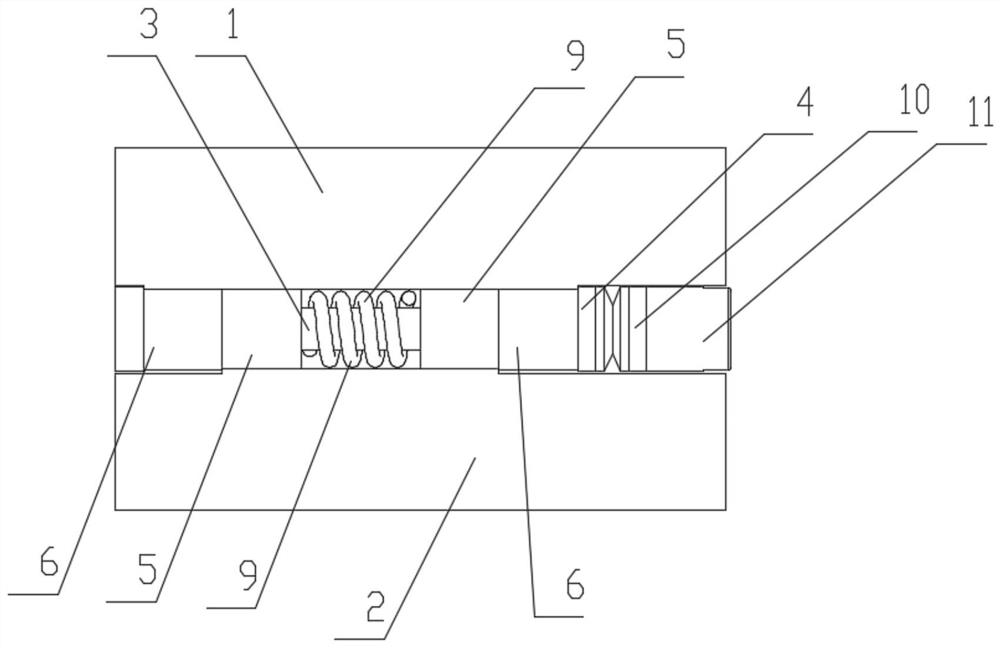

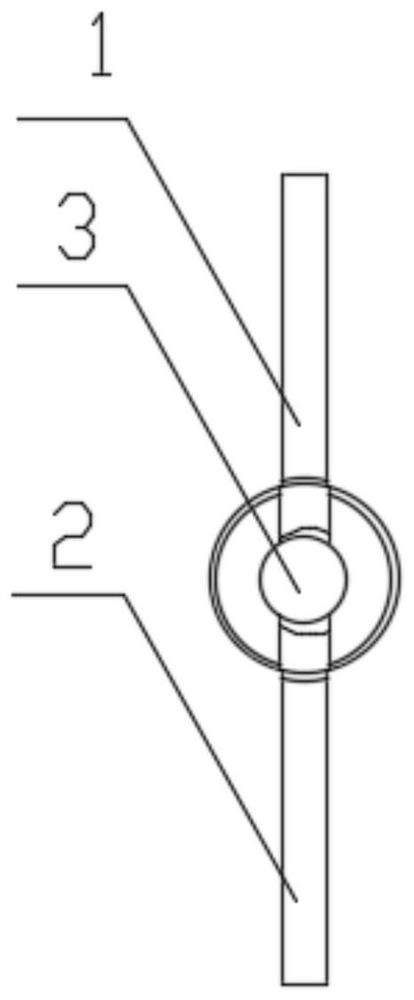

[0019] Embodiment: A kind of cross-point automatic starting and rotating shaft 3, including the fixed piece 1, the movable piece 2, the rotating shaft 3, the cam, the concave wheel 4, the elastic member and the resistance providing device 10, and the fixed piece 1 is provided with at least one first bushing 5. The movable piece 2 is provided with at least one second bushing 6, and the first bushing 5, the second bushing 6, the cam and the concave wheel 4 are axially and slidably sleeved on the outside of the circumference of the rotating shaft 3, so that The two ends of the rotating shaft 3 are respectively formed with radially outwardly expanding stoppers, and the stoppers are tightly abutted against the axial direction of the overall stacked structure formed by the first bushing 5, the second bushing 6, the cam and the concave wheel 4. At both ends, the second shaft sleeve 6 can rotate relative to the rotating shaft 3, one of the cam and the concave wheel 4 is positioned in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com